14

User

Guide RS8GD602 © Danfoss 2015-10

Optyma

Plus

TM

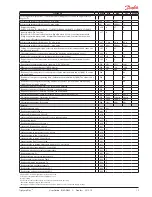

Max. condensing temperature (highest permitted Tc reference)

r83

0°C

50°C

40°C

Max. discharge gas temperature Td

r84

50°C

160°C

135°C

Alarms

Alarm time delay on signal on the DI2 input

A28

0 min.

240 min.

30 min.

Alarm for insufficient cooling in condenser. Set temperature difference.

A70

3.0 K

20.0 K

10.0 K

Delay time for A70 alarm

A71

5 min.

240 min.

30 min.

Compressor

Min. ON-time

c01

5 s

240 s

5 s

Min. OFF-time

c02

3 s

240 s

30 s

Min. time between compressor starts

c07

0 min.

30 min.

5 min.

Pump down limit at which the compressor is stopped (setting 0.0 = no function)

C33

0,0 bar

15,0 bar

0,0 bar

Min. compressor speed

c46

25 Hz

70 Hz

30 Hz

Start speed for compressor

c47

30 Hz

70 Hz

50 Hz

Max. compressor speed

c48

50 Hz

100 Hz

100 Hz

Max. compressor speed during night operation (%-value of c48)

c69

50%

100%

70%

Definition of compressor control: 0=no external start/stop; 1=switch on DI1 must start/stop

; 2=inverter compressor speed control

c71

0

2

1

Time delay for high Td. The compressor will stop when time expires.

c72

0 min.

20 min.

3 min.

Max. pressure. Compressor stops if a higher pressure is recorded

c73

7.0 bar

50.0 bar

23.0 bar

Difference for max. pressure (c73)

c74

1.0 bar

10.0 bar

3.0 bar

Min. suction pressure Ps. Compressor stops if a lower pressure is recorded

c75

-0.3 bar

10.0 bar

3.0 bar

Difference for min. suction pressure and pump down

c76

0.1 bar

5.0 bar

0.7 bar

Amplification factor Kp for compressors PI-regulation

c82

3,0

30,0

20,0

Integration time Tn for compressors PI-regulation

c83

30 s

360 s

60 s

Liquid Injection Offset

c88

0.1 K

20.0 K

5.0 K

Liquid Injection hysterese

c89

10.0 K

30.0 K

15.0 K

Compressor stop delay after Liquid injection

c90

0 s

10 s

3 s

Desired compressor speed if the signal from the pressure transmitter Ps fails

c93

25 Hz

70 Hz

60 Hz

Min On time during Low Ambient LP

c94

0

0

120

Measured Tc for which the Comp min speed is raised to StartSpeed

c95

40,0

10,0

70,0

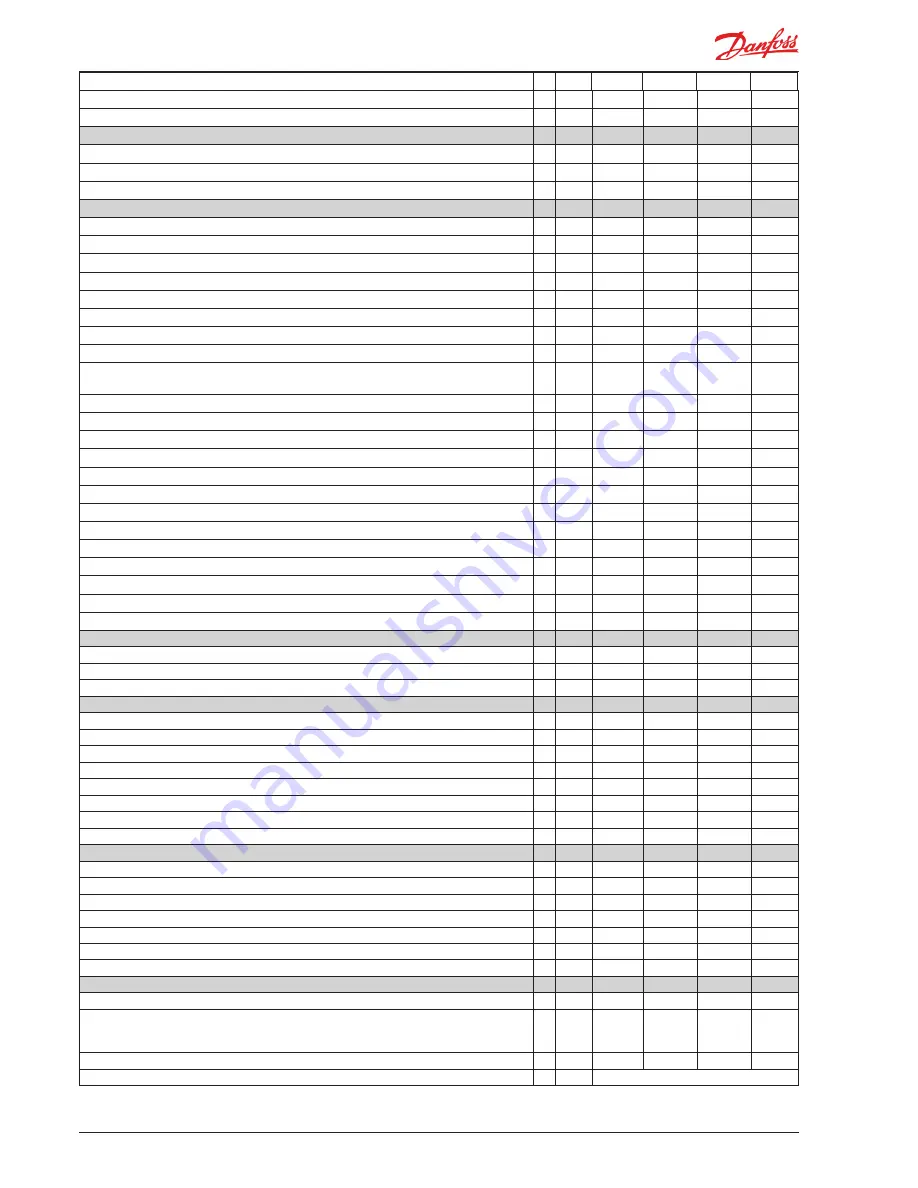

Control parameters

Amplification factor Kp for PI-regulation

n04

1.0

20.0

7.0

Integration time Tn for PI-regulation

n05

20

120

40

Kp max for PI regulation when the measurement is far from reference

n95

5,0

50,0

20,0

Fan

Readout of fan speed in %

F07

-

-

-

Permitted change in fan speed (to a lower value) % per second.

F14

1,0%

5,0%

1,0%

Jog speed (speed as a % when the fan is started)

F15

10%

100%

40%

Jog speed at low temperature

F16

0%

40%

10%

Definition of fan control: 0=Off; 1=Internal control. 2=External speed control

F17

0

2

1

Minimum fan speed. Decreased need will stop the fan.

F18

0%

40%

10%

Maximum fan speed

F19

40%

100%

100%

Manual control of the fan's speed. (Only when r12 is set to -1)

F20

0%

100%

0%

Real time clock

Time at which they switch to day operation

t17

0 hrs

23 hrs

0

Time at which they switch to night operation

t18

0 hrs

23 hrs

0

Clock - Setting of hours

t07

0 hrs

23 hrs

0

Clock - Setting of minute

t08

0 min.

59 min.

0

Clock - Setting of date

t45

1 day

31 day

1

Clock - Setting of month

t46

1 mon.

12 mon.

1

Clock - Setting of year

t47

0 year

99 year

0

Miscellaneous

Network address

o03

0

240

0

On/Off switch (Service Pin message)

IMPORTANT! o61

must

be set prior to o04

(used at LON 485 only)

o04

0/Off

1/On

0/Off

Access code (access to all settings)

o05

0

100

0

Readout of controllers software version

o08

continued

Code

Min.

Max.

Fac.

Actual