18 DKDHR

VI.GP.V2.02

Danfoss District Energy

9.0 Filling, Start-up

Prior to the Akva Lux II VX installation all its pipes and connections

should be cleaned and rinsed. After that the dirt strainers should

be cleaned.

Due to vibrations during transport all connections must be checked

and tightened before filling and start-up.

Before filling up the system and first start-up, check if:

- pipes are connected according to the circuit diagram,

- expansion vessel is connected,

- heat meter is mounted,

- shut-off valves are closed,

- threaded and flanged connections are tightened.

Filling:

The filling valve(s) are used for filling up the heating circuit.

•

The pump must be switched off when filling the system with

water.

•

Open the ball valves for the HE supply and return flow as well

as the ball valve for DCW.

•

Carefully open the fill valve(s) and fill the system with water

and at the same time vent the system.

•

Fill heat exchanger / the system with water until the mano-

meter shows a working pressure, which corresponds to the

system 5 m (approx. 1.2 - 1.5 bar).

•

Close the fill valve(s).

•

Then open the ball valves for the DH supply and return flow

and heat up the system.

•

After filling and heat- up of the system, it should be vented by

means of the air vents on the substation and on the radiators.

•

Then switch on the pump(s).

10.0 Manometer and refilling

If the pressure drops below 1 bar, water must be added to the

system. The operating pressure should never exceed 1.5 bar.

(The safety valves open at 2.5 bar)

If the system pressure drops dramatically within a short time, or

if you experience that it is necessary often to refill the system,

the heating system should be examined for leaks, - this includes

checking the factory set pressure of the expansion vessel.

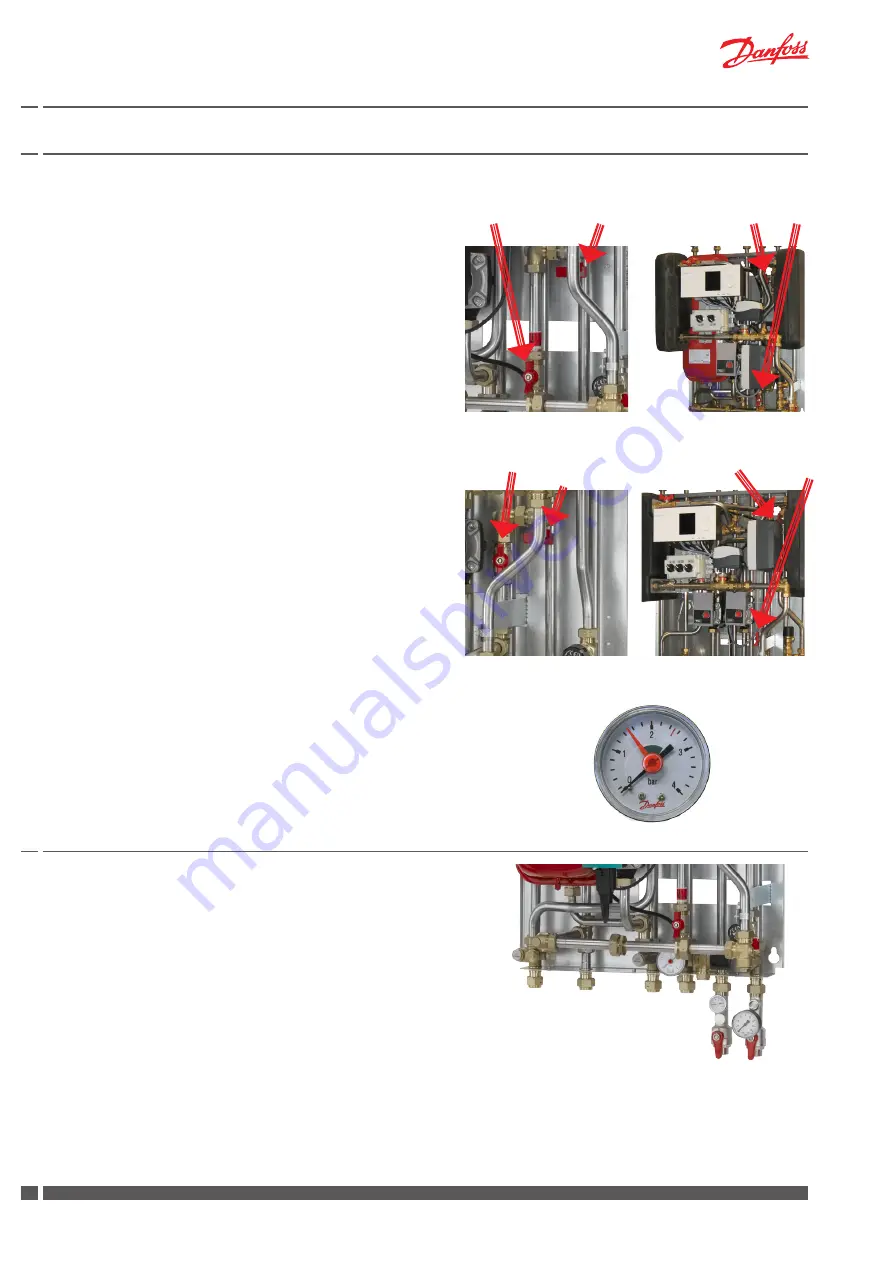

Filling valves

Akva Lux II VX2

Filling valves

Akva Lux II VX2-E

Filling valves

Akva Lux II VX3

Filling valves

Akva Lux II VX3-E