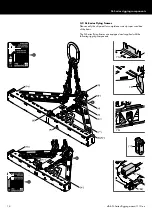

SL-Series rigging components

Z5704 GSL Compression set

Set

Including

Z5704

GSL Compression

set

(44 kg/97 lb)

[1a]

Z5703

GSL Compression frame

(18.6 kg/41 lb).

[2]

Z5709

SLCompression chain 2.5 t

(12.1 kg/26.7 lb).

[3]

B2447.073

Compression grab link

(1.4 kg/3.1 lb).

[4]

B2447.072

Lever hoist (7.5 kg/16.5 lb).

[5]

B2447.074

Compression frame master link

(3.5 kg/7.7 lb).

[6]

B2447.075

Chain bag (0.75 kg/1.65 lb).

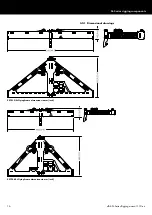

Z5724 KSL Compression set

Set

Including

Z5724

KSL Compression

set

(41 kg/90.4 lb)

[1b]

Z5725

KSL Compression frame

(16 kg/35.3 lb).

[2]

Z5709

SL Compression chain 2.5 t

(12.1 kg/26.7 lb).

[3]

B2447.073

Compression grab link

(1.4 kg/3.1 lb).

[4]

B2447.072

Lever hoist (7.5 kg/16.5 lb).

[5]

B2447.074

Compression frame master link

(3.5 kg/7.7 lb).

[6]

B2447.075

Chain bag (0.75 kg/1.65 lb).

d&b SL-Series Rigging manual 1.10 en

13