Application guidelines

21

FRCC.PC.021.A5.22

Operating conditions

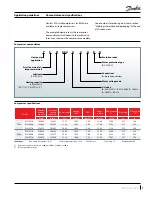

Application envelope

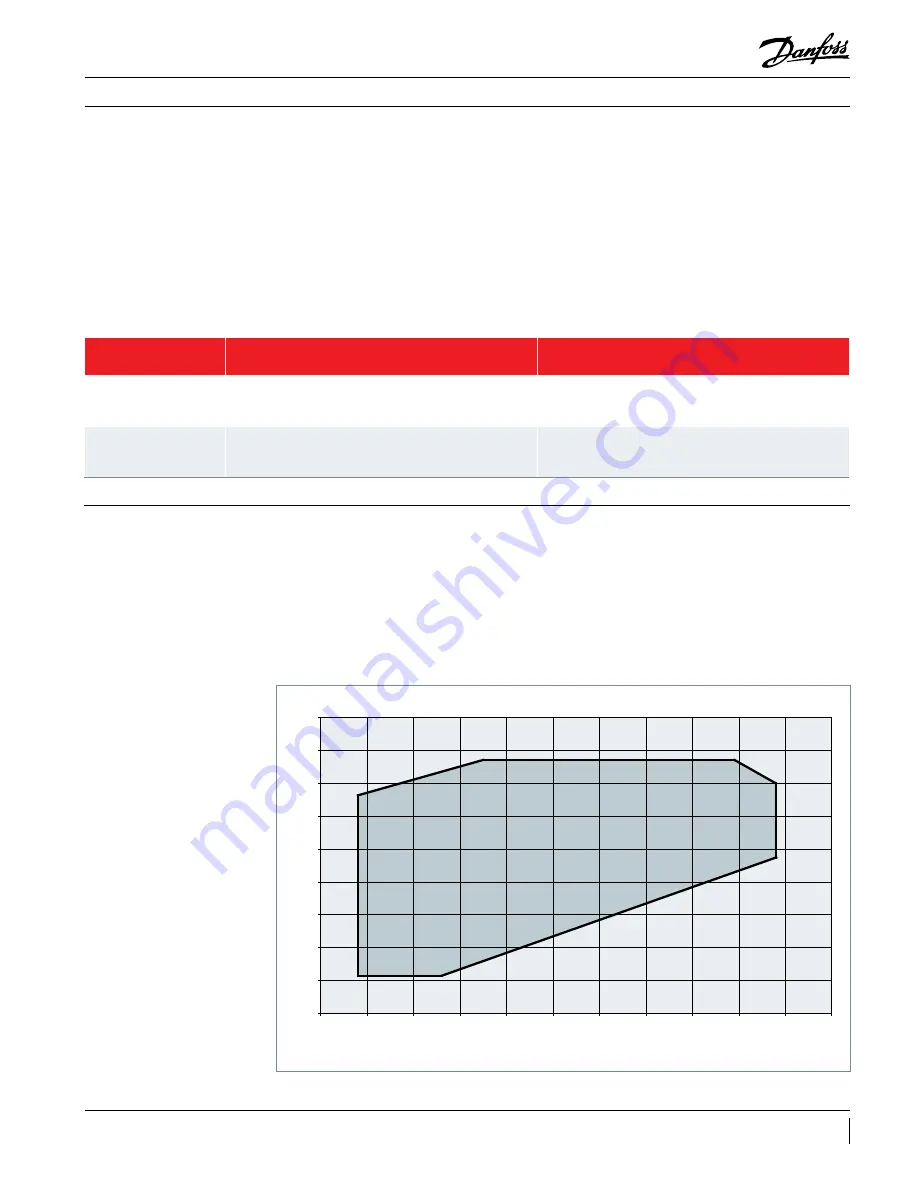

The operating envelope for PSH scroll

compressors is given in the figure below, where

the condensing and evaporating temperatures

represent the range for steady-state operation.

The operating limits serve to define the

envelope within which reliable operations of the

compressor are guaranteed:

• Maximum discharge gas temperature: 284°F

(measured by DGT sensor),

• A suction superheat below 9°F is not allowed

due to the risk of liquid flood back,

• Maximum suction superheat of 36°F

• A subcooling above 9°F is recommended to

ensure proper liquid injection.

• Minimum and maximum evaporating and

condensing temperatures as per the opera-

ting envelopes.

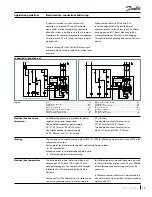

Use a phase meter to establish the phase

orders and connect line phases L1, L2 and L3

to terminals T1, T2 and T3, respectively. The

compressor will only operate properly in a single

direction, and the motor is wound so that if the

connections are correct, the rotation will also be

correct.

OCS provides protection against phase reversal

and phase loss at start-up.

Apply the recommended wiring diagrams from

the section “Suggested wiring diagram logic”. The

circuit should be thoroughly checked in order to

determine the cause of the phase problem before

re-energizing the control circuit.

The phase sequencing and phase loss monitoring

functions are active during a 5 seconds window

1 second after compressor start-up (power on

L1-L2-L3)

Phase sequence and reverse

rotation protection

LED 2 Status display

Blinking sequence

Status

0.2secON/0.2secOFF

0.2secON/0.4secOFF

ALARM 25

:Phase reverse error

ACTION

: STOP COMPRESSOR

RESTART

: Come back to stable status by manual reset

0.5secON/0.5secOFF

ALARM 24

:Phase loss error

ACTION

: STOP COMPRESSOR

RESTART

: Come back to stable status by manual reset

0

20

40

60

80

100

120

140

160

180

-30

-20

-10

0

10

20

30

40

50

60

70

80

Evap. Temp. °F

Co

nd

. T

em

p.

°F