2.4GHz Receiver LED troubleshooting

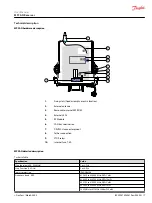

The troubleshooting LEDs are located on the receiver board or accessible on the outside. Use the

following table to identify faults and corrective action.

In order to reach the internal signaling, the receiver must be accessible, connected and the screws

located on the receiver lid must be unscrewed using the proper screw driver whenever the LEDs are not

externally visible.

The LEDs on the receiver board are POWER, STATUS, DIAG1, DIAG2, ORDER, RELAY, CANERR and CANRUN

in that order.

Please do check the following website for further information:

https://troubleshooting.dps-rct.com/en/customer-service-center

LED

Color and frequency

Pulse frequency

Description

Action

POWER

Green | continuous

Switched ON if powered

Check power supply if LED is

switched off.

STATUS

Blue | fast pulses

System is starting; establishing connection with

radio and EEPROM

Wait

Blue | continuous

Waiting for transmitter communication, coming

from ACTIVE STOP

Release STOP button and press

START on the transmitter.

Blue | slow pulses

Waiting for transmitter communication, coming

from PASSIVE STOP

Press Start on the Transmitter

Green | continuous

Working

Operate

Red | slow pulses

EEPROM module missing or corrupt

Check EEPROM and reprogram

if necessary

Red | double pulses

Radio communication error

Replace receiver

Red | triple pulses

Secondary micro error or error between micro

communication

Replace receiver

Red | 4 pulses

ERROR

Check DIAG1 LED

Red | 5 pulses

After 15 sec Not all expansion boards have been

initialized

Check CAN wiring and

Configuration(EEP or Expansion

ID#), Check Bus Termination.

Red | 1 Long + 1 short

pulse

CAN Signature ERROR

Check Signature in Compliance

Block and EEPROM are the

same.

User Manual

MPCAN Receiver

Troubleshooting

©

Danfoss | March 2022

BC292573933619en-000201 | 13