Application guidelines

20

FRCC.PC.021.A5.22

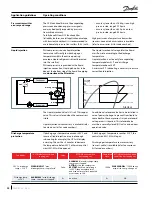

Operating conditions

2 status LEDs are present on OCS:

LED 2 displays the motor protection status.

Compressor models PSH051-064-077 are

delivered with a pre installed motor protection.

This device provides efficient and reliable

protection against overheating, overloading as

well as phase loss/reversal.

The motor protection is effective thanks to PTC

sensors embedded in the motor winding and

OCS control. The close contact between sensors

and windings ensures a very low level of thermal

inertia.

The motor temperature is constantly measured

by a PTC thermistor loop connected to the OCS.

If any thermistor exceeds its response

temperature, its resistance increases above the

trip level (4,500 Ω) and the output relay then trips

– i.e. contacts M1-M2 are open.

After cooling below the response temperature

(resistance < 2,750 Ω), a 5 minutes time delay is

activated. After this delay has elapsed, the relay

is once again pulled in – i.e. contacts M1-M2

are closed. The time delay may be cancelled by

means of resetting the mains.

Compressor protection

Overheating/overloading

protection

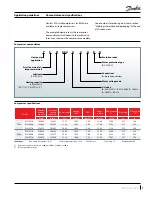

LED1 (red) displays the

board general status

LED2 (yellow) displays the

motor protection status

LED1 displays the board general status with the following blinking codes

LED 2 Status display

Blinking sequence

Status

continuous on

Ready for starting

0.1secON/ 0.3secOFF

for 5 min 0.1secON/0,7secOFF.

ALARM 22

: Motor overheating

ACTION

: STOP COMPRESSOR

RESTART

: 5min Delay after motor cooling.

LED 1 Status display

Blinking sequence

Status

Reset

continuous on

OCS powered and stable

NA

slow blinking

1.5secON/1secOFF

Warning without requirement

for immediate action.

Come back to stable status

by automatic or manual reset.

fast blinking

0.5secON/0.5secOFF

ALARM

, requires

maintenance intervention

Come back to stable status

by specialist intervention