5

521B0881 DKCFN.PI.020.F1.02

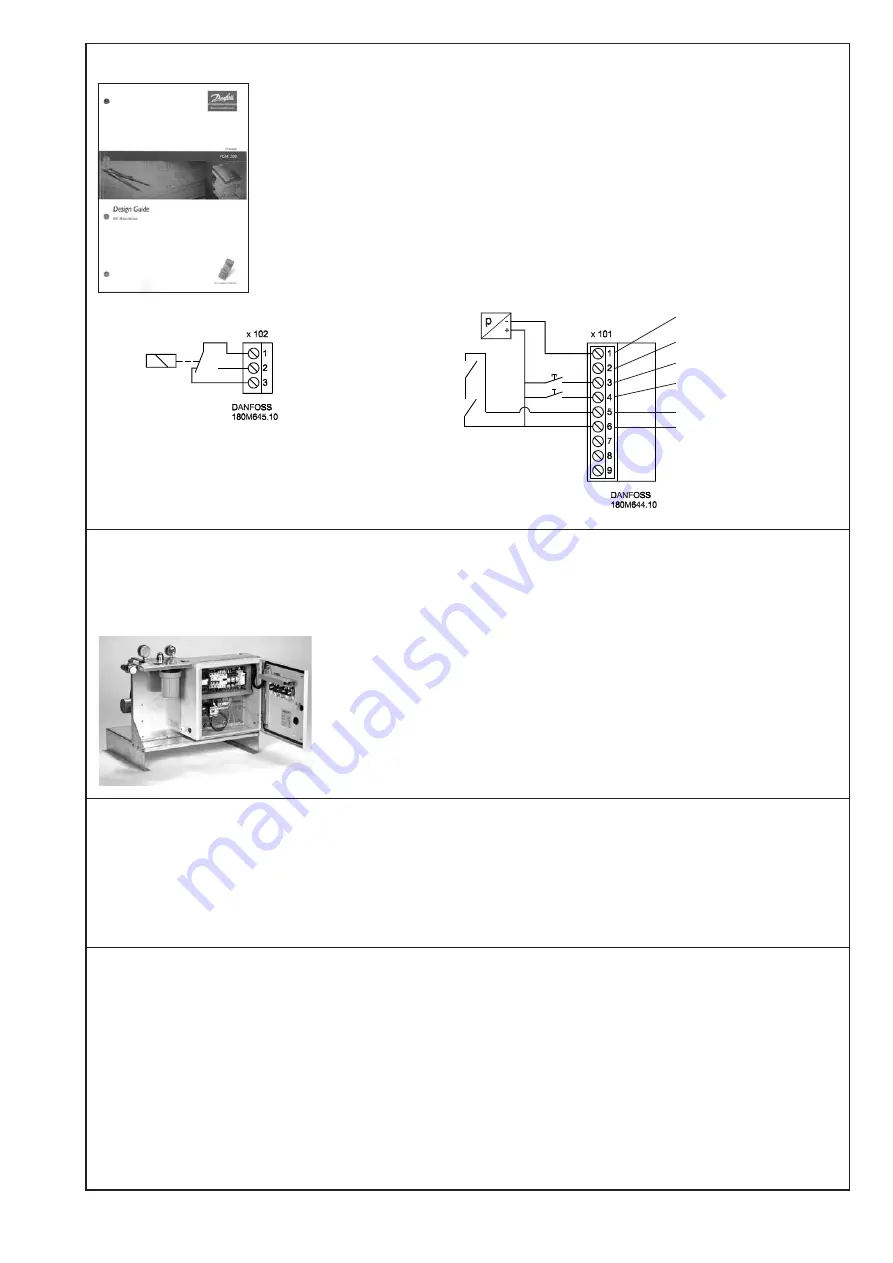

8.3 Additional wiring of the FCM 300 drive motor

The FCM 300 drive motor provides numerous possibilities for addi-

tional connections to the control system. As minimum the following

connections are recommended:

• Start/Stop

Terminal 4

• Reset (push button)

Terminal 3

• Fault indication

Relay X 102

The low-pressure switch and the high-temperature switch are

integrated in the safety loop of the FCM 300 from factory (please see

diagram).

• Motor coast, inverse

Terminal 5

Please refer to the FCM 300 instructions for detailed information.

8.4 Units with electrical connecting box

Constant speed version (CS)

Plug&Spray

TM

units equipped with electrical connecting box from fac-

tory are fully wired and prepared for direct power supply connection.

The following connections must be made:

• 3-phase power supply (3

×

400 V)

• Start-signal through external potential-free contact

• Fault relay

Please refer to the wiring diagram delivered with the system.

8.5 Units with electrical connecting box

Variable speed version (VS)

Plug&Spray

TM

units equipped with electrical connecting box from fac-

tory are fully wired and prepared for direct power supply connection.

The operator’s control is placed in the front panel of the drive motor

connecting box. The following connections must be made:

• 3-phase power supply (3

×

400 V)

• Start-signal through external potential-free contact

• Fault relay

Please refer to the wiring diagram and the manual delivered with the

FCM 300 drive motor.

Fault relay

Pressure transmitter

Temperature switch

Pressure switch

Feedback

No operation

Reset

Start

Motor coast inverse

24 V DC/25 mA supply