1

2

3

4

6

5

Danf

oss

C

A-000001

1

2

3

4

5

6

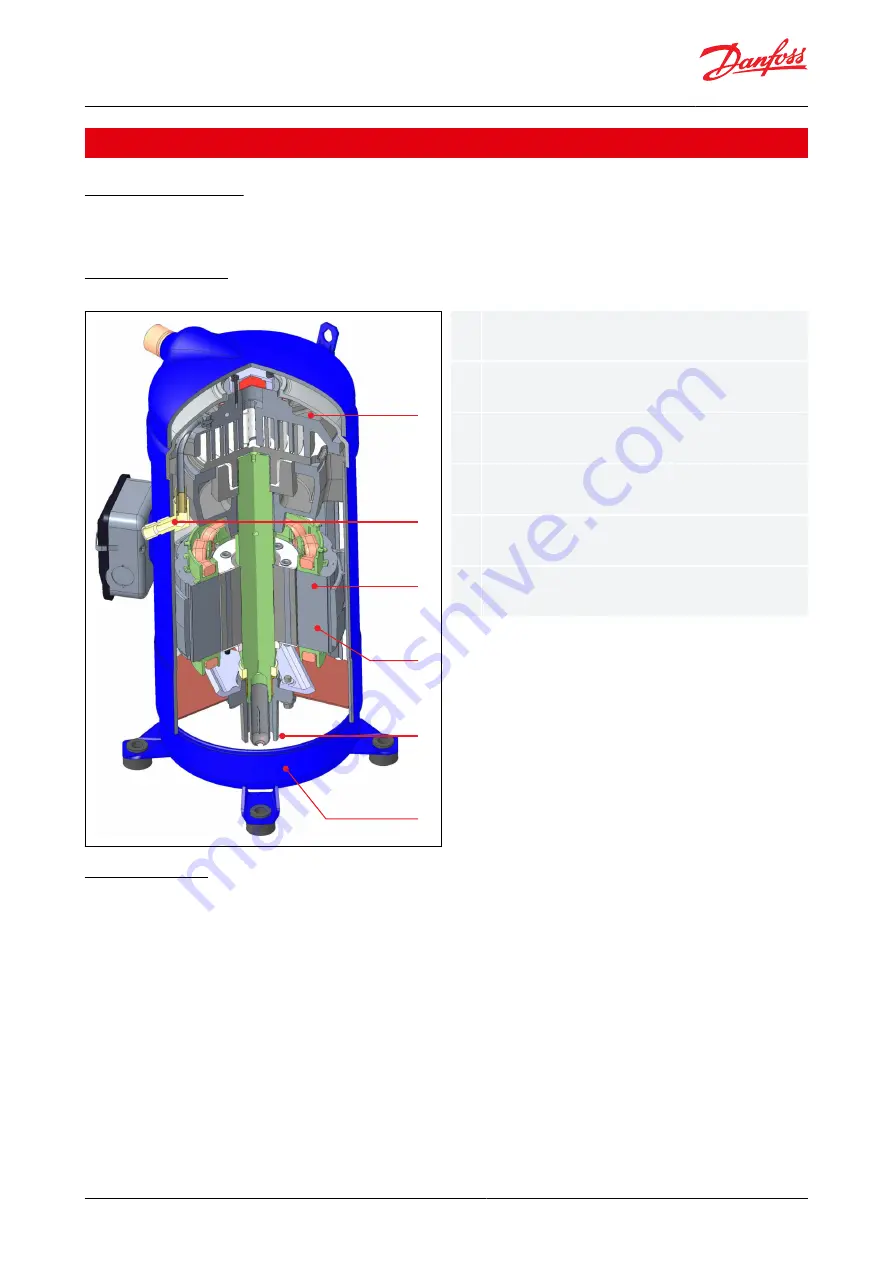

Optimize scroll sets PR, combine vapor injection,

and optimize

efficiency

in heat pump application

Increase injection pipe diameter, and reduce pipe

vibration

Optimize structure design, reduce compressor

acoustic at high speed

New designed high

efficiency

motor, improve

efficiency

at Part- load condition

Oil strainer reduce the oil stirring when

compressor running

Compact compressor outline design,

beneficial

for

system unit layout

Introduction

Product description

Danfoss scroll compressor VCH115 for R410A is optimized for China low ambient heat pump and modular chiller

application.

Cut Away VCH115

Figure 1: Cut Away VCH115

Vapor injection

The VCH115 compressor is

fitted

with an injection port that enables to carry out vapor injection by connecting an

intermediate exchanger.

This vapor injection will have three

benefits:

• Operating envelope enlargement by reduction of resulting discharge temperature.

• Cooling capacity and cooling

efficiency

improvement by reduction of the liquid temperature before expansion

(Intermediate exchanger acting as economizer).

• Heat capacity and heating

efficiency

improvement by increase of the

massflow

at the condenser side (condenser

massflow

will be the sum of the evaporator

massflow

and the injected

massflow).

The diagrams below explain the vapor injection principle, considering:

m inj:

Injected

massflow

ΔT IntX:

Difference

of temperature between the outlet of intermediate exchanger and the intermediate pressure

bubble point.

© Danfoss | Climate Solutions | 2023.08

AB392939083370en-000202 | 5

Scroll compressors, VCH115 | Introduction