Application guidelines

61

FRCC.PC.023.A7.22

Single compressors

Installation

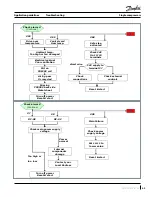

High voltage test

It is not necessary to perform a Hipot test

(dielectric withstand test) on frequency

converters. This has already been done during

factory final test.

If a Hipot test has to be done anyway, following

instructions must be followed in order to not

damage the frequency converter:

• Compressor not connected

• L1, L2, L3, U, V, W terminals must be shorten

and connected to high voltage terminal of the

testing device.

• Ground terminal (chassis) must be connected to

low voltage terminal of the testing device.

• 2000VDC(for T2)/2150VDC( for T4)/2250VDC (for

T6) for 1 seconds must be applied

• Ramp up time 3 seconds

• Full DC voltage must be established during 2

seconds

• The current leakage during the test must be

below 1mA

• Ramp down time to 0V in 25 seconds.

When running high voltage tests of the

entire installation, frequency converter and

compressor electrical motor compressor test

can be conducted together. When conducting

a high voltage test make sure the system is not

under vacuum: this may cause electrical motor

compressor failure.

L1 L2 L3

91 92 93

U V W PE

96 97 98 99

NET

MOTOR

R- R+

81 82

01 02 03

- 24V + - DC +DC

35 36 88 89

MOTOR

NET

95

94

2 20 200 2000MOhm

+

-

20 ohm

M ohm

Gossen - ISOWID - 0413

M ohm

V

Ohm

On M Ohm 2000 M Ohm

System pressure test

Always use an inert gas such as nitrogen for

pressure testing. Never use other gasses such as

oxygen, dry air or acetylene as these may form

an inflammable mixture. Do not exceed the

following pressures:

Pressurize the system on HP side first then LP side

to prevent rotation of the scroll. Never let the

pressure on LP side exceed the pressure on HP

side with more than 73 psi.

Maximum compressor test pressure (low side)

483 psi(g) for VZH088 & 117

438 psi(g) for VZH170

Maximum compressor test pressure (high side)

653 psi(g)

Maximum pressure difference between high and low side

of the compressor

537 psi