1.

2.

-

Table 109: Overview of Maintenance Tasks

Component

Maintenance task

Maintenance interval

Instruction

All

Carry out a visual inspection.

Every 6 months

Check for any abnormalities on the

surface.

Shaft seal on the

ISD 511

Check the condition and

check for leakage.

Every 6 months or 3000 operating

hours.

(2)

For more instructions on replacing

the shaft seal, see the

Krones Service

Manual

and

Service Toolkit for Shaft

Sealing

.

If damaged or worn: Replace the

shaft seal.

System modules

Check the fan.

Every 12 months

Check that the fan can turn and re-

move any dust or dirt.

Hybrid cable

Check for damage and wear.

Every 6 months

If damaged or worn: Replace the

hybrid cable.

Functional safety

Perform a system power cy-

cle and check the STO func-

tion.

Every 12 months

Activate STO and check the status

with the PLC.

2

A shorter interval may be necessary depending on the application. Contact Danfoss for more information.

10.4 Repair

Do not attempt to repair the products. Defective products must be returned to Danfoss. Contact the local Danfoss sales company

for information about returns.

10.5 System Module Replacement

10.5.1 Dismounting the System Modules

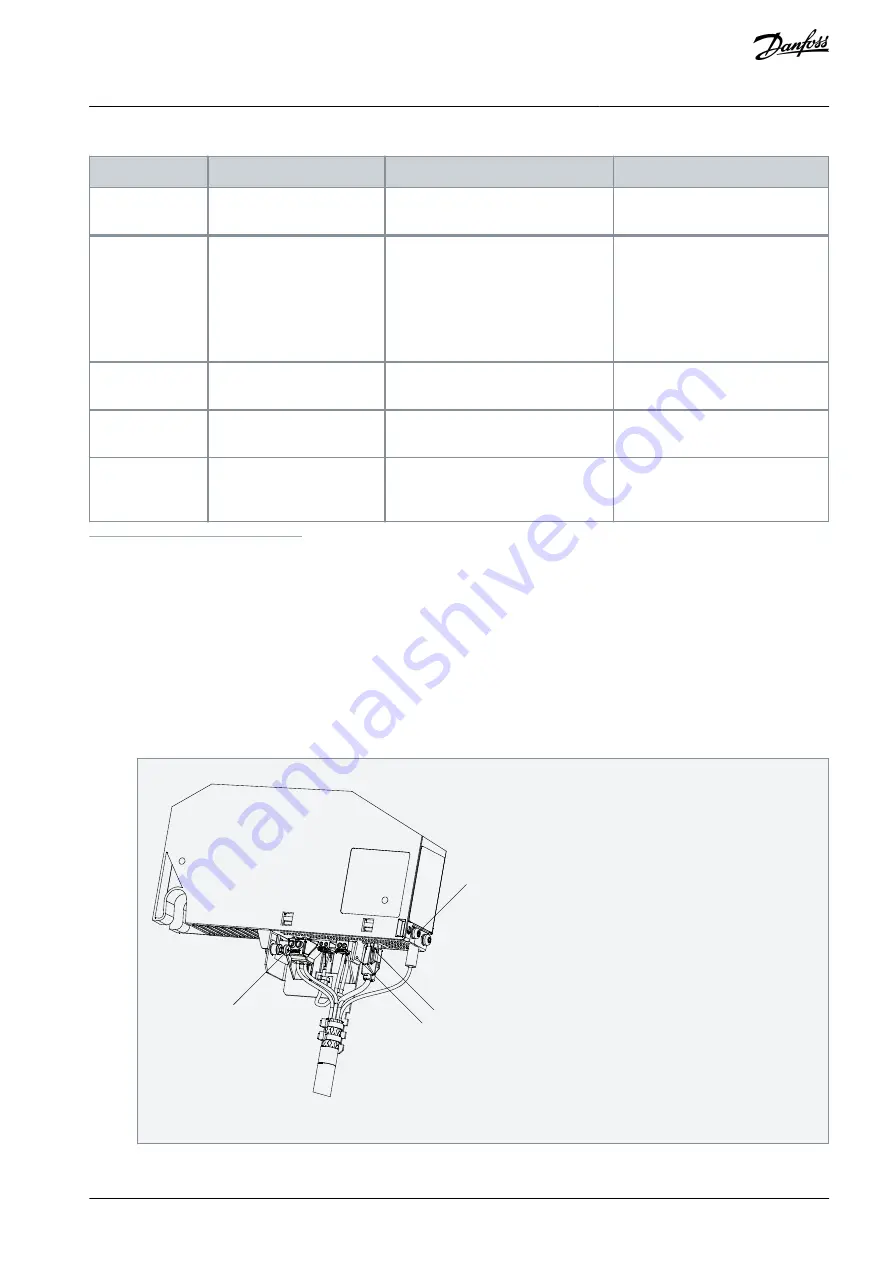

Disconnect the mains and all auxiliary supplies from the PSM 510 and wait for the discharge time to elapse.

Disconnect the EMC plate on the bottom of the system modules. Do not dismount the connectors from the EMC plate.

1

2

3

4

e30bg813.10

Illustration 57: Disconnecting the EMC Plate

Unplug the RJ45 connector [2] (only on DAM 510).

AQ377148425069en-000101

/ 130R1213 | 119

Danfoss A/S © 2023.08

Maintenance, Decommissioning

and Disposal

VLT® Servo Drive System ISD 511

Operating Guide