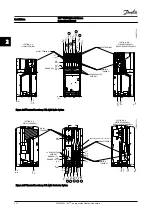

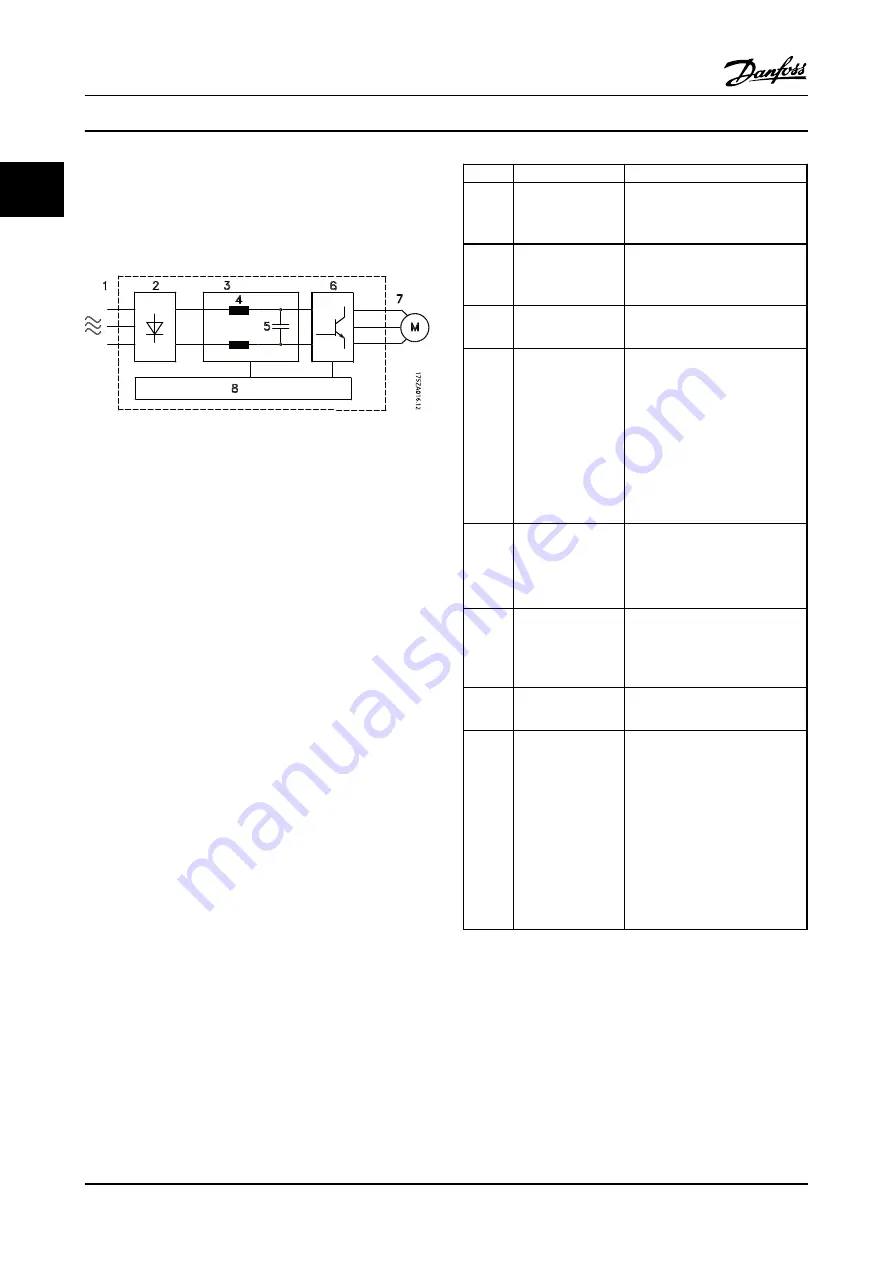

1.5 Internal Controller Functions

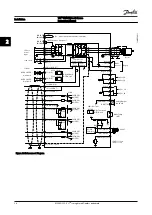

is a block diagram of the adjustable frequency

drive's internal components. See

for their

functions.

Figure 1.4 Adjustable Frequency Drive Block Diagram

Area

Title

Functions

1

Mains input

•

Three-phase AC line power

supply to the adjustable

frequency drive

2

Rectifier

•

The rectifier bridge converts

the AC input to DC current to

supply inverter power

3

DC bus

•

Intermediate DC bus circuit

handles the DC current

4

DC reactors

•

Filter the intermediate DC

circuit voltage

•

Prove line transient protection

•

Reduce RMS current

•

Raise the power factor

reflected back to the line

•

Reduce harmonics on the AC

input

5

Capacitor bank

•

Stores the DC power

•

Provides ride-through

protection for short power

losses

6

Inverter

•

Converts the DC into a

controlled PWM AC waveform

for a controlled variable

output to the motor

7

Output to motor

•

Regulated three-phase output

power to the motor

8

Control circuitry

•

Input power, internal

processing, output, and motor

current are monitored to

provide efficient operation

and control

•

User interface and external

commands are monitored and

performed

•

Status output and control can

be provided

Table 1.3 Adjustable Frequency Drive Internal Components

Introduction

VLT

®

HVAC Drive D-Frame

Instruction Manual

1-4

MG16D222 - VLT

®

is a registered Danfoss trademark

1

1