VLT

®

2800 Series

■

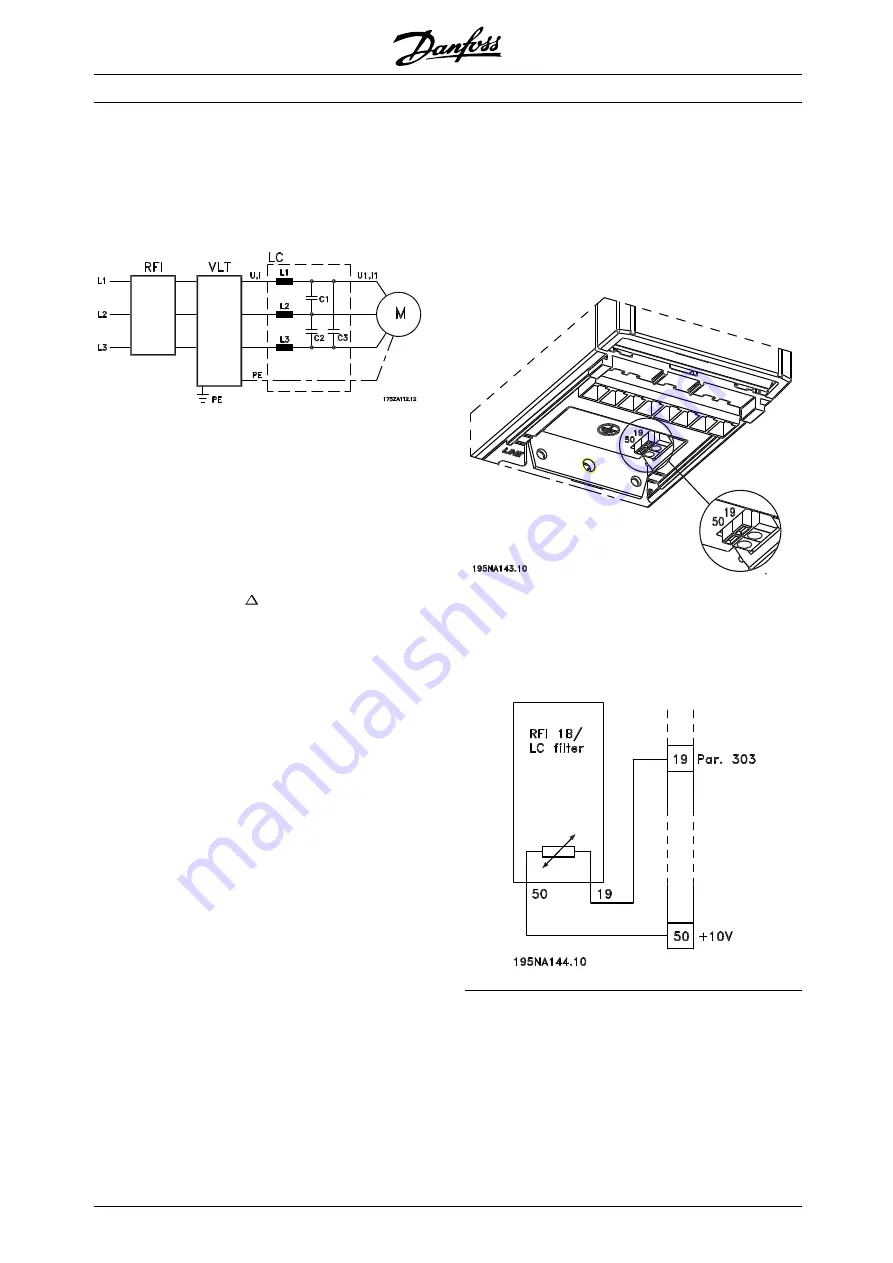

RFI 1B/LC filter

The RFI 1B/LC filter contains both an RFI module

that complies with EN 55011-1B and an LC filter

that reduces the acoustic noise.

LC filter

When a motor is controlled by a frequency converter, at

times you will be able to hear the acoustic noise from

the motor. The noise, which is caused by the design of

the motor, is generated every time one of the inverter

contacts in the frequency converter is activated. The

frequency of the acoustic noise therefore corresponds

to the frequency converter

’

s connection frequency.

The filter reduces the voltage

’

s du/dt, the peak voltage

U

peak

and ripple current

I to the motor, so that the

current and voltage are almost sine-shaped. The

acoustic motor noise is thus reduced to a minimum.

Because of the ripple current in the coils some

noise will be emitted by the coils. This problem

can be solved completely by fitting the filter

inside a cabinet or equivalent.

Danfoss can supply an LC filter for the frequency

converter, which muffles the acoustic motor noise.

Before the filters are put into use you must ensure that:

-

rated current is observed

-

mains voltage is 200-480 V

-

parameter 412

Variable switching frequency

is set to

LC filter attached

[3]

-

output frequency is max. 120 Hz

See drawing on the next page.

Installation of thermistor (PTC)

The RFI 1B/LC filter has an integral thermistor (PTC),

which is activated if an overtemperature arises. The

frequency converter can be programmed to stop the

motor and activatee an alarm via a relay output or

a digital output if the thermistor is activated.

The thermistor must be connected between terminal 50

(+10V) and one of the digital inputs 18, 19, 27 and 29.

In parameter 128

Motor thermal protection Thermistor

warning

[1] or

Thermistor trip

[2] are selected.

The thermistor is connected as follows:

MG.28.E9.02 - VLT is a registered Danfoss trademark

14