FRCC.PC.017.A1.02

6

A

PPLICATION

GUIDELINES

T

ECHNICAL

SPECIFICATIONS

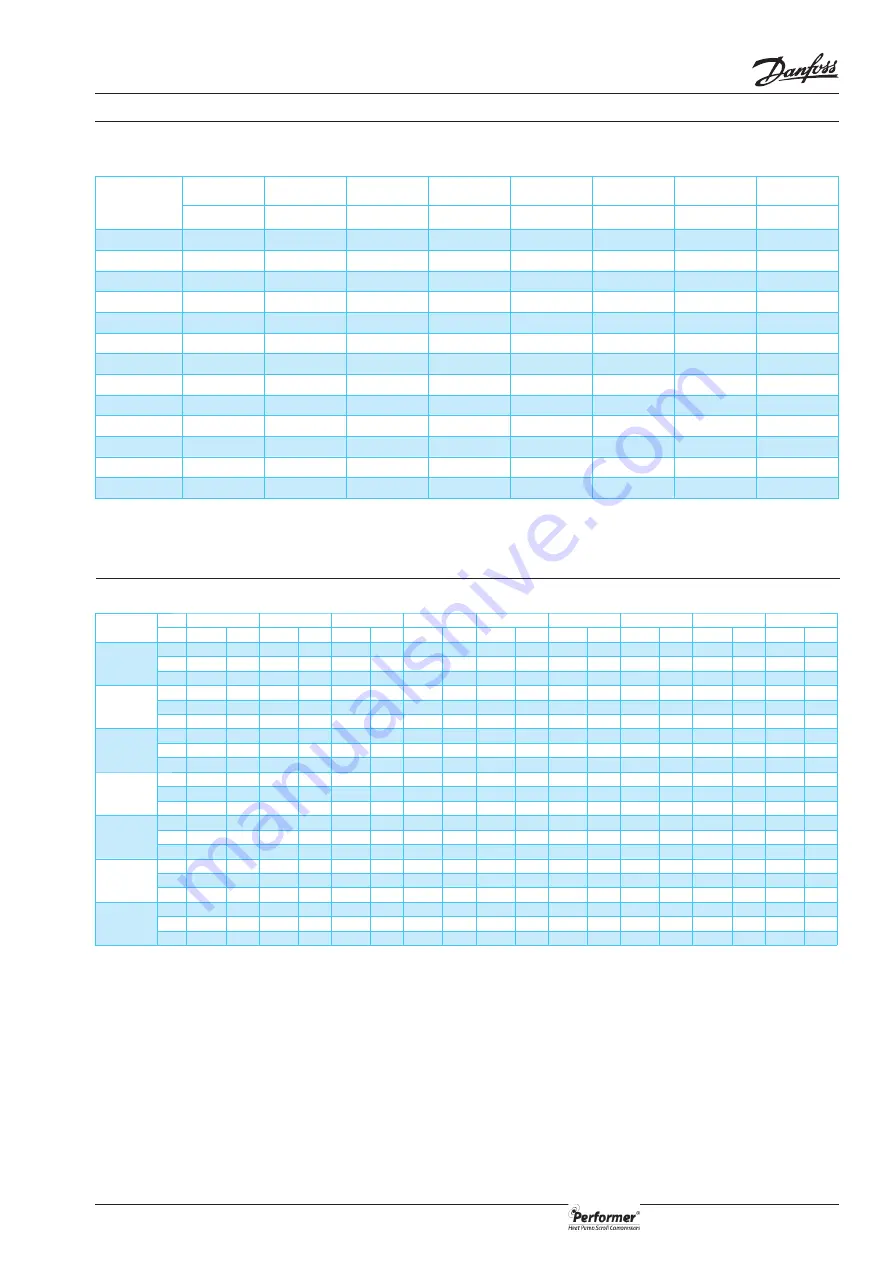

Performance table

50-Hz data

Model

Heating

capacity

Power input

Max. A.

Heating

effi

ciency

Swept volume

Displacement

Oil charge

Net weight

W

W

A

COP W/W

(cm

3

/rev)

m

3

/hr @2900

rpm

L

kg

HHP015T4LP6

4800

1540

5.1

3.13

34

5.9

1.06

31

HHP015T5LP6

4880

1660

14.2

2.93

34

5.9

1.06

30

HHP019T4LP6

5780

1910

5.8

3.02

41

7.1

1.06

31

HHP019T5LP6

5830

2040

17.7

2.86

41

7.1

1.06

31

HHP021T4LP6

6410

2030

5.8

3.16

46

8

1.06

31

HHP021T5LP6

6630

2110

18.2

3.15

46

8

1.06

31

HHP026T4LP6

8100

2520

7.1

3.22

57

10

1.06

31

HHP026T5LP6

8160

2680

22.7

3.04

57

10

1.06

31

HHP030T4LC6

9700

3070

8.6

3.17

67

11.7

1.57

37

HHP030T5LC6

9790

3190

27.7

3.07

67

11.7

1.57

41

HHP038T4LC6

12050

3730

10.8

3.23

82

14.2

1.57

39

HHP038T5LC6

12140

3850

35.2

3.16

82

14.2

1.57

41

HHP045T4LC6

13940

4300

12.6

3.25

99

17.2

1.57

40

Evaporating temperature: -7° C

Condensing temperature: 50°C

Superheat: 10 K

Subcooling: 5 K

Subject to modifi cation without prior notifi cation

Conditions: 400V/3ph/50Hz (motor T4), 230V/1ph/50 Hz (motor T5)

For full data details and capacity tables refer to Online Datasheet Generator : www.danfoss.com/odsg

Model

To

-25

-20

-15

-10

-5

0

5

10

15

Tc

H

Pe

H

Pe

H

Pe

H

Pe

H

Pe

H

Pe

H

Pe

H

Pe

H

Pe

HHP015T4

40

2 550

1.1

3 070

1.1

3 720

1.2

4 510

1.3

5 450

1.3

6 520

1.4

7 730

1.4

9 080

1.4

10 570

1.4

50

2 620

1.5

3 050

1.5

3 620

1.5

4 320

1.5

5 150

1.6

6 120

1.6

7 220

1.7

8 460

1.7

9 840

1.7

60

-

-

-

-

3 860

2.2

4 410

2.1

5 090

2.1

5 890

2.1

6 830

2.1

7 900

2.1

9 100

2.1

HHP019T4

40

3 070

1.3

3 680

1.4

4 450

1.5

5 400

1.5

6 520

1.6

7 810

1.7

9 270

1.7

10 900

1.7

12 690

1.7

50

3 180

1.7

3 680

1.7

4 340

1.8

5 180

1.9

6 180

1.9

7 340

2.0

8 670

2.1

10 160

2.2

11 830

2.2

60

-

-

-

-

4 660

2.3

5 300

2.4

6 110

2.4

7 070

2.5

8 200

2.6

9 480

2.7

10 930

2.8

HHP021T4

40

3 530

1.4

4 250

1.5

5 090

1.6

6 080

1.7

7 230

1.7

8 570

1.8

10 100

1.8

11 840

1.7

13 820

1.7

50

3 430

1.6

4 080

1.8

4 860

1.9

5 770

2.0

6 830

2.1

8 070

2.1

9 500

2.2

11 140

2.2

13 000

2.2

60

-

-

-

-

4 710

2.2

5 530

2.3

6 510

2.5

7 650

2.6

8 970

2.7

10 490

2.8

12 240

2.8

HHP026T4

40

4 540

1.7

5 410

1.9

6 440

2.0

7 650

2.1

9 070

2.1

10 740

2.2

12 690

2.2

14 950

2.1

17 550

2.0

50

4 590

2.0

5 350

2.1

6 260

2.3

7 330

2.4

8 610

2.6

10 120

2.6

11 900

2.7

13 970

2.7

16 370

2.7

60

-

-

-

-

6 240

2.7

7 150

2.9

8 250

3.0

9 560

3.2

11 130

3.3

12 980

3.3

15 150

3.3

HHP030T4

40

4 910

2.1

6 100

2.3

7 480

2.4

9 050

2.6

10 830

2.6

12 830

2.7

15 060

2.7

17 520

2.8

20 240

2.9

50

4 830

2.3

5 940

2.6

7 230

2.8

8 690

3.0

10 350

3.1

12 200

3.2

14 270

3.4

16 560

3.5

19 090

3.6

60

-

-

-

-

7 000

3.1

8 330

3.4

9 850

3.6

11 550

3.8

13 440

4.0

15 540

4.2

17 870

4.4

HHP038T4

40

6 150

2.4

7 600

2.8

9 360

3.0

11 390

3.2

13 660

3.2

16 130

3.3

18 750

3.3

21 510

3.4

24 360

3.6

50

5 730

2.2

7 120

2.8

8 800

3.3

10 740

3.6

12 890

3.8

15 220

4.0

17 700

4.1

20 280

4.2

22 940

4.4

60

-

-

-

-

8 090

3.2

9 930

3.8

11 970

4.2

14 170

4.5

16 500

4.7

18 920

5.0

21 400

5.2

HHP045T4

40

7 110

3.0

8 800

3.1

10 830

3.3

13 180

3.5

15 800

3.7

18 660

3.8

21 700

3.9

24 890

3.8

28 180

3.7

50

6 630

3.5

8 240

3.7

10 190

3.9

12 420

4.2

14 910

4.4

17 610

4.6

20 480

4.7

23 460

4.8

26 540

4.8

60

-

-

-

-

9 360

4.5

11 490

4.8

13 850

5.1

16 400

5.5

19 100

5.7

21 890

6.0

24 760

6.1

Legend

:

To: Evaporating temperature in °C

H: Heating capacity in W

Superheat = 5 K

Tc: Condensing temperature in °C

Pe: Power input in kW

Subcooling = 5 K