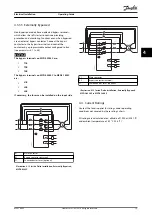

4.2.2 MCD5-0245C

MCD5-0245C has dedicated bypass terminals at the bottom

of the unit. The bypass terminals are:

•

T1B.

•

T2B.

•

T3B.

177HA651.10

1/L1 3/L2 5/L3

T1B T2B T3B

2/T1 4/T2 6/T3

Illustration 4.4 Bypass Terminals on MCD5-0245C

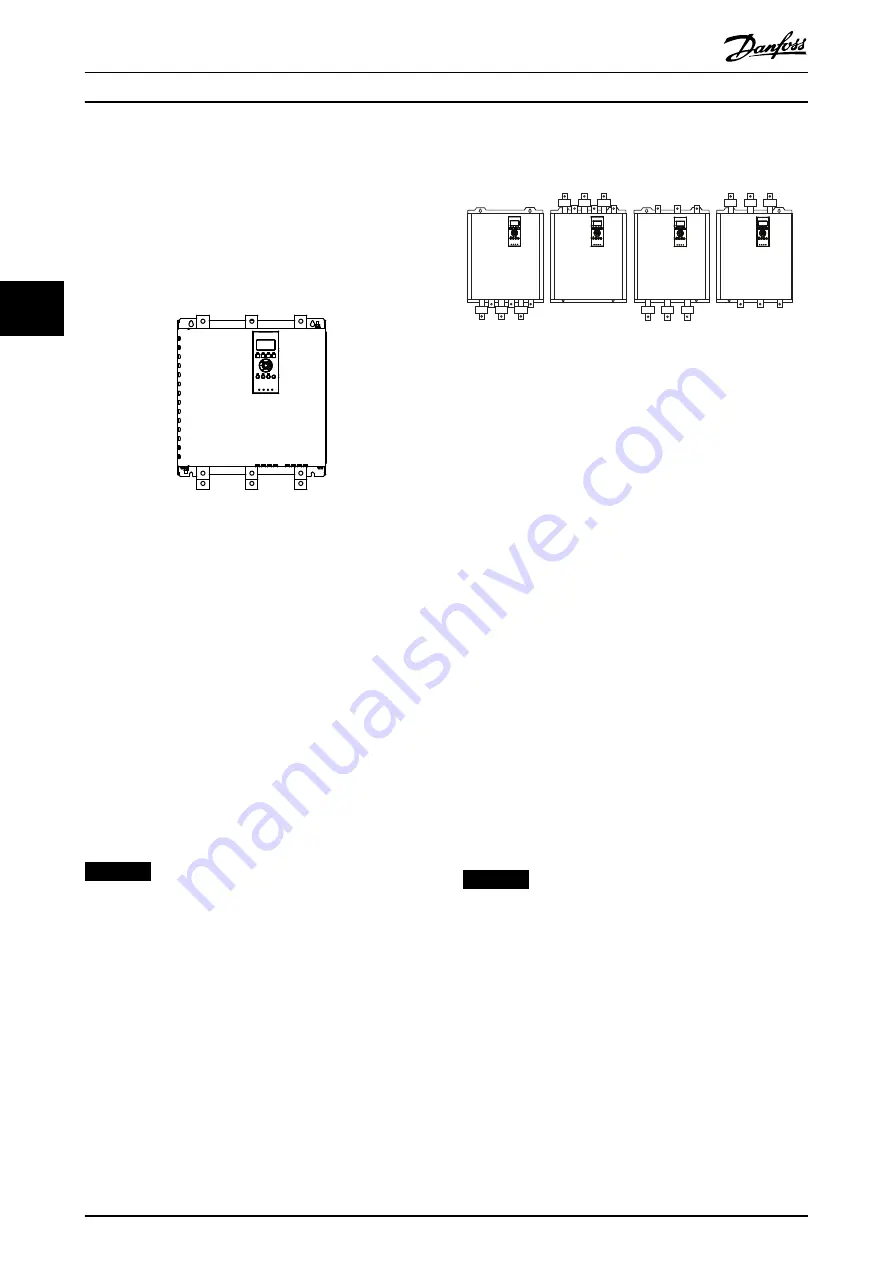

4.2.3 MCD5-0360C to MCD5-1600C

MCD5-0360C to MCD5-1600C have dedicated bypass

terminals on the input busbars. The bypass terminals are:

•

L1B

•

L2B

•

L3B

The busbars on non-bypassed models MCD5-0360C to

MCD5-1600C can be adjusted for top or bottom input and

output as required. See

Procedure (MCD5-0360C to MCD5-1600C)

for step-by-step

instructions. The soft starters are manufactured top-in/

bottom-out.

NOTICE

For models MCD5-0360C to MCD5-1600C to be UL-

compliant, mount them

top-in, bottom-out

, or

top-out,

bottom-in

. See

chapter 11.1 UL-compliant Installation

for

more information.

(L1B L2B L3B)

1/L1 3/L2 5/L3

2/T1 4/T2 6/T3

1/L1 3/L2 5/L3

(L1B L2B L3B)

2/T1 4/T2 6/T3

(L1B L2B L3B)

1/L1 3/L2 5/L3

2/T1 4/T2 6/T3

1/L1 3/L2 5/L3

(L1B L2B L3B)

2/T1 4/T2 6/T3

177HA652.10

Illustration 4.5 Location of Bypass Terminals, MCD5-0360C to

MCD5-1600C

4.3 Motor Connection

VLT

®

Soft Starter MCD 500 soft starters can be connected

to the motor in-line or inside delta (also called 3-wire and

6-wire connection). When connecting in inside delta, enter

the motor full load current (FLC) for

parameter 1-1 Motor

Full Load Current

. The MCD 500 automatically calculates

inside delta current based on this data.

Parameter 15-7

Motor Connection

is set to

Auto Detect

as default and can

be set to force the soft starter in inside delta or in-line.

4.3.1 Testing the Installation

The VLT

®

Soft Starter MCD 500 can be connected to a

small motor for testing. During this test, the control input

and relay output protection settings can be tested. This

test mode is not suitable for testing soft starting or soft

stopping performance.

The minimum FLC of the test motor is 2% of the minimum

FLC of the soft starter (see

NOTICE

When testing the soft starter with a small motor, set

parameter 1-1 Motor FLC

to the minimum allowable

value.

Models which are internally bypassed do not require an

external bypass contactor.

Electrical Installation

VLT

®

Soft Starter MCD 500

16

Danfoss A/S © 05/2016 All rights reserved.

MG17K602

4

4