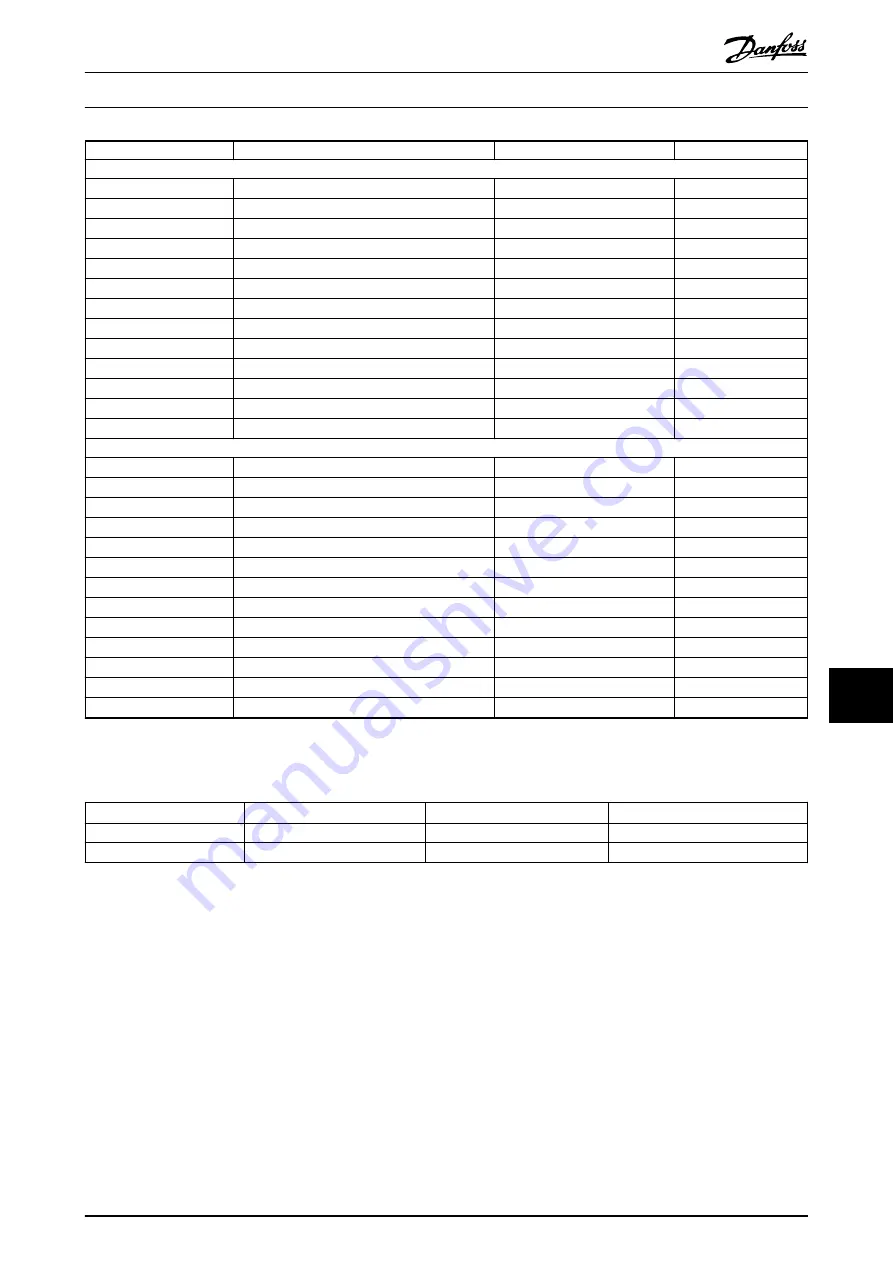

Frequency converter

Max. fuse size

Voltage

Type

200-240V

K25-K75

10A

1

200-240

gG

1K1-2K2

20A

1

200-240

gG

3K0

30A

1

200-240

gG

3K7

30A

1

200-240

gG

5K5

50A

1

200-240

gG

7K5

63A

1

200-240

gG

11K

63A

1

200-240

gG

15K

80A

1

200-240

gG

18K5

125A

1

200-240

gG

22K

125A

1

200-240

gG

30K

160A

1

200-240

gG

37K

200A

1

200-240

aR

45K

250A

1

200-240

aR

380-480V

K37-1K5

10A

1

380-480

gG

2K2-4K0

20A

1

380-480

gG

5K5-7K5

30A

1

380-480

gG

11K

63A

1

380-480

gG

15K

63A

1

380-480

gG

18K

63A

1

380-480

gG

22K

63A

1

380-480

gG

30K

80A

1

380-480

gG

37K

100A

1

380-480

gG

45K

125A

1

380-480

gG

55K

160A

1

380-480

gG

75K

250A

1

380-480

aR

90K

250A

1

380-480

aR

Table 10.9 Non UL fuses 200V to 480V

1) Max. fuses - see national/international regulations for selecting an

applicable fuse size.

Danfoss PN

Bussmann

Ferraz

Siba

20220

170M4017

6.9URD31D08A0700

20 610 32.700

20221

170M6013

6.9URD33D08A0900

20 630 32.900

Table 10.10 Additional Fuses for Non-UL Applications, E enclosures, 380-480V

Specifications

VLT

®

AQUA Drive

Operating Instructions

MG.20.M8.02 - VLT

®

is a registered Danfoss trademark

81

10

10