1-1/4" (32mm) + POST DEPTH

Post depth

measurement

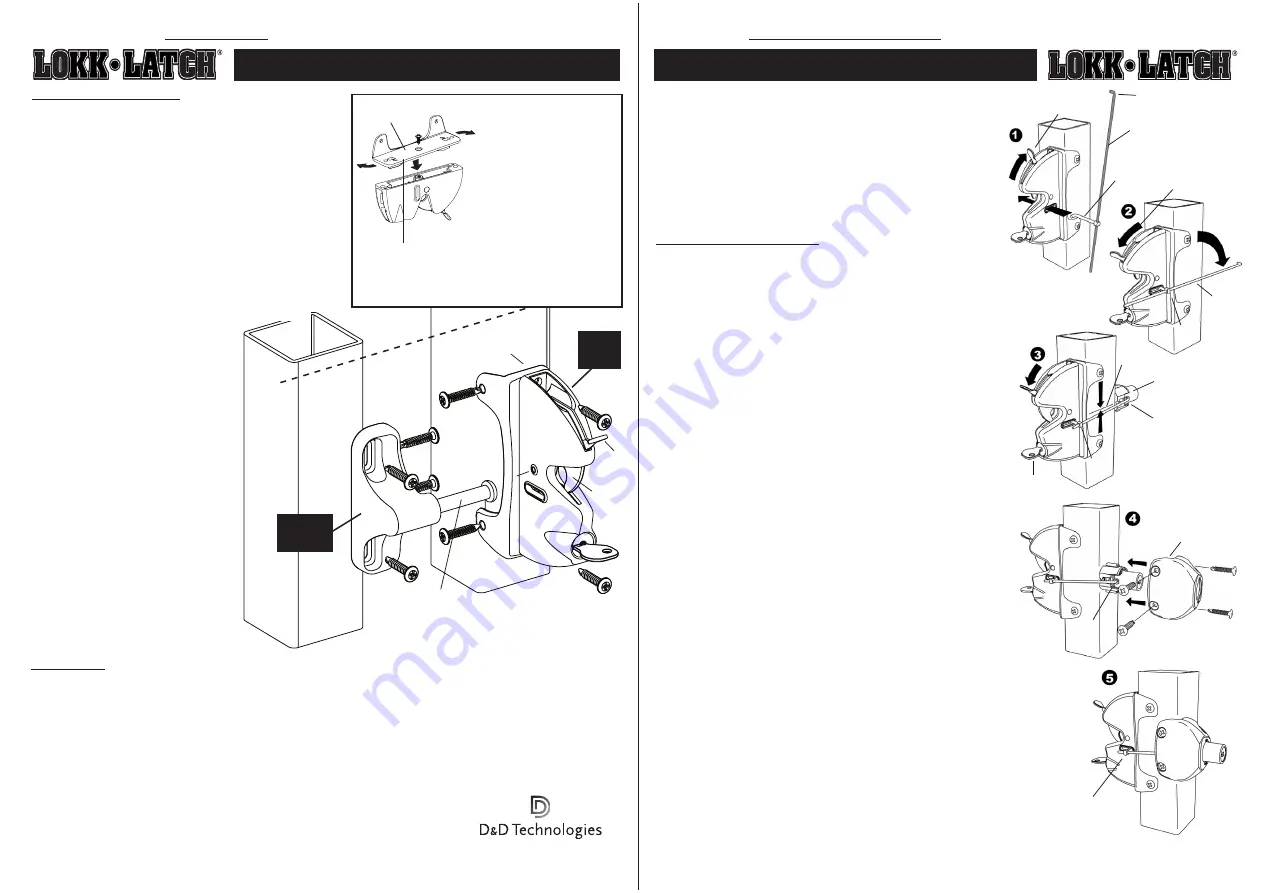

STEP #2 — EXTERNAL ACCESS KIT

STEP #1 — MAIN LATCH BODY

Key

Tongue

FENCE

POST

GATE

FRAME

Ensure gate frame & latch

post are aligned

LATCH

BODY

STRIKER

BODY

Striker Bolt

Post Bracket

INSTALLING THE POST

BRACKET:

Follow this procedure for installing

both Post Brackets.

If using the Post Bracket with side

legs, first determine the correct

handing. Insert the Post Bracket

into the back of the latch body

at a slight angle. Rotate the Post

Bracket in the direction of the

arrows until the plate snaps firmly

in alignment with the latch body.

Then insert the single short screw.

AUSTRALIA: Unit 6, 4-6 Aquatic Dr, Frenchs Forest NSW 2086

USA: 7731 Woodwind Drive, Huntington Beach, CA 92647

®

1-1/4" (32mm) + POST DEPTH

Post depth

measurement

2.

Secure the Latch Body using four

wafer-head,

self-drilling screws.

3.

Locate the Striker Body on the gate frame.

Close the gate. Align the Striker Bolt in the

centre of the latch tongue (i.e. align the Bolt

with the center of rivet). Hold the Striker Body

in place and mark the four fixing holes in the

center

of the fixing slots.

4.

Secure the Striker Body to the gate by fixing

the remaining self-drilling screws in the center of

all four slots. (The Striker is adjustable vertically

at any time as required.)

5.

Check latching operation to ensure smooth,

reliable closure. Your LOKK•LATCH is now ready

for use.

LLINSTR0016PA •instr_LLS2_26/4/07

Release

Knob

Post Bracket

Rivet

Rivet

1.

Determine the approximate height/location of

the Latch Body on the fence post. Mark the four

fixing holes. (Always predrill metal

using the

5

/

32

" [4mm] drillbit.)

www.ddtechglobal.com

For Lokk•Latch only installation , follow Step #1

▼

For latch with External Access Kit , follow Step #1, then Step #2

▼

INSTALLATION PROCEDURE

• This latch is designed to be fitted to the “opening” side

of the gate. See notes at right re "handing"

• Ensure the gate frame and the latch post are in

alignment (no offset). See dotted line.

• Depending on the model you purchased, the package may contain one or

two Post Brackets. Both brackets are suitable for metal gates. The bracket with

two side legs is ideal for wood & vinyl gates, but can be used on metal gates

as well.

Gap between fence post and gate:

Latch Only:

Post Bracket (No side fixing legs):

3

/

8

"–

1

3

/

8

" (9.5–35mm)

Post Bracket (With side fixing legs):

3

/

8

"–

1

1

/

8

" (9.5–29mm)

Post sizes: 1"–6" (25–150mm)

Tools:

Electric or cordless drill,

5

/

32

" [4mm] drillbit for pre-drilling

metal, 3

1

/

2

" Phillips #2 driver shaft for screws.

Determine

the correct

handing

INSTALLATION PROCEDURE

1.

Measure the post depth and add 1

5

/

16

” (33mm) to that

measurement. Wind the Adjustor Lever along the Adjustor Rod

so that the Bent End of the Adjustor Rod is this distance away from the

Adjustor Lever (see diagram 1).

2.

With the latch in the unlocked position, prop the gate open. Slide the

Release Knob to the up position at the rear of the Latch Body. Take the

adjustable Rod and, holding it vertically, slide the Adjustor Lever through

the slot in the side of the Latch Body as shown in diagram 1. Be sure the

bent end of the Adjustor Lever protrudes completely through to the other

side of the Latch Body.

3.

Lower the Release Knob to the down position so that it encloses the

Adjustor Lever. Turn the key to lock the Release Knob in place. Rotate the

Adjustor Rod to the horizontal position as shown in diagram 2.

4.

To aid with installation, the Push Button is locked. Place the Push Button

Assembly against the opposite side of the Fence Post from the Latch Body

and center it to the Latch Body (see diagram 3). Place the bent return of

the Adjustor Rod into the hole on the side of the Push Button as shown in

diagram 3 & 4. This will leave the Adjustor Rod at a slight angle, which is

normal. Ensure the Adjustor Rod is at the correct length. Rotate the Adjus-

tor Rod, if required, for fine adjustments. The Adjustor Lever within the

Latch Body must be at the end of the slot closest to the Fence Post. Mark

the angle and position of the Adjustor Rod using a pencil (see diagram 3).

5.

With the bent end of the rod firmly inside the hole on the Push Button,

slide the Fixing Shroud over the Push Button until the Fixing Shroud is

firmly against the Fence Post (see diagram 5). If the Push Button has gone

out of position, realign the Adjustor Rod to the mark you earlier made with

the pencil.

6.

Secure the Fixing Shroud to the Fence Post by using the four self-drilling

screws included (Always predrill metal by using the

5

/

32

” [4mm] drill bit.)

Unlock the Push Button and check for smooth operation. Cut off any excess

Adjustor Rod to approximately

1

/

4

” (6mm) from the Adjustor Lever.

File off any sharp edges to make smooth.

The External Access Kit is ready for use.

(Note: Locking the External Access Kit only locks the Push Button.

It does not lock the Latch Body, which is lockable separately).

Adjustor Rod

Adjustor Lever

Fence Post

Cut off any excess

Adjustor Rod

Bent Return

Release Knob

Push Button

Fixing Shroud

Adjustor Rod

Adjustor Lever

Release Knob

Adjustor Lever

Turn Key to Lock

Latch

Body

Bent Return

Pencil Line

Bent End

The External Access Kit (EAK) allows a gate to be opened and

locked from the opposite side to the latch. When installed, it is

connected to the Latch Body by an Adjustor Rod.

Gap between fence post and gate frame:

Latch + EAK:

Post Bracket (No side fixing legs):

9

/

16

" - 1

3

/

8

" (14.3 - 35mm)

Post Bracket (With side fixing legs):

9

/

16

" -1

1

/

8

" (14.3 - 29mm)

MAINTENANCE:

REMOVE KEY/S FROM LOCK/S AFTER USE.

Do not lubricate the latch with petroleum-based lubricants at any time - use only

powdered graphite.

Ensure all screws are tightened firmly and that the Latch Body and/or Access Kit is kept free of dirt, sand and other debris which

could impair reliable performance.

WARRANTY & LIMITATION OF LIABILITY:

D&D Technologies’ (“D&D”) products are warranted to be free of defects in materials and workman-

ship to the original purchaser for as long as he/she owns the product. This product will operate properly, and warranty is valid, only if installed in

accordance with the instructions and specifications shown. If a structural defect appears, the original purchaser may return the item, freight prepaid,

together with proof of purchase to D&D or its approved international agents. D&D or its agent will, at their discretion, repair or replace the defective

item or part without charge to the purchaser. THIS WARRANTY SHALL NOT APPLY WHEN the product has been tampered with, when repairs or attempted

repairs have been made by unauthorized persons, where the item has been subjected to misuse, abuse, accident or damage in transit, or where

the installer has not followed the instructions set out during installation, operations, or Maintenance requirements.

IN NO EVENT SHALL THE COMPANY BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES. No warranty is

given other than that set out above. No other express or implied warranties (including statutory warranties)

apply, other than warranties which may not be legally excluded.