Bearings and lubrication

The grease relubricable bearings need regular greasing. Follow the relubrication interval and instructions described in

this Chapter.

Grease can cause skin irritation and eye in ammation. Follow all safety precautions speci ed by the manufacturer of the

grease.

Stop the automatic greasing if the electric machine is stopped.

Make sure that the automatic greasing and the oil lubrication function correctly after you start the electric machine.

The expression of L

10

in bearing lifetime information is a standard way of expressing the lifetime

and means the time period at the end of which 90% of the bearings are still reliably

working. Grease relubricable bearings (BHS option) need regular greasing. This is due to the

limited lubricant (grease) lifetime in operation conditions, and is shorter time period than the

actual bearing lifetime.

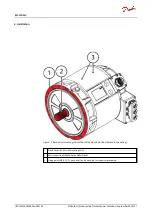

The bearing type for electric machine is 6009 C3. See the recommended lubricant in Chapter

Recommended lubricants.

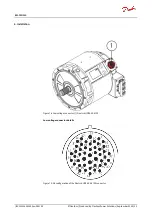

Bearing relubrication

Beware of rotating parts. Do not touch the electric machine during operation.

The surface of the electric machine can be hot. Use correct protective equipment (heat resistant gloves) when you

handle the electric machine.

The information of bearing lifetime and bearing grease lifetime are estimations only to provide a magnitude of them. The

bearing lifetime and bearing grease lifetime in customer application may vary. Danfoss is not responsible for the actual

bearing lifetime in use. For further information contact Danfoss representative.

The maximum relubrication interval in operation is 6 months. The amount of grease per relubrication is 20 g.

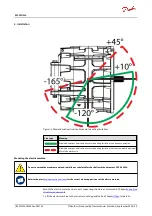

The relubrication interval depends on the used rotation speed and bearing temperature, and is

presented in Figure below. The different curves represent different bearing temperatures. The

higher the temperature is and the higher the rotation speed is, the lower the relubrication interval

is.

EM-PMI240

8. Maintenance

| BC355256345493en-000103

©

Danfoss | Produced By: Danfoss Power Solutions | September 2020 | 43

Summary of Contents for EM-PMI240

Page 1: ...User Guide Motor Generator EM PMI240 danfoss com...

Page 59: ......