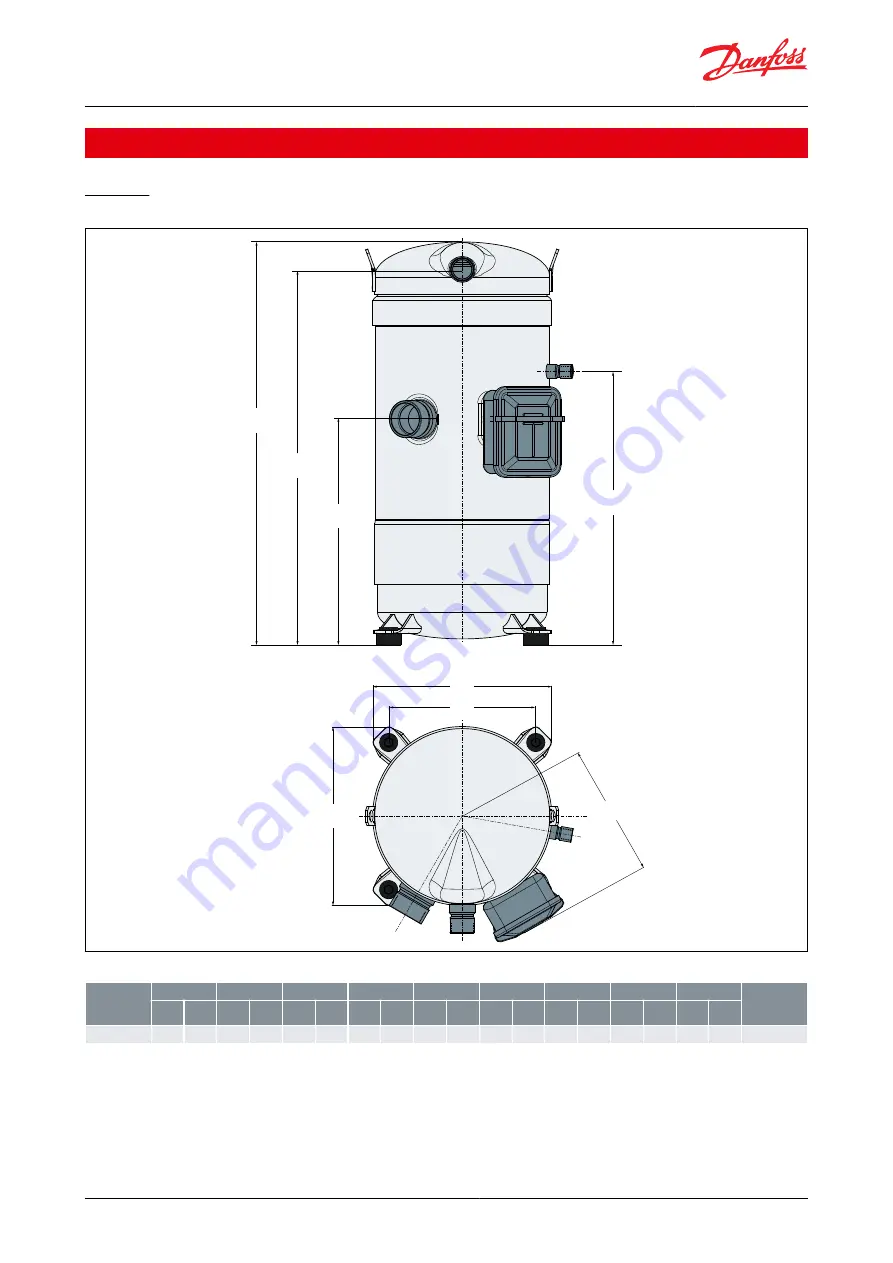

Dimensions

VCH115

Figure 5: Outline drawing

H3

H2

H1

H4

L4

L3

L1

L2

Danfoss

Di-000002

Table 5: Dimensions for VCH115

Compressor

model

D

H1

H2

H3

H4

L1

L2

L3

L4

Outline

drawing

number

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

VCH115

224.3

8.83

291.4 11.47 485.4 19.11 520.9 20.51 353.4

13.9

231

9.09

231

9.09

190.5

7.5

171.1

6.74

8560210

Also refer

and

Scroll compressors, VCH115 | Dimensions

© Danfoss | Climate Solutions | 2023.08

AB392939083370en-000202 | 14