21. In the

Attach Variable port (Input)

window, select [PLC-Configuration

→

MyFirstIsd510Project

→

Standard

→

.myAxis.NodeNumber].

22. Click on

OK

.

6.12.13 Transferring the Mappings back to the PLC Program

To transfer the mappings back to the PLC program, select

Activate Configuration...

in menu item

Actions

.

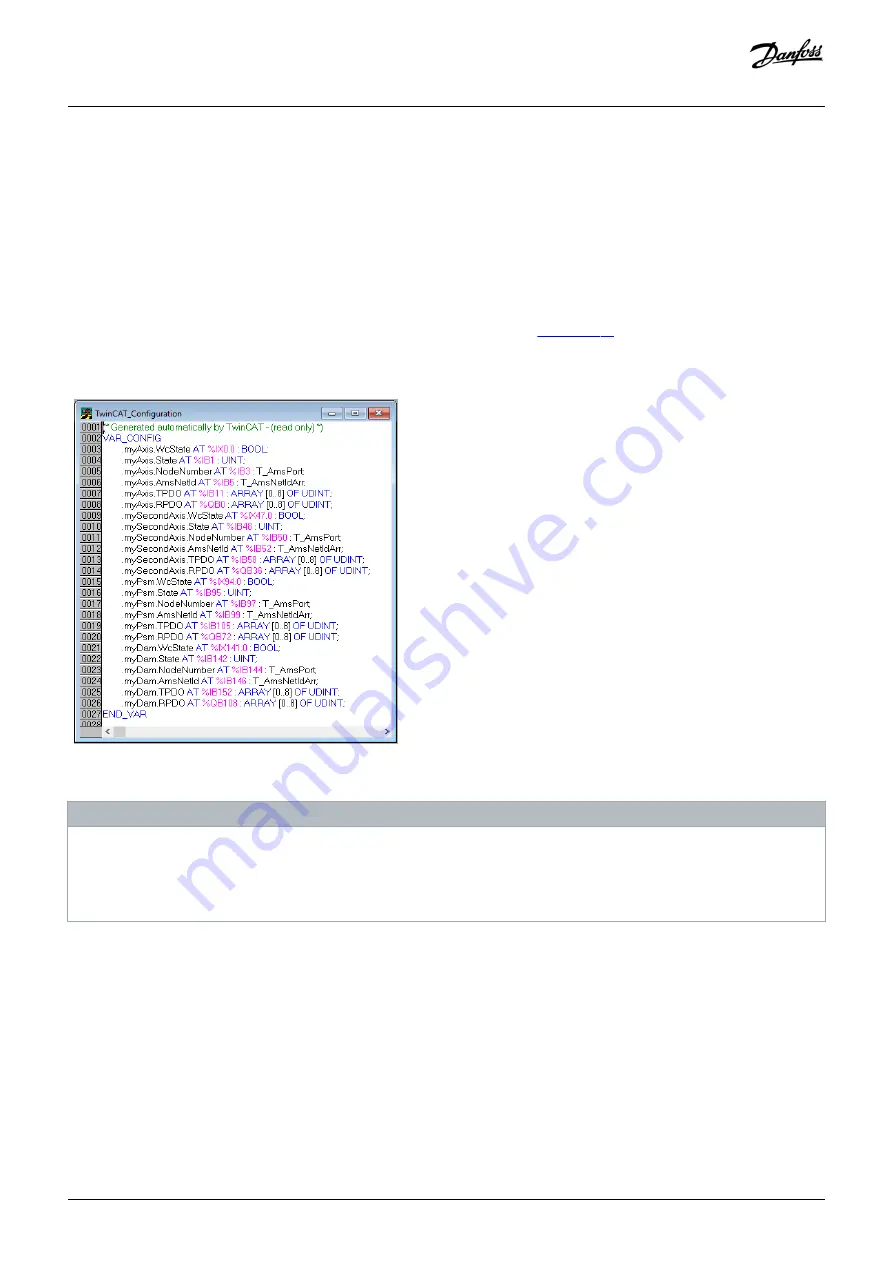

After a rebuild in TwinCAT

®

PLC Control, the TwinCAT

®

(here

myAxis

and

mySecondAxis

are

instances of

AXIS_REF_DDS

,

myPSM

is an instance of

PSM_REF

, and

myDAM

is an instance of

DAM_REF

). The concrete addresses can be

different.

e3

0b

h5

20

.1

0

Illustration 79: TwinCAT

®

Configuration: I/O Mapping of 2 Servo Drives, 1 PSM 510, and 1 DAM 510

NOTICE

-

Connect the PSM 510, DAM 510, ACM 510, and SDM 511/SDM 512 to 1 SYNC unit and the ISD 510/DSD 510 servo drives to

another. This protects against interruptions in communication to the PSM 510 and DAM 510 if the U

AUX

supply to the

decentral servo drives is switched off due to an error.

6.12.14 Setting the PLC Cycle Time in TwinCAT® PLC Control

Context:

The minimum cycle time is 400 µs. The MSD 510 devices can run EtherCAT

®

cycle times in multiples of 400 µs or 500 µs. The devices are

automatically parameterized by the PLC on start-up, depending on the EtherCAT

®

configuration of the physical interface. To access the

system base time, select [SYSTEM-Configuration

→

Real-Time Settings] in the TwinCAT

®

System Manager. Multiples of this base time

can then be used as EtherCAT

®

cycle times.

Commissioning

Operating Guide | VLT® Multiaxis Servo Drive MSD 510 System

AQ262450196490en-000101 / 175R1170

110 | Danfoss A/S © 2019.10

Summary of Contents for VLT MSD 510

Page 1: ...Operating Guide VLT Multiaxis Servo Drive MSD 510 System...

Page 2: ......