10

User

Guide RS8GD602 © Danfoss 2015-10

Optyma

Plus

TM

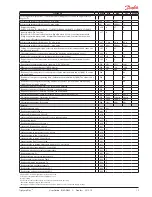

Number of LP alarms

The number of LP alarms can be read out here.

(The displayed value can be adjusted if required)

P52

LP Alarm Cnt

Number of discharge alarms

The number of Td alarms can be read out here.

(The displayed value can be adjusted if required)

P53

DisAlarm Cnt

Oil return management Speed limit

If the compressor speed exceeds this limit, a time counter will be increased. It will be

decreased if the compressor speed falls down below this limit.

P77

ORM SpeedLim

Oil return management time

Limit value of the above described time counter. If the counter exceeds this limit, the

compressor speed will be raised to the Boost speed

P78

ORM Time

Oil return management Boost speed

This compressor speed ensures that the oil returns to the compressor

P79

ORM BoostSpd

Oil return management Boost time.

The time the compressor must operate at Boost speed.

P80

ORM BoostTim

Service

Service

Read pressure Pc

u01

Pc bar

Read temperature Taux

u03

T_aux

Status on DI1 input. On/1=closed

u10

DI1 status

Status on night operation (on or off) on =night operation

u13

NightCond

Read Superheat

u21

Superheat SH

Read temperature at S6 sensor

u36

S6 temp

Read the compressor capacity in %

u52

CompCap %

Status on DI2 input. On/1=closed

u37

DI2 status

Status on relay for compressor

u58

Comp Relay

Status on relay for fan

u59

Fan relay

Status on relay for alarm

u62

Alarm relay

Status on relay "Aux"

u63

Aux Relay

Status on relay for heating element in crankcase

u71

CCH Relay

Status on input DI3 (on/1 = 230 V)

u87

DI3 status

Read condensing pressure in temperature

U22

Tc

Read pressure Ps

U23

Ps

Read suction pressure in temperature

U24

Ts

Read ambient temperature Tamb

U25

T_ambient

Read discharge temperature Td

U26

T_Discharge

Read suction gas temperature at Ts

U27

T_Suction

Voltage on the analogue output AO1

U44

AO_1 Volt

Voltage on the analogue output AO2

U56

AO_2 Volt