7 Operation

7.1 Operating Modes

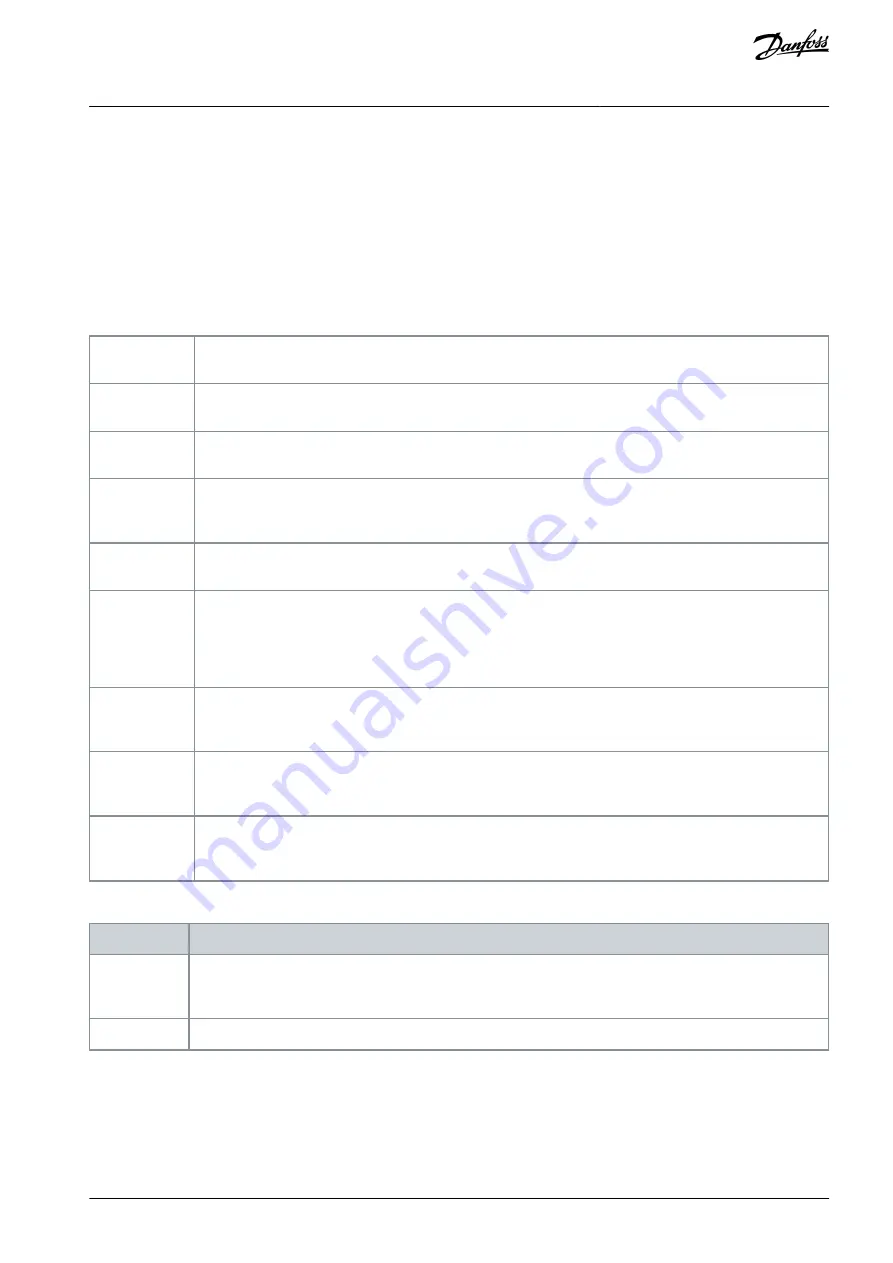

The ISD 511 servo drives implement several modes of operation.

The behavior of the servo drive depends on the activated mode of operation. It is possible to switch between the modes while the

servo drive is enabled.

The supported modes of operation are according to CANopen

®

CiA DS 402 and ISD-specific modes of operation. All supported

modes of operation are available for Ethernet POWERLINK

®

.

The various modes of operation are described in detail in the

VLT® Servo Drive System ISD 510, DSD 510, MSD 510 (VLT® FlexMo-

tion

™

) Programming Guide

.

Inertia meas-

urement mode

This mode measures the inertia of an axis. It is used to measure the mechanical inertia and friction of the servo

drive and the external load to optimize the control loop settings.

Profile velocity

mode

In profile velocity mode, the servo drive is operated under velocity control and executes a movement with

constant speed. Additional parameters, such as acceleration and deceleration, can be parameterized.

Profile position

mode

In profile position mode, the servo drive is operated under position control and executes absolute and relative

movements. Additional parameters, such as velocity, acceleration, and deceleration, can be parameterized.

Profile torque

mode

In profile torque mode, the servo drive is operated under torque control and executes a movement with con-

stant torque. Linear ramps are used. Additional parameters, such as torque ramp and maximum velocity, can

be parameterized.

Homing mode

In homing mode, the application reference position of the servo drive can be set. Several homing methods,

such as homing on actual position, homing on block, limit switch, or home switch, are available.

CAM mode

In CAM mode, the servo drive executes a synchronized movement based on a master axis. The synchroniza-

tion takes place via a CAM profile that contains slave positions corresponding to master positions. CAMs can

be designed graphically with the VLT® Servo Toolbox software, or can be parameterized via the PLC. The guide

value can be provided by an external encoder, virtual axis, or the position of another axis. It is used as the

master position within the synchronous modes.

Gear mode

In gear mode, the servo drive executes a synchronized movement based on a master axis by using a gear ratio

between the master and the slave position. The guide value can be provided by an external encoder, virtual

axis, or the position of another axis. It is used as the master position within the synchronous modes.

Cyclic synchro-

nous position

mode

In cyclic synchronous position mode, the trajectory generator of the position is located in the control device,

not in the servo drive.

Cyclic synchro-

nous velocity

mode

In cyclic synchronous velocity mode, the trajectory generator of the velocity is located in the control device,

not in the servo drive.

7.1.1 Motion Functions

Function

Description

Digital CAM

switch

This functionality controls whether the digital output is enabled or disabled, depending on the axis position. It

performs a function comparable to switches on a motor shaft. Forward and backward movements of the axis

position are allowed. On and off compensation and hysteresis can be parameterized.

Touch probe

This functionality stores the position actual value at a rising or falling edge of the configured digital input.

7.2 Operating Status Indicators

The operating status of the ISD 511 servo drives, PSM 510, DAM 510, and ACM 510 is indicated via the LEDs on each device.

AQ377148425069en-000101

/ 130R1213 | 83

Danfoss A/S © 2023.08

Operation

VLT® Servo Drive System ISD 511

Operating Guide