•

•

•

-

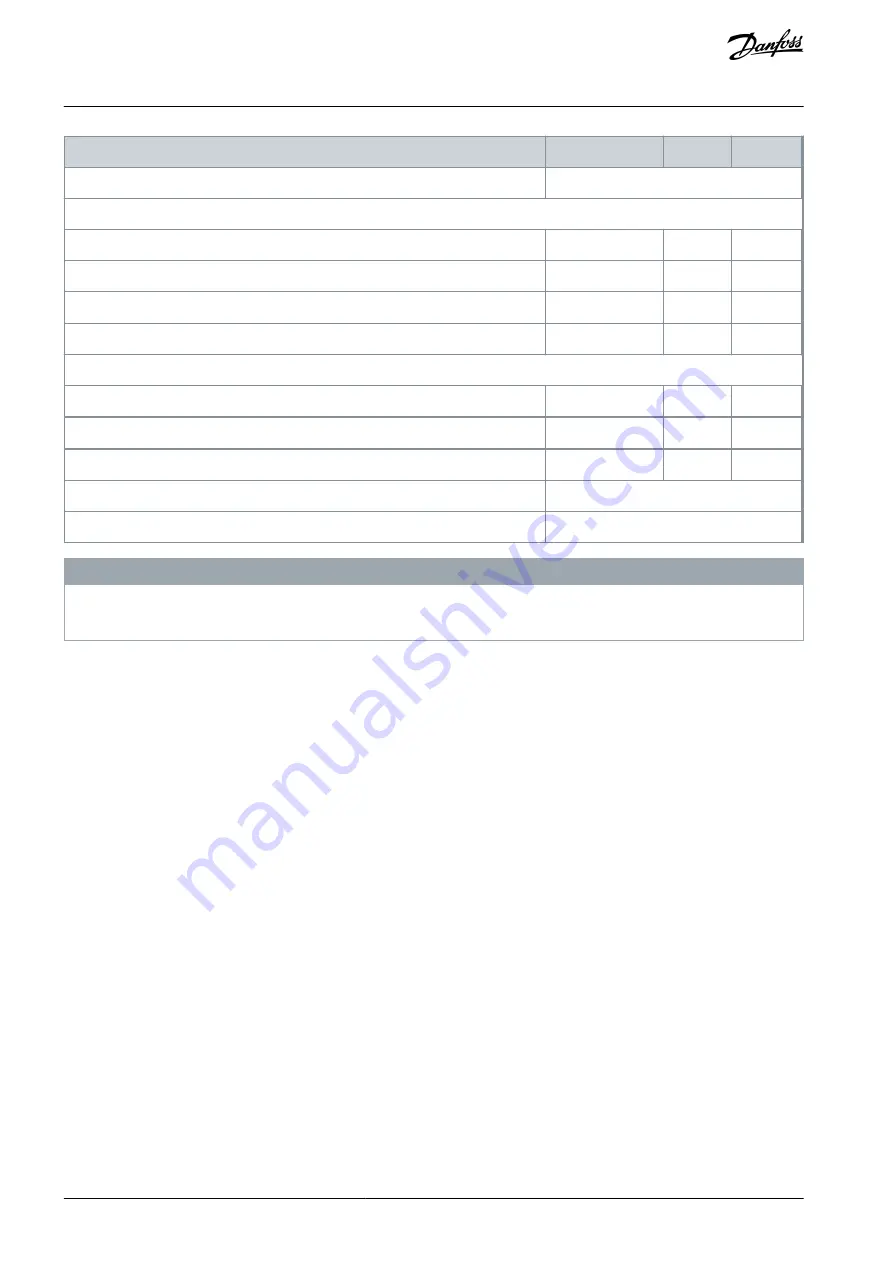

Data

ISD 510/DSD 510

PSM 510

DAM 510

Lifetime

20 years

Data for EN/ISO 13849-1

Performance level (PL)

d

–

–

Category

3

–

–

Mean time to dangerous failure (MTTF

D

)

>5000 years

–

–

Diagnostic coverage (DC)

60%

–

–

Data for EN/ISO 61508 and EN/IEC 62061

Safety integrity level (SIL)

2

–

–

Probability of failure per hour (PFH)

<4 x 10

-9

/h

0 /h

0 /h

Safe failure fraction (SFF)

>95%

100%

100%

Subsystem classification

Type A

Functional test interval

1 year

N O T I C E

The PSM 510, DAM 510, and ACM 510 do not contribute to the dangerous failure rate of the Danfoss system and can there-

fore be excluded from safety-related calculations.

8.11 Maintenance, Security, and User Accessibility

Maintenance: Test the STO safety function at least once per year as follows:

Remove the STO input voltage.

Verify that the motors stop running.

Verify that no unexpected error codes appear.

Security: If security risks exist, take suitable measures to prevent them.

User accessibility: Restrict access to the ISD 510/DSD 510 servo drives and other system components if access to them could result in

safety risks.

AQ262449648484en-000101 / 175R1135

154 | Danfoss A/S © 2020.08

Functional Safety Concept

VLT® Servo Drive System ISD 510/DSD 510

Operating Guide