6 Maintenance, Diagnostics and Troubleshooting

WARNING

HIGH VOLTAGE

High voltage, which can lead to death or serious injury,

is present on the connectors.

•

Before working on the power connectors

(disconnecting or connecting the cable),

disconnect the power supply module from line

power and wait for the discharge time to

elapse.

•

Installation, start-up, maintenance, and

decommissioning must be performed by

qualified personnel only.

CAUTION

DANGER OF BURNS

The surface of the OneGearDrive and the oil in the

OneGearDrive can reach high temperatures during

operation.

•

Do not touch the OneGearDrive until it has

cooled down.

•

Do not carry out an oil change until the oil has

cooled down sufficiently.

6.1 Maintenance

To prevent breakdown, danger and damage, examine the

OneGearDrive at regular intervals depending on the

operating conditions. Replace worn or damaged parts

using original spare parts or standard parts.

Contact your local service representative for service and

support:

www.danfoss.com/Contact/Worldwide/

The OneGearDrives are largely maintenance free. The

maintenance tasks listed in

may be performed by

the customer. No other tasks are required.

Component

Maintenance

task

Maintenance

interval

Instruction

OneGearDrive

Check for

abnormal

noise and

vibration.

Every 6

months.

Contact

Danfoss

Service.

Protective

coating

Check for

damage.

Every 6

months.

Repair damage

using the

Danfoss paint

repair set.

Hollow shaft

seal (stainless

steel shaft)

Check the

condition and

check for

leakage.

Every 6

months.

If damaged,

replace with a

Viton seal.

Hollow shaft

seal (mild steel

shaft)

Check the

condition and

check for

leakage.

Every 6

months.

If damaged,

replace with

an NBR seal.

Oil

Change the oil. Standard oil:

After 25,000

operating

hours.

Food grade oil:

After 35,000

operating

hours.

See

Check for oil

leakage on

gear and

motor housing.

Every 12

months.

Replace the

OneGearDrive.

Table 6.1 Overview of Maintenance Tasks

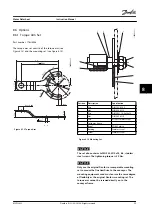

6.1.1 Replacing the Brake and Rotor

All work must only be carried out by qualified technical

personnel on a stationary machine that has been protected

against restarting. This also applies to auxiliary circuits.

Maintenance, Diagnostics an...

Instruction Manual

18

Danfoss A/S © 08/2014 All rights reserved.

MG75C422

6

6