© Danfoss | Climate Solutions | 2023.07

AX450533577373en-000201 | 9

Assembly

HGZ7/1620+1860

X

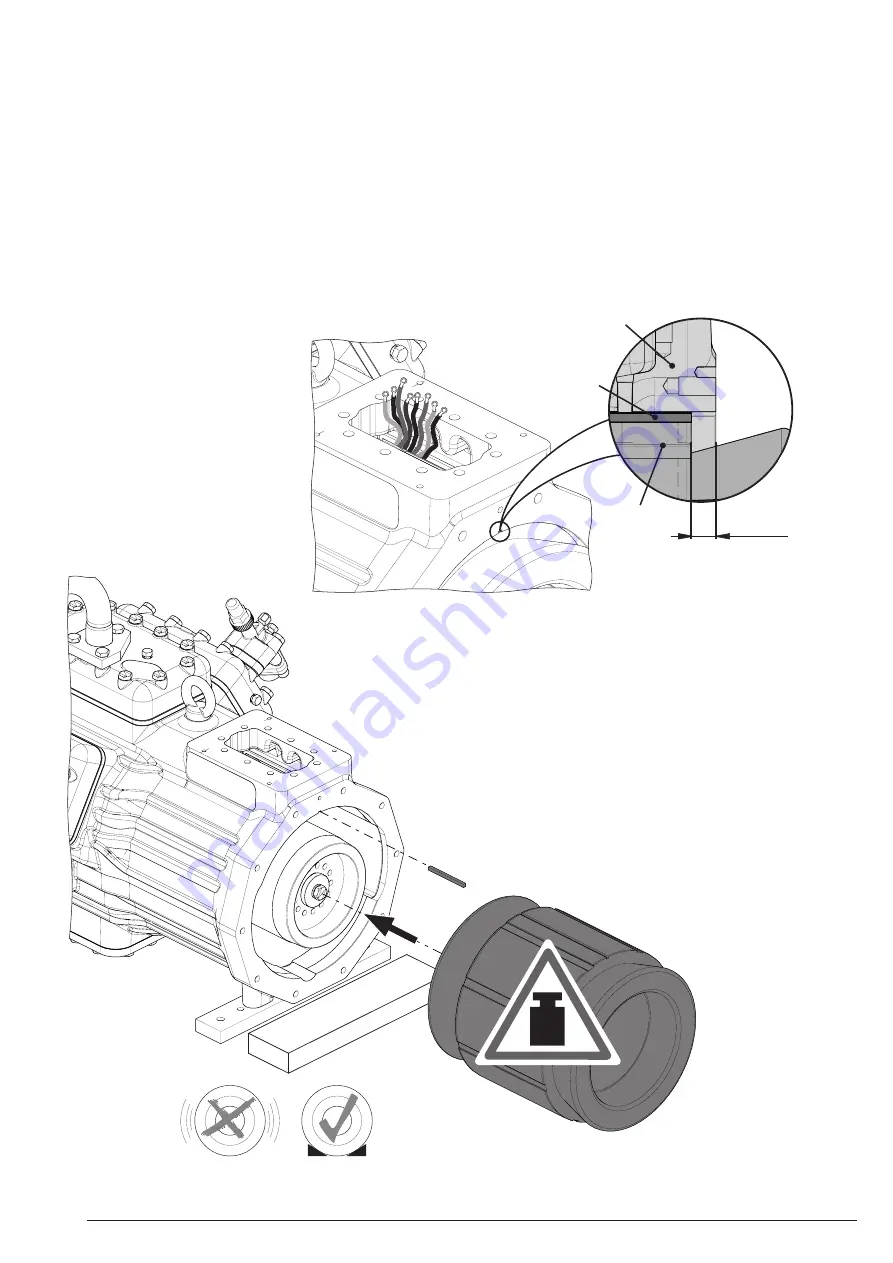

Do not damage any cables or component parts.

Push the stator with the cables leading into the motor housing to a

depth of 13.5 mm. At the same time, carefully pull the cables upwards through the terminal board opening.

¾

Align the stator such that the feather key can be pushed in the the groove on the motor housing flush with the stator.

¾

Fix the feather key and stator in this position using the new stator screws, as described on page 10.

max.

75kg

13,5 mm

Motor housing

Feather key

Stator