Application guidelines

49

FRCC.PC.021.A5.22

Installation

Filter driers

Refrigerant charging

Refrigerant charge limit

A properly sized & type of drier is required.

Important selection criteria include the driers

water content capacity, the system refrigeration

capacity and the system refrigerant charge.

The drier must be able to reach and maintain

a moisture level of 50 ppm end point dryness

(EPD).

For new installations with PSH compressors with

polyolester oil, Danfoss recommends using the

Danfoss DML (100% molecular sieve) solid core

filter drier. Molecular sieve filter driers with loose

beads from third party suppliers shall be avoided.

For servicing of existing installations where acid

formation is present the Danfoss DCL (solid core)

filter driers containing activated alumina are

recommended.

The drier is to be oversized rather than under

sized. When selecting a drier, always take into

account its capacity (water content capacity),

the system refrigeration capacity and the system

refrigerant charge.

After burn out, remove & replace the liquid line

filter drier and install a Danfoss type DAS burnout

drier of the appropriate capacity. Refer to the DAS

drier instructions and technical information for

correct use of the burnout drier on the liquid line.

For the initial charge the compressor must not

run and eventual service valves must be closed.

Charge refrigerant as close as possible to the

nominal system charge before starting the

compressor.

This initial charging operation must be done in

liquid phase. The best location is on the liquid

line between the condenser outlet and the

filter drier. Then during commissioning, when

needed, a complement of charge can be done

in liquid phase: slowly throttling liquid in on

the low pressure side as far away as possible

from the compressor suction connection while

compressor is running. The refrigerant charge

quantity must be suitable for both summer and

winter operations.

Vacuum or charge from one side can seal the

scrolls and result in a non-starting compressor.

When servicing, always ensure that LP/HP

pressures are balanced before starting the

compressor.

Be sure to follow all government regulations

regarding refrigerant reclamation and storage.

For more detailed information see

“Recommended refrigerant system charging

practice” news bulletin FRCC.EN.050.

Danfoss PSH compressors can tolerate liquid

refrigerant up to a certain extend without major

problems. However, excessive liquid refrigerant in

the compressor is always unfavourable for service

life. Besides, the installation cooling capacity may

be reduced because of the evaporation taking

place in the compressor and/or the suction line

instead of the evaporator. System design must be

such that the amount of liquid refrigerant in the

compressor is limited.

In this respect, follow the guidelines given

in the section:”Essential piping design

recommendations” in priority.

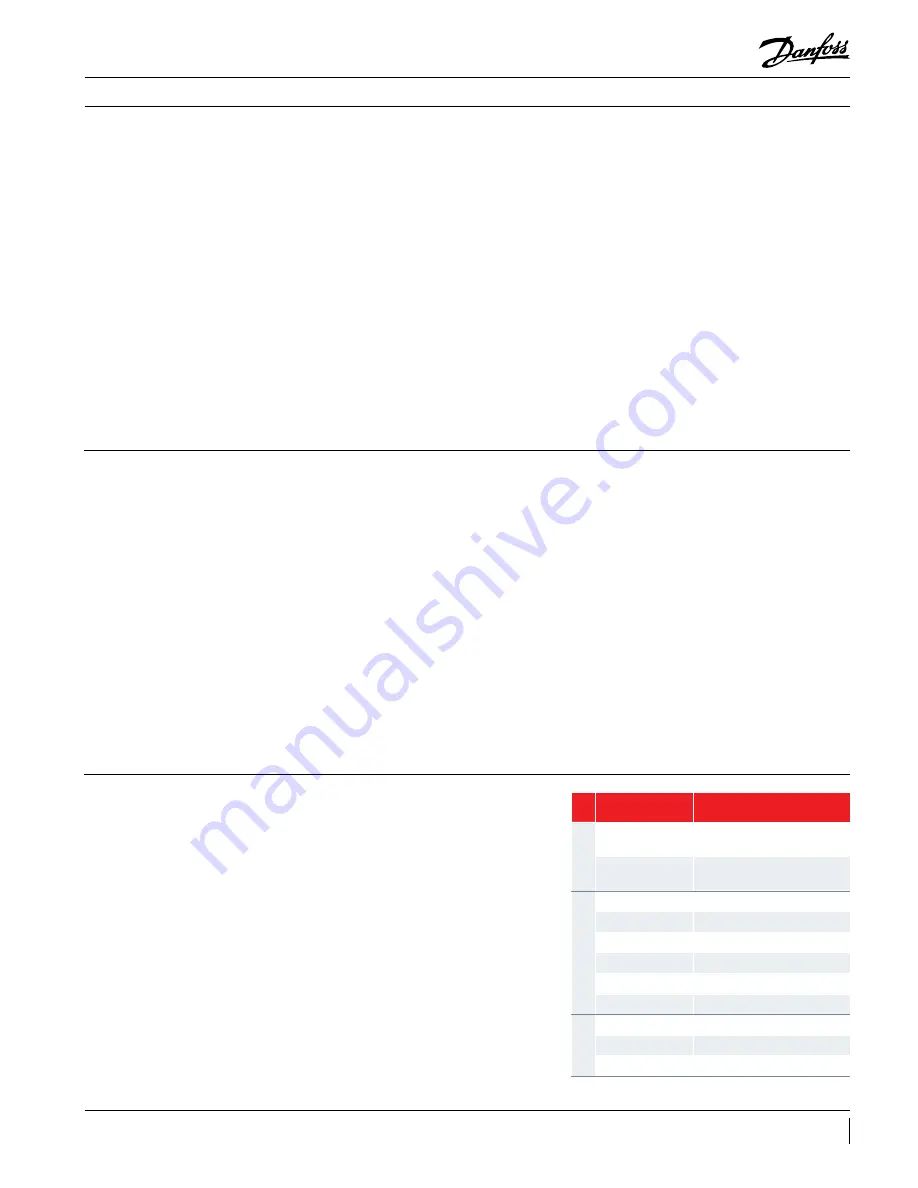

Use the tables below to quickly evaluate the

required compressor protection in relation with

the system charge and the application.

Model

Refrigerant charge limit

in the compressor (lb)

Com

pr

es

sor PSH051-064

29.8

PSH077

32

Tandem

PSH104

38.6

PSH115

38.6

PSH130

38.6

PSH128

38.6

PSH141

38.6

PSH154

38.6

Tr

io

PSH153

50.7

PSH192

50.7

PSH231

54