System design recommendations

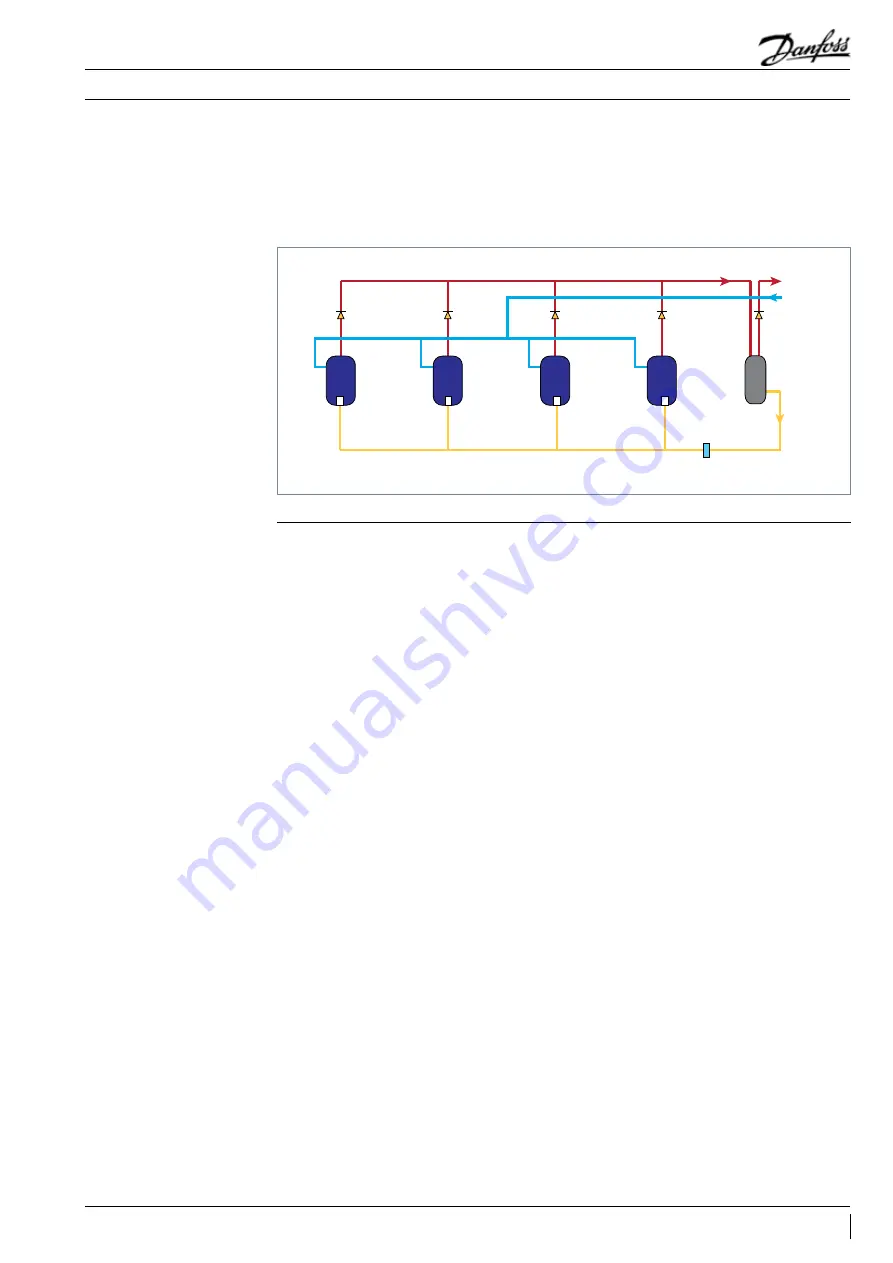

Active system

Oil separator and

reservior for active

system

When an active system is adopted by the

customer, the oil separator is always considered

together with oil reservoir.

Due to system design, loads and defrost

cycles, etc., there will be varying amounts of oil

returning to the oil separator. Because of this,

a safety reserve of oil is required for successful

operation of the active system.

High pressure

Low pressure

Non-return

valve

Suction

header

Non-return

valve

Non-return

valve

Non-return

valve

Combined oil

separator/reservoir

Oil filter

Non-return

valve

Compressor 1

Oil level regulator

Oil level regulator

Oil level regulator

Oil level regulator

Compressor 2

Compressor 3

Compressor 4

Danfoss recommends that high-pressure

systems (oil separator installed in high pressure

side) are configured in active solutions. These

systems store the oil in a common oil separator/

reservoir at compressor discharge pressure (see

the figure below). The advantage is that these

systems do not need a separated oil reservoir but

make use of a combined oil separator/reservoir

arrangement ,which normally results in a cost

saving over traditional low-pressure systems

(additional oil separator and oil reservoir installed

in low pressure side). From an application point

of view, high-pressure systems are more critical

than traditional low pressure systems and care

must be taken to make sure that the separator/

reservoir installed is of sufficient size and oil

content (as per manufacturer’s recommendation)

so that there is always oil stored. And pay special

attention to avoid discharge gas entering the

compressor oil sump, which could lead to some

negative effects such as higher discharge and oil

temperatures, less lubrication capability and the

loss of efficiency due to hot gas bypass.

49

FRCC.PC.035.A4.02

Application Guidelines

Manifold compressors