90

80

70

60

50

40

30

20

10

0

(%)

Dr

iv

e D

er

ating

0

25

50

75

100

125

150

175

225

130BB190.10

200

Pressure Change

Figure 3.5 F-Frame Derating vs. Pressure Change Drive Air

Flow: 580 cfm (985 m

3

/h)

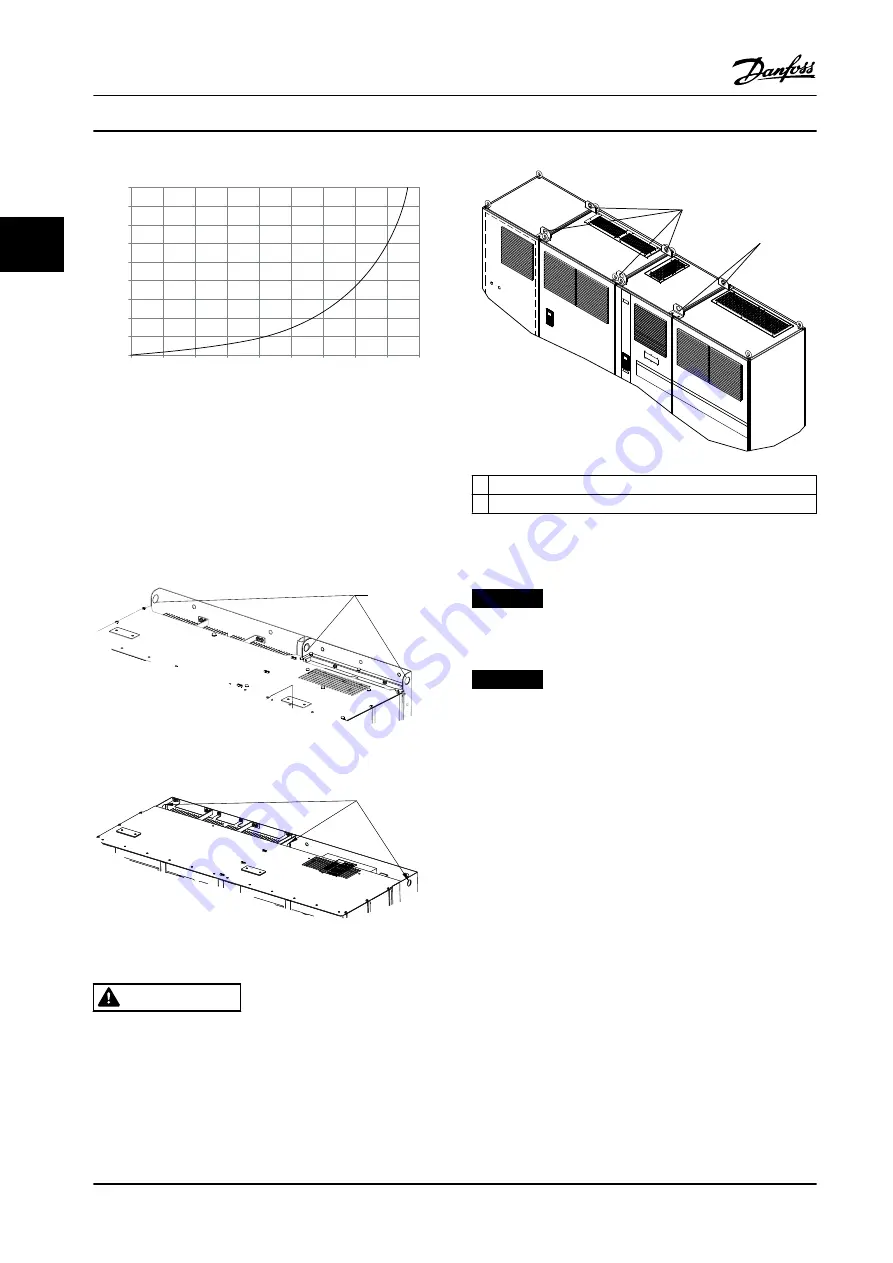

3.3.2 Lifting

Lift the adjustable frequency drive using the dedicated

lifting eyes. For all D-frames, use a bar to avoid bending

the lifting holes of the adjustable frequency drive.

Lifting Holes

130BC166.10

Figure 3.6 Recommended Lifting Method, Frame Size D13

130BC170.10

Lifting Holes

Figure 3.7 Recommended Lifting Method, Frame Size E9

WARNING

The lifting bar must be able to handle the weight of the

adjustable frequency drive. See for the weight of the

different frame sizes. Maximum diameter for bar is 1 in

[2.5 cm]. The angle from the top of the adjustable

frequency drive to the lifting cable should be 60° or

greater.

1

2

130BD574.10

1 Lifting holes for the filter

2 Lifting holes for the adjustable frequency drive

Figure 3.8 Recommended Lifting Method, Frame Size F18

NOTICE!

A spreader bar is also an acceptable way to lift the F-

frame.

NOTICE!

The F18 pedestal is packaged separately and included in

the shipment. Mount the adjustable frequency drive on

the pedestal in its final location. The pedestal allows

proper airflow and cooling.

Installation

VLT

®

AutomationDrive FC 302 Low Harmonic Drive

132–630 kW

24

Danfoss A/S © Rev. 04/2015 All rights reserved.

MG37A322

3

3