Application guidelines

25

FRCC.PC.021.A5.22

Operating conditions

The OCS will display alarms when the compressor

is running outside the operating envelope. The

compressor will be stopped when it does not

come back to normal running conditions within a

defined delay.

High and low pressure

protection

The OCS also provides information about below

listed malfunctions.

Maintenance operations should include an OCS

diagnosis analysis, in order to check the warnings

and alarms status history provided by the OCS.

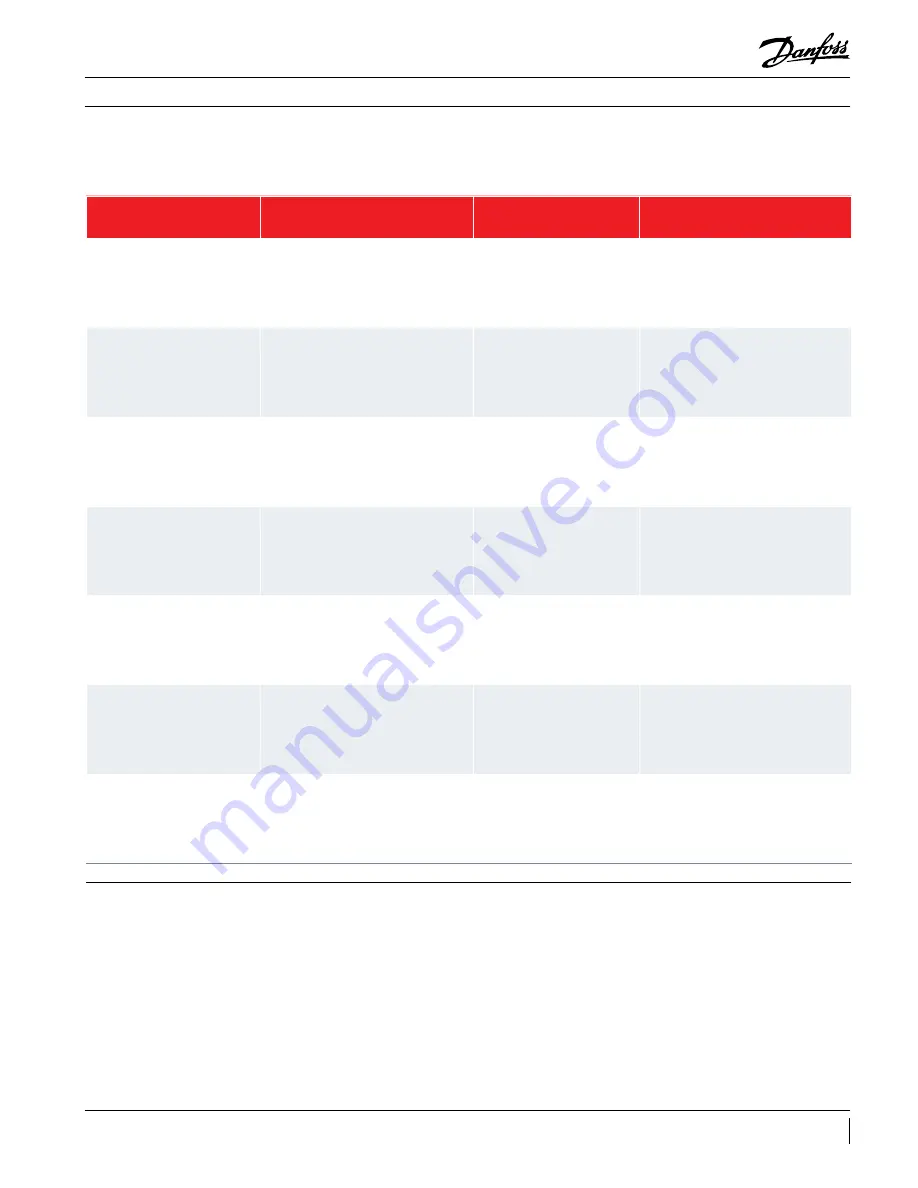

Malfunction protection

Component

Detection Criteria(s)

Alarm

Action

Crankcase heater

Resistance out of operating range

OR

Current out of range

WARNING W43

: “Crankcase

heater dysfunction”.

No action

Discharge Temperature sensor

(1 on each compressor)

Resistance out of operating temperature

range

ALARM A42

: “Discharge

Temperature sensor error”

STOP the compressor

Pressure transducers LP

(1 on compressor OR via comm.

bus)

Voltage out of sensor operating pressure

range [0,1;4,9]V

OR

broadcasting not available via CAN-Bus

ALARM A15

: “Low Pressure

transmitter error”.

Auto search for alternative sensor on the

manifold,

else

STOP the compressor.

RESTART sequence

value back to normal range, then

automatic reset.

Pressure transducers HP

(1 on compressor OR via comm.

bus)

Voltage out of sensor operating pressure

range [0,1;4,9]V

OR

broadcasting not available via CAN-Bus

ALARM A16

: “High Pressure

transmitter error”.

Auto search for alternative sensor on the

manifold,

else

STOP the compressor.

RESTART sequence

value back to normal range, then

automatic reset.

Motor PTC

Resistance out of operating range

ALARM A20

: “PTC is open”.

STOP the compressor (open Switch).

RESTART sequence

value back to normal range, then

automatic reset.

CAN-Bus

Compressor1

Compressor2

or Mainboard

Timeout 10s

WARNING W21

:

“Communication bus disabled” No action

Modbus bus

Compressor1

MAINBOARD

Timeout 1min

WARNING W21

:

“Communication bus disabled” No action