Application guidelines

17

FRCC.PC.021.A5.22

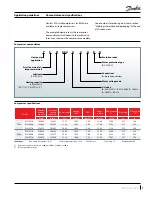

Electrical data, connections and wiring

Six different knockouts are available for power

supply or accessories connections.

One double knockout for power supply:

Ø1.72" (43.7mm ) or Ø1.36" (34.5mm)

One triple knockout for power supply:

Ø1.59" (40.5mm) or Ø1.27" (32.5mm) or

Ø1" (25.4mm)

Two double knockouts for accessories:

Ø1" (25.4mm) or Ø0.78" (20mm)

Two double knockouts for accessories:

Ø0.88" (22.5mm) or Ø0.65" (16.5mm)

Electrical box knock-out

dimensions

The temperature inside the terminal box must

not exceed 149°F. Above 149°F, the OCS may

not operate properly. Any compressor damaged

related to this will not be covered by Danfoss

warranty.

Consequently, if the compressor is installed in an

enclosure, precautions must be taken to avoid

that the temperature around the compressor and

in the terminal box rise too much. The installation

of ventilation on the enclosure panels may be

necessary.

In the same manner, cables must be selected in a

way to insure that terminal box temperature does

not exceed 149°F.

Electrical box temperature

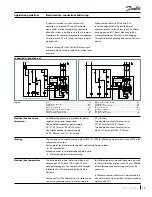

Suggested wiring diagram

Legend

Fuses ...........................................................................................................F1

Compressor contactor ........................................................................ KM

Control relay ............................................................................................ KA

Safety lock out relay ..............................................................................KS

Optional short cycle timer (3 min) ............................................. 180 s

External overload protection .............................................................F2

Pump-down pressure switch .............................................................LP

High pressure safety switch ...............................................................HP

Control device ........................................................................................ TH

Liquid line solenoid valve ............................................................... LLSV

Fused disconnect ..................................................................................Q1

Compressor motor ..................................................................................M

Thermistor chain ....................................................................................... S

Safety pressure switch ........................................................................LPS

A1

A3

A2

LP

LPS

M

S

OCS

Wiring diagram with pump-down cycle

M1 M2

A1

A3

A2

OCS

S

KS

LPS

Control circuit

Wiring diagram without pump down cycle

M1 M2

The compressor terminal box according to IEC529 is IP54 for all models when correctly sized IP54 rated

cable glands are used.

First numeral, level of protection against contact and foreign objects

5

- Dust protected

Second numeral, level of protection against water

4

- Protection against water splashing

IP rating

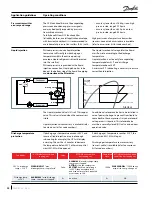

In specific situations, such as winter start

operation, an eventual LP control for pump-

down cycles may be temporarily bypassed to

allow the system to build pressure. But it remains

mandatory for compressor protection to apply an

LP safety switch. The LP safety switch must never

be bypassed.

Pressure settings for the LP and HP safety switch

and pump-down listed in table from section “Low

pressure”.

When ever possible (ie. PLC control), it is

recommended to limit the possibilities of

compressor auto restart to less than 3 to 5 times

during a period of 12 hours when caused by

motor protection or LP safety switch tripping.

This control must be managed as a manual reset

device.