System design recommendations

Oil level regulator

Oil level regulator monitors the oil level and

controls oil injection by switching the solenoid

valve on and off to maintain an acceptable

oil level in the compressor crankcase. When

crankcase oil level cannot be restored within a

period of time (setting value), the alarm contactor

will be activated and stop the compressor to

protect it from damage (some oil level regulator

do not have an alarm function).

According to the function, there are three

types of oil level regulator: electronic,

electromechanical and mechanical. For a

high-pressure oil reservoir system, Danfoss

recommends individual electronic oil control

regulators rather than the mechanical float ball

oil regulator system for effective oil regulation.

To ensure ideal pressure equalization, the suction

header must be symmetrical and the lines from

the suction header to each compressor must be

short and identical. These recommendations are

not so critical when using an active system.

Danfoss recommends the following as necessary

for secure a suction header installation:

• The suction header should be adequately sized

for equal distribution of returning refrigerant gas

and oil to each individual compressor; also the

suction header should be installed horizontally.

• The gas velocity in the suction header must be a

maximum of 4 m/s.

• The suction line and the suction header must be

insulated to limit suction gas superheat.

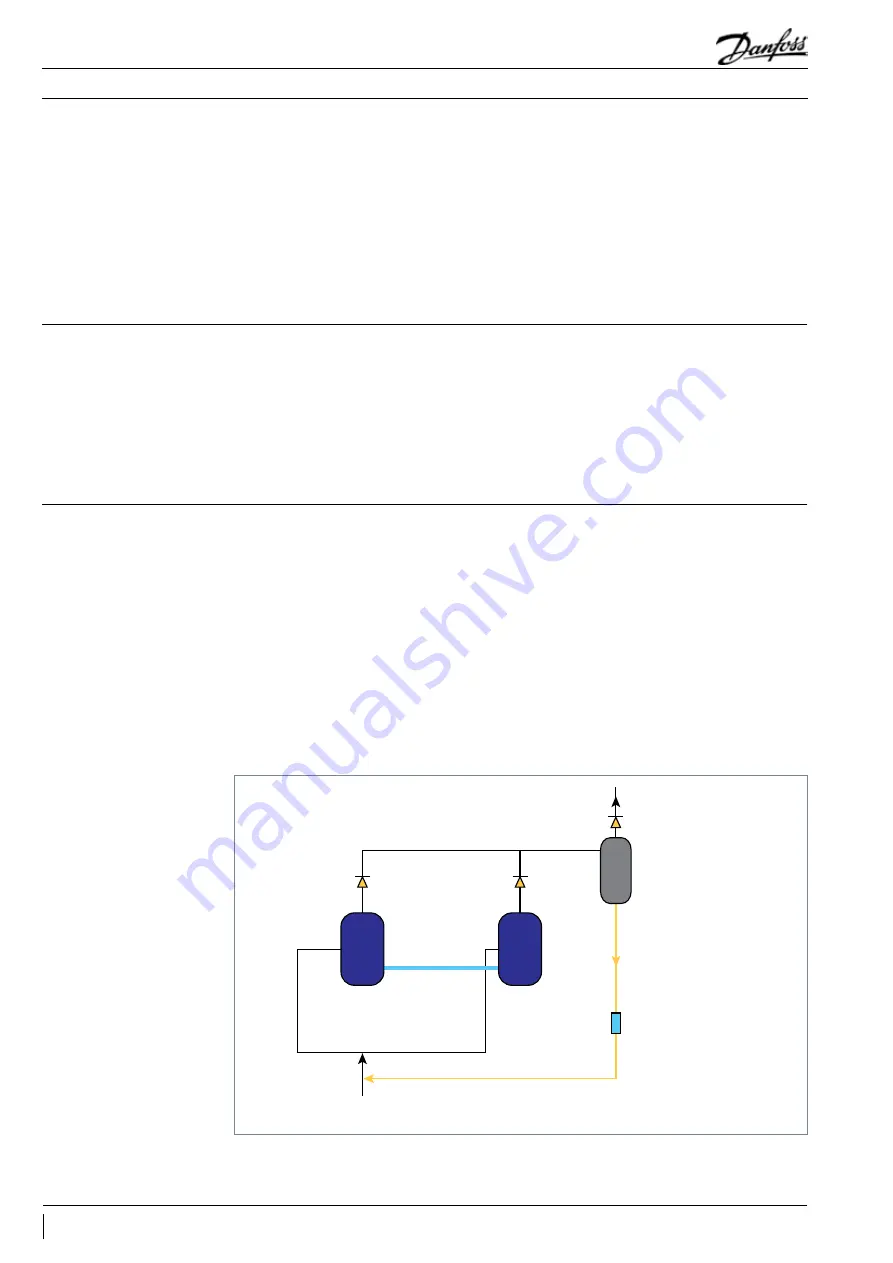

Passive system

Oil separator / oil

reservoir

Oil separator for passive

system

The role of the oil separator is to intercept the

mixed oil from the compressed refrigerant gas

and returns it back to the compressor to assure

efficient lubrication of its moving parts, and

also to improve the system’s heat exchangers’

efficiency. In our manifolding system, the oil

separator is necessary and is recommend to be

installed in the compressor discharge line as

shown below.

No oil separator category is included in this

guidelines. For more details, please refer to the

manufacture’s guidelines.

Regarding passive solutions, it is recommended

to use an oil separator with a floating-ball

valve. The floating-ball valve can control the

oil flow and act as a capillary in the oil return

line; therefore, there is no need to install an oil

capillary in the system.

Compressor 1

Compressor 2

Suction header

From evaporator

To condenser

Oil equalization

line

Non-return valve

Non-return valve

Oil separator with

floating-ball valve

Oil filter

48

FRCC.PC.035.A4.02

Application Guidelines

Manifold compressors