3. Level and Position Range

Level range by adjusting the 2 leveling legs with a wrench. Note: A minimum clearance of 1/8” is required between the bottom

of the range and the leveling leg to allow room for bracket.

Use a spirit level to check your adjustments. Slide range back into position. Check that rear-leveling leg is inserted into and

fully secured by the Anti-tip bracket by grasping the top rear edge of the range and carefully attempt to tilt it forward.

4. Provide an adequate gas supply

This unit is pre-set to operate on 4” natural gas manifold pressure. A convertible pressure regulator is connected to the

manifold and must be connected in series with the gas supply line. If the LP/Propane conversion kit has been used, follow

instructions provided with the kit for converting the pressure regulator to LP/Propane use.

Care must be taken during installation of range not to obstruct the flow of combustion and ventilation air.

For proper operation, the maximum inlet pressure to the regulator should be no more than 14 inches of water column

pressure. The inlet pressure to the regulator must be at least 1 inch greater than regulator manifold pressure. Example: If

regulator is set for natural gas 4-inch manifold pressure, inlet pressure must be at least 5 inches; if regulator has been

converted for LP/Propane gas 10 inches manifold pressure, inlet pressure must be at least 11 inches.

Leak testing of the appliance shall be conducted according to the instructions in step 6g.

The gas supply line should be ½” or ¾” I.D.

5. Seal the openings

Seal any opening in the wall behind the range and in the floor under the range after gas supply line is installed.

6. Connect the range to the gas supply

To prevent leaks, put a pipe joint sealant on all male (outside) pipe threads.

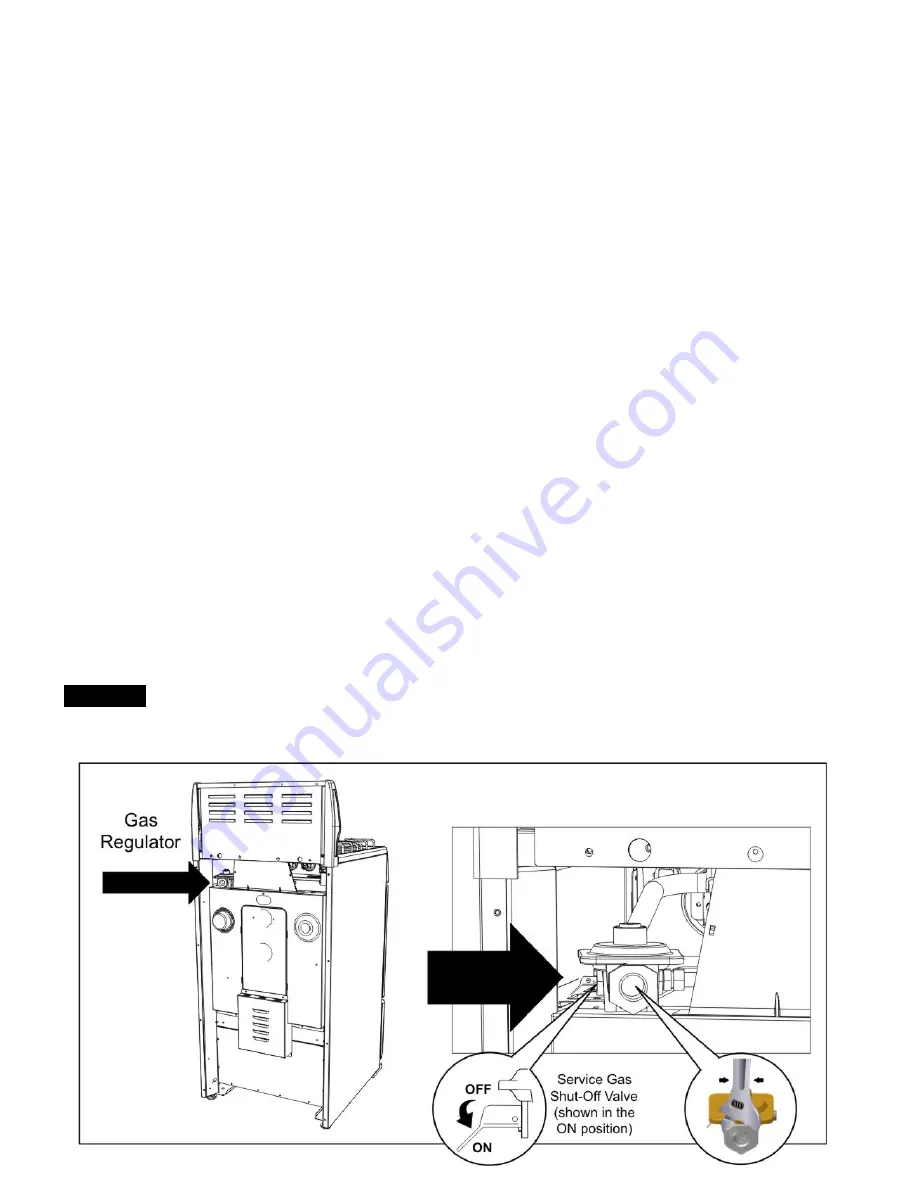

Your regulator is in the location show below.

CAUTION

Do not allow that pressure regulator turn on pipe when tightening fittings. Be sure of holding the

regulator with an adjustable wrench to prevent the internal tubing suffering damages or leaks.