AK-CT

450A

User

Guide RS8GR602 © Danfoss 2016-10

9

Fan

Pulse control

To obtain energy savings it is possible to pulse control the power

supply to the fans at the evaporators.

Pulse control can be accomplished in one of the following ways:

- during the thermostat’s cutout period (cold room)

- during night operation and during the thermostat’s cutout

period (appliance with night lid)

A period of time is set as well as the percentage of this period of

time where the fans have to be operating.

Cutout of fans during plant breakdowns

If the refrigeration in a breakdown situation stops, the

temperature in the cold room may rise quickly as a result of the

power supply from large fans. In order to prevent this situation the

controller can stop the fans if the temperature at S5 exceeds a set

limit value.

Fan pause

When the setting P65 is set to a value greater than 0, the fans will

stop while the night blind is rolling down.

Eco-mode

When the night blind is down, the fan speed can be reduced.

Eco-mode is not allowed if the heating function has been

activated.

When Eco-mode is enabled, relay DO8 will be activated.

Light function

The function can be used for controlling the light in a refrigeration

appliance or in a cold room. It can also be used for controlling

a motorised night blind.

The light function can be defined in more than one way:

- The light is controlled via a signal from a door contact.

The light will remain on for 2 minutes after the door has been

shut.

- The light is controlled via the day/night function.

- The light is controlled via the data communication from

a system unit.

Here there are two operational options if data communication

should fail:

- The light can go ON.

- The light can stay in its current mode.

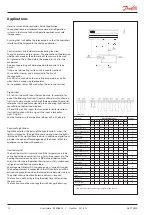

• Two signals,

both

of which can be on before the light goes on.

One can be a DI contact signal at the appliance (fx DI3) and the

other can be via data communication or a voltage signal.

Voltage signal

must

be activated on DI7.

The light is switched off when "r12" (Main switch) is set to off

(see o98).

The light is switched off when the appliance cleaning function

is activated.

If an override of the light is desired, this can be done via pulse

pressure on a DI input + setting = 19.

Extra light (light 2)

Light 2 can also be activated by one DI input, e.g. DI4.

It can also be controlled with two signals. For two signals,

the second signal must be sent with a voltage signal on DI8.

Period time

Light 2

(extra light)

controlled by

DI8 and fx DI4.

Light 1

controlled by

DI7

and fx DI3.

Override of light 1