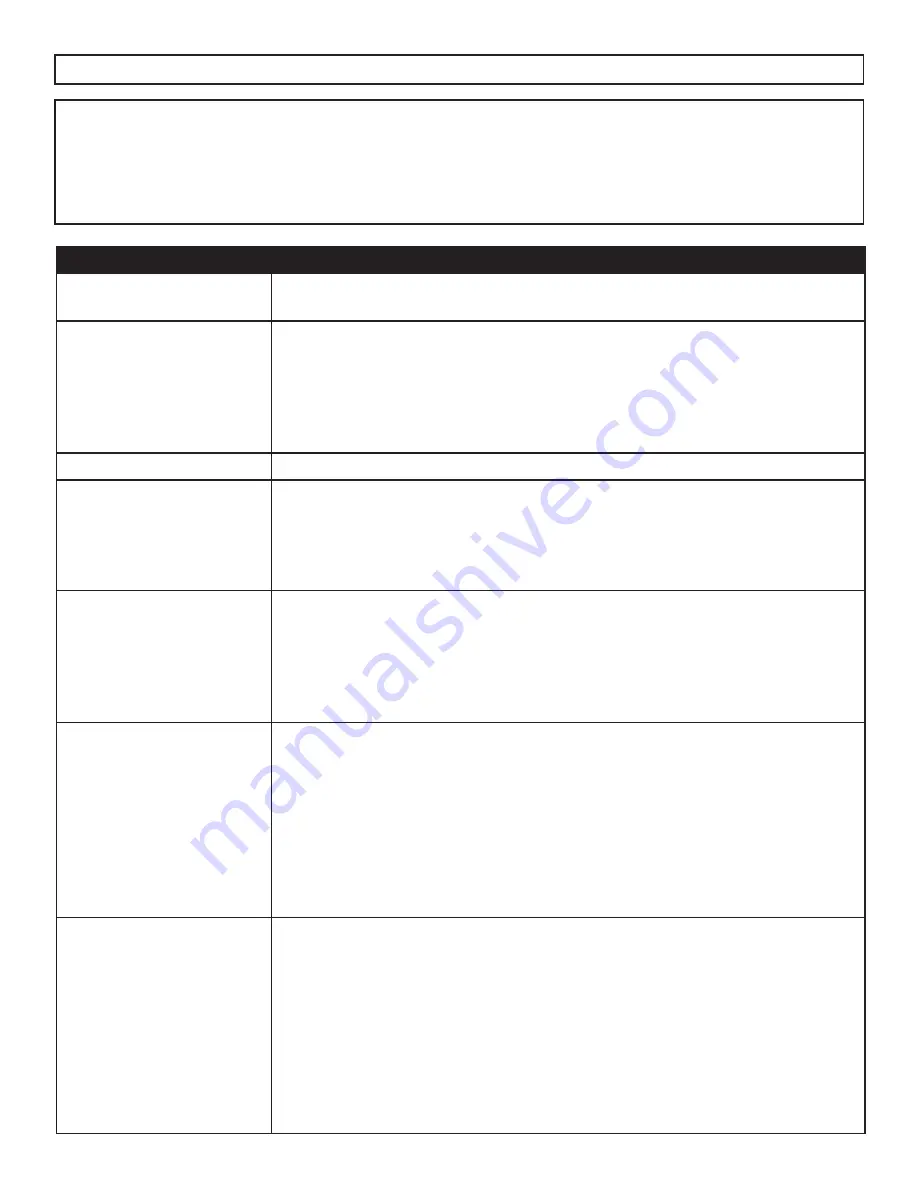

TROUBLESHOOTING

Danby Consumer Care: 1-800-263-2629

Hours of operation:

Monday to Thursday 8:30 am - 6:00 pm Eastern Standard Time

Friday 8:30 am - 4:00 pm Eastern Standard Time

Information in this manual is subject to change without notice.

13

PROBLEM

POSSIBLE CAUSE

The unit does not operate

• Not plugged in

• The circuit breaker tripped or blown fuse

Turns on and off

frequently

• The room temperature is hotter than normal

• The door is open too often

• The door is not closed completely

• The temperature control is not set correctly

• The door gasket does not seal properly

• The unit does not have proper clearance

Vibrations

• Check that the keg cooler is level

The keg cooler seems to

make too much noise

• The rattling noise may come from the fl ow of refrigerant, which is normal

• Gurgling, caused by liquid refrigerant cycling is normal

• Contraction and expansion of the inside walls may cause popping and

crackling noises

• The keg cooler is not level

The door will not close

properly

• The keg cooler is not level

• The door was reversed and not properly reinstalled

• The gasket is dirty

• The shelves or stand are out of position

• The keg is not properly centered in the unit

• The casters are not attached

Excessive beer foam

• Ensure the beer line hose from the tower and the CO

2

air line hose from

the CO

2

regulator are attached to the correct connections on the coupler;

beer line to the top of the coupler, CO

2

air line to the side of the coupler

• Check that there are no leaks in any connections

• Ensure that the reed valve in the CO

2

connection at the coupler has a

hole in it

• The

CO

2

pressure may be set too high; try turning the pressure down

• Ensure that the check valve is inserted into the coupler

• Ensure the beer lines are clean

Weak beer fl ow

• Ensure the beer line hose from the tower and the CO

2

air line hose from

the CO

2

regulator are attached to the correct connections on the coupler;

beer line to the top of the coupler, CO

2

air line to the side of the coupler

• Check that there are no leaks in any connections

• Ensure that the reed valve in the CO

2

connection at the coupler has a

hole in it

• The

CO

2

pressure may be set too low; try turning the pressure up

• Ensure there are no bends or kinks in any of the hoses that could impede

fl ow

• Ensure the beer lines are clean