AK-CH

650

Capacity

controller RS8ER302 © Danfoss 2016-02

91

The function takes effect at a value which is 3 K below the set

value. At this time the entire condenser capacity is cut in at the

same time as 33% of the compressor capacity is cut out (but min.

one step). This is repeated every 30 seconds. The alarm function is

activated.

If the temperature (pressure) rises to the set limit value, the

following will happen:

- all compressor steps will immediately be cut out

- the condenser capacity will remain cut in

The alarm will be cancelled and renewed cutin of compressor

steps is permitted when the following conditions are met:

- the temperature (pressure) falls to 3 K below the limit value

- the time delay for restart has been passed.

Time delay

There is a joint time delay for “Monitoring of max. discharge gas

temperature” and “Min. suction pressure”.

After a cutout, regulation cannot be recommenced until the time

delay has been passed.

The time delay starts when the Sd temperature has again dropped

to 10 K below the limit value or P0 has risen above the P0 min.

value.

Frost-proofing input

A digital input can receive a signal from an external frost-proofing

signal.

If the frost-proofing signal is activated, the entire compressor

capacity is disengaged and pump operation continues.

Re-engagement of the compressors is not permitted as long as

the frost-proofing signal is active.

Startup procedure

The controller contains functions that ensure the proper interac-

tion of pumps, compressors and injection on startup.

Pumps

On startup, the pumps must accelerate a large brine mass to nor-

mal flow rate before the compressors are allowed to start.

In the controller there is an adjustable delay time, "Comp. Wait s",

which must expire before the first compressor can start.

Capacity limit

If too much compressor capacity is connected in the startup

situation, there is a risk that the compressors will drop out at low

pressure.

To prevent this situation, a capacity limit is input on startup of

the system, so only the first capacity step is engaged in a set time

period (set via "operation time first step").

Delay on P0 min cut-out

As further protection against cut-out at low pressure during star-

tup, it is possible to delay the "P0 Min" cut-out.

The delay time can be set via "P0 Min. fors".

S4 Alarm thermostat

The function is used to emit an alarm if the S4 brine temperature

becomes critical.

Alarm limits and delay times can be set for high and low tempera-

ture.

An alarm is emitted if the set limit is exceeded, but only after the

delay time has expired.

There are no alarms when refrigeration has been stopped due to

the main switch being set to Off.

Alarm limits

The alarm limits for high and low S4 temperature are set as abso-

lute values in °C.

The alarm limits are not affected during night operation or on

external reference displacement via a voltage signal.

Time delays

Three time delays are set:

• At too low a temperature

• At too high a temperature during normal control

• At too high a temperature during pull-down

- After activation of an internal or external main switch

- During defrosting

- After a power failure

The time delay during pull-down applies until the S4 temperature

drops below the upper alarm limit

S4 status information

To be able to assess how well the system is operating, the follow-

ing can be read:

• Min, Max and average S4 temperature for the last 24 hours

• Operation time outside alarm limits within the last 24 hours, as a

percentage

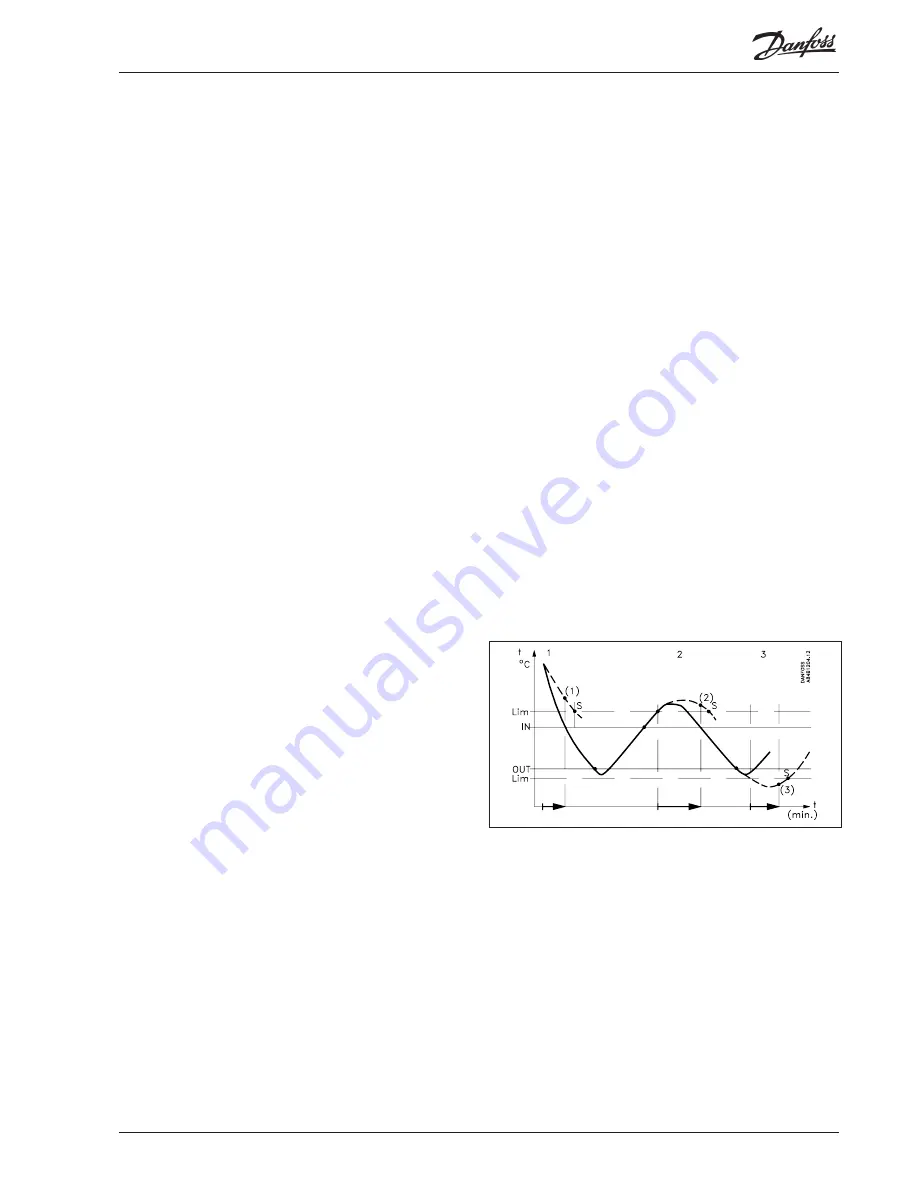

Example

Curve 1: Pull-down phase

(1): The time delay is passed. The alarm becomes active.

Curve 2: Normal control where the temperature becomes too high

(2): The time delay is passed. The alarm becomes active.

Curve 3: The temperature becomes too low

(3): The time delay is passed. The alarm becomes active.