1.

2.

3.

4.

5.

6.

7.

8.

1.

2.

3.

1

2

3

4

5

6

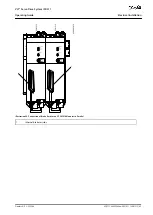

e30bg807.10

Illustration 34: Connecting the Feed-In Cable

1

Feed-in cable PE screws

2

Bus connector

3

Cable tie for feed-in cable

4

Cable tie for STO cable

5

EMC plate

6

EMC plate screw

Procedure

Insert the wires into the UDC, AUX, and STO connectors.

Secure the feed-in cable using the cable ties [3], ensuring that the shielded area is positioned exactly under the cable tie.

Secure the STO cable using the cable tie [4], ensuring that the shielded area is positioned exactly under the cable tie.

Insert the connectors on the feed-in cable into their corresponding terminal block on the DAM 510.

Tighten the screw on the EMC plate [6]. The tightening torque is 3 Nm.

Insert the RJ45 bus connector [2].

Connect the DAM 510 to PE using one of the PE screws on the front side [1] and a PE wire. The tightening torque is 3 Nm.

Connect the PE wire of the feed-in cable to the other PE screw on the DAM 510.

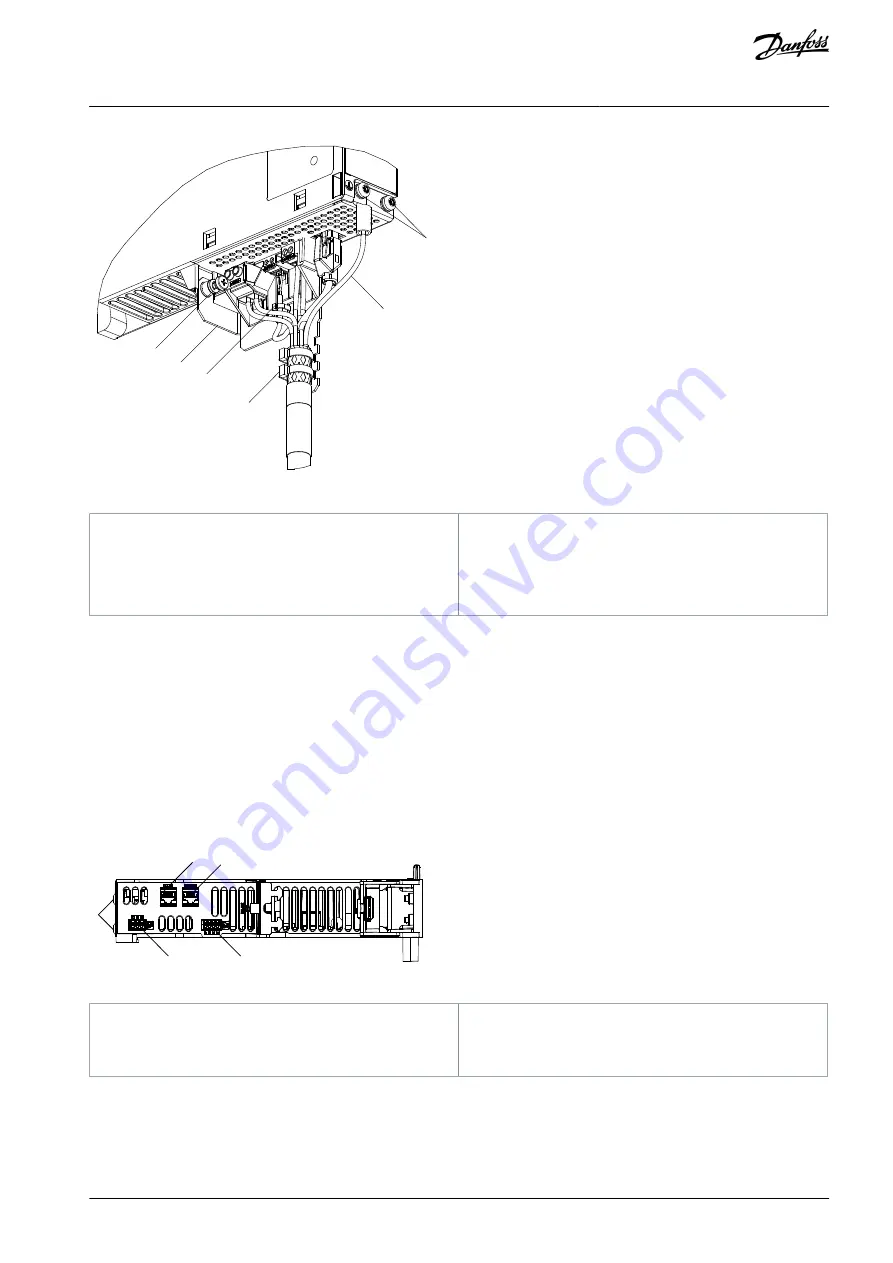

5.9.4 Connecting the Auxiliary Capacitors Module ACM 510

e30bh350

.11

1

2

4

5

3

Illustration 35: Connectors on the Top of ACM 510

1

Ethernet connector IN (X1 IN)

2

Ethernet connector OUT (X2 OUT)

3

I/O connector (I/O ACM)

4

Relay connector (REL ACM)

Procedure

Connect the Ethernet cable from the output of the previous system module to the input connector (X1 IN) [1].

If I/Os are required, insert the wires into the I/O connector (I/O ACM) and insert the connector [3].

If a relay is required, insert the wires into the relay connector (REL ACM) and insert the connector [4].

AQ377148425069en-000101

/ 130R1213 | 61

Danfoss A/S © 2023.08

Electrical Installation

VLT® Servo Drive System ISD 511

Operating Guide