50 DKDHR

VI.GP.P1.02

Danfoss District Energy

Instructions

VX Solo II

13.0 Maintenance

Maintenance work

Is only to be carried out by qualified and authorised personnel.

Inspection

The operator or other authorised personnel is obliged to perform in-

spections at regular intervals and if necessary carry out maintenance

work according to these and other instructions. Within the scope of the

above maintenance work all strainers should be cleaned, all connections

should be tightened and the operation of the safety valves should be

checked by turning the valve head in the indicated direction.

Rinsing/cleaning of plate heat exchanger

Brazed heat exchangers can be rinsed. For optimum cleaning the flow

rate should be a min. of 1.5 times normal flow rate, preferably in back-

flush mode. This will remove any deposits formed on the inside of the

plate heat exchanger. In case of more serious deposits, a cleaning liquid,

approved by Danfoss (f.ex. Kaloxi or Radiner FI) can be pumped through

the heat exchanger. Both are environmentally friendly cleaning fluids

and can be disposed of through the usual domestic sewerage system.

Afterwards rinse thoroughly with large amounts of water.

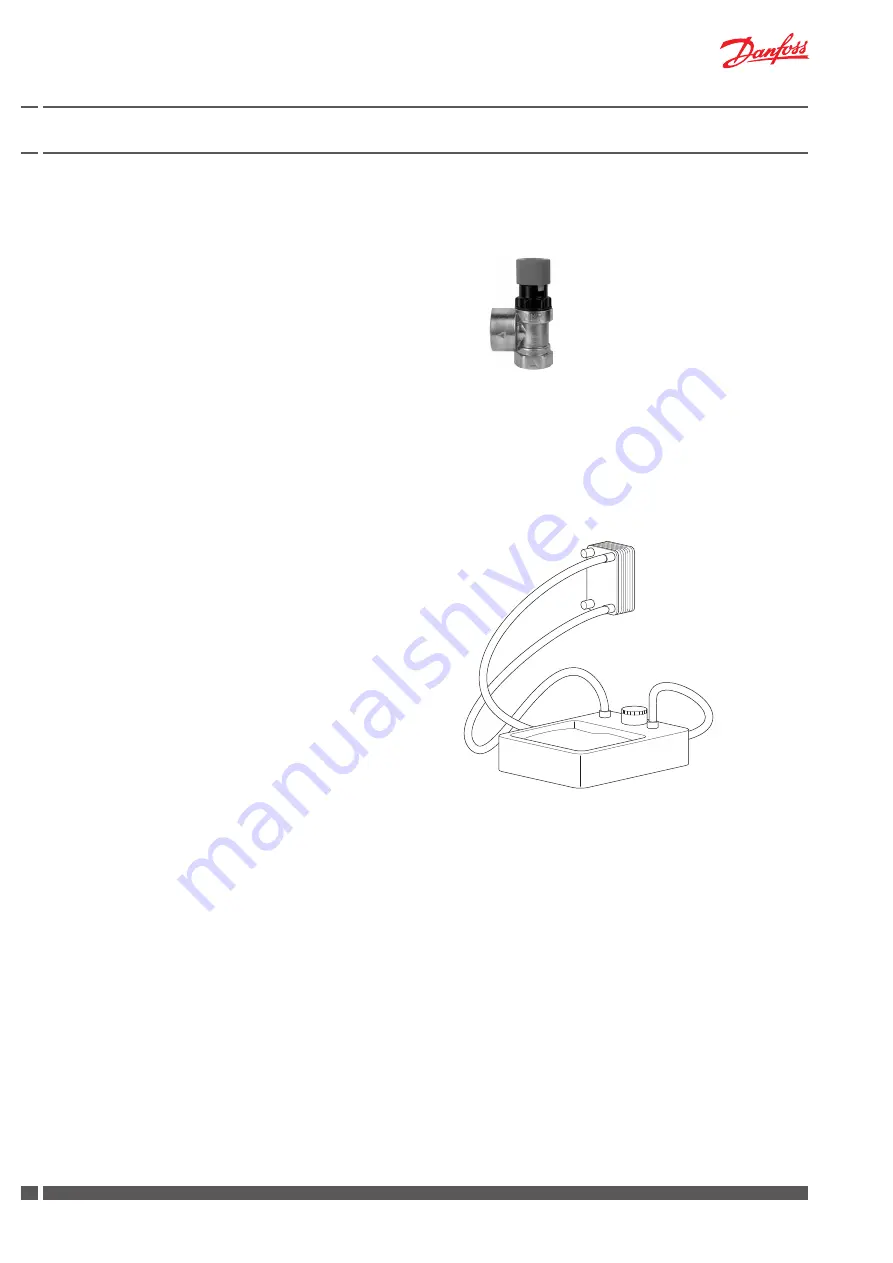

Deacidification of plate heat exchanger

After long operation, because of the relatively high temperatures in

the plates or tubes, the heat exchangers are expecially subject to

calification. Any deacidification of the plate heat exchanger is done as

shown on the drawing to the right. For brazed plate heat exchangers

weak inhibited acid solutions (e.g. 5% formic, acetic or phosphoric acid)

may be used.

Measures after maintenance work

After maintenance work and before switching the system on again:

– Check that all screwed connections are tight.

– Check that all safety features, covers, that were removed, have been

replaced properly.

– Clean the working area and remove any spilled materials.

– Make sure that all tools, materials and other quipment that were

used, have been removed from the working area.

– Connect to energy supply and check for leaks.

– Vent the system.

– If necessary adjust the system again.

– Make sure that all safety features on the device and the system work

properly.

For the janitor or other supervisors

Meter reading

It is recommended to read the heat meter at regular intervals, and to

write down the meter readings.

Cooling / Return temperature reading

The cooling, i.e. the temperature difference between district heating

supply and district heating return is of great importance for the total

heat economy. It is therefore very important to observe the supply

and return temperatures. Normal temperature difference is 30-35 °C.

Please note, that the lowest district heating return temperature is di-

rectly dependent on the return temperature from the heating circuit

and the cylinder circuit. Therefore, please observe these return tem-

peratures.

Tightening of connections

When reading the heat meter, all fittings and connections should be

checked for leaks. If leaks are detected, contact qualified and authori-

zed personnel immediately.

Please note that the connections may be supplied with EPDM rub-

ber gaskets - in general connection sizes from ¾” to and incl. 1½”

for Kompakt H stations. Therefore take care not to overstrain the

union nuts, as this may result in leaks. The manufacturer accepts

no liability for leaks that result from overstrain of union nuts.