A-Series rigging components

2.4.3 Setting the splay angle(s)

Splay angles between adjacent cabinets can be set in the range

from 20° to 40° in 5° increments resulting in a total coverage of

50° up to 70° for two cabinets, with a maximum total coverage of

150° for four cabinets.

Splay angles can also be set symmetrically or asymmetrically,

depending on the application.

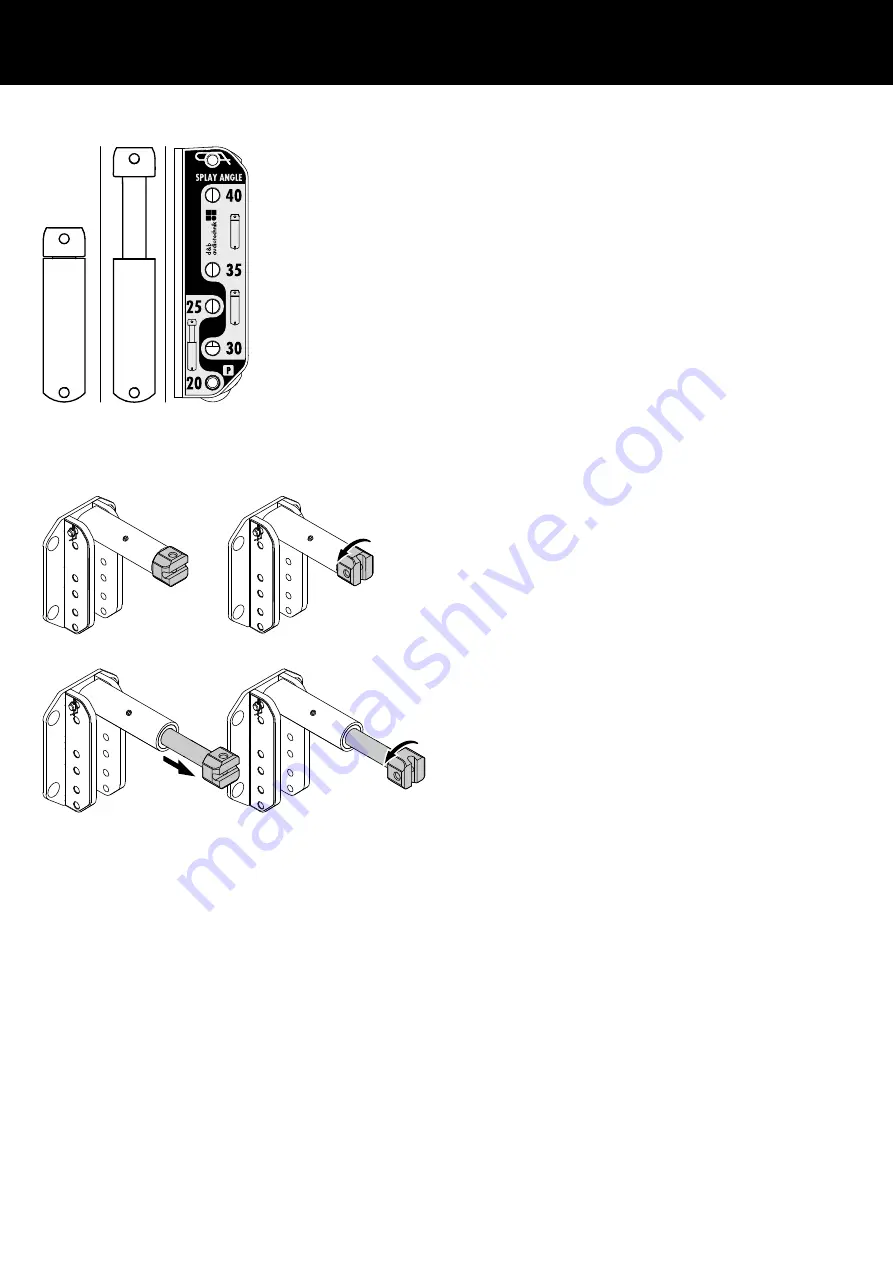

For this purpose, the Splay link provides two different lengths:

Standard or Extended.

Together with the corresponding

Hole grid on the rear rigging

strand, the desired splay angles can be set in the range from 20°

to 40° in 5° increments.

The Splay link is constructed as a cylindrical extender (we call it

the 'Trombone';).

The extension tube head can be turned counter clockwise by 90°

and back again.

To change between the Standard and Extended positions, proceed

as follows:

Standard length

1. Fold out the Splay link as previously described.

2. Turn the extension tube head counter clockwise by 90° to fix

the standard length of the Splay link.

Extended length

1. Fold out the Splay link as previously described.

2. Pull out the extension tube to its stop position.

3. Turn the extension tube head counter clockwise by 90° to fix

the extended length of the Splay link.

Standard | Extended | Hole grid

Splay link lengths and correlation to the hole grid on the rear rigging strand.

d&b Z5456 Rigging manual 1.1 en

9