Application guidelines

85

FRCC.PC.023.A7.22

Manifold compressors

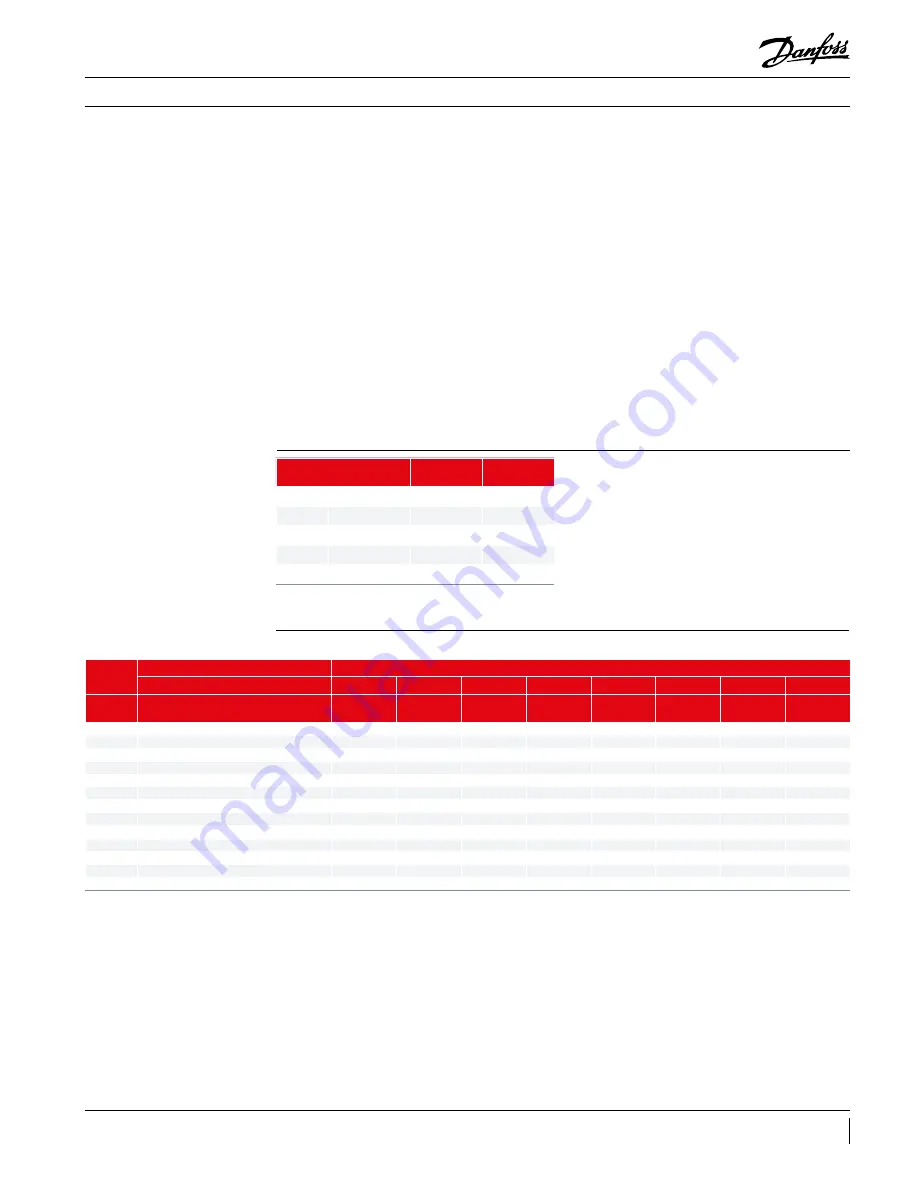

Ordering information

Ordering information

Mounting kit for rubber

connection

Manifolding kit 24V Type

To build a complete tandem, customers must

order 2 compressors and 1 manifolding kit

and 1 mounting kit(for VZH170 hybrid rubber

connection). Manifolding kit selection should

base on compressor models and oil level switch

voltage.

Please note for VZH170 hybrid manifolding,

rigid spacers is delivered with compressor

SH180/240/295 please leave rigid connection

when rubber connection is adopted.

For rubber connection:

·

VZH088:1FS+1VS+1new manifolding kit

·

VZH117:1FS+1VS+1new manifolding kit

·

VZH170: 1FS+1VS+1new manifolding kit+1

rubber mounting kit(8156138)

Ordering example:

VZH1SH180 code 4, 24V type:

·

Rubber grommet solution:

·

1x VZH170(121x SH180(120H0267)

+1 x new manifolding kit(121x

rubber mounting kit(8156138)

Danfoss VZH and SH scroll compressors can

be ordered in either industrial packs or in

single packs. Please refer to single compressor

application guideline for ordering. The tandem

kits can be ordered with code numbers from

below table.

Note: rubber mounting kit for manifolding is the same as single

compressor mounting kit.

Hybrid

VZH088/117

VZH170

No

Code number

120Z0066

8156138

14

grommet

4

4

15

sleeve

4

4

16

bolt

4

4

17

washers

4

4

24VAC/

VDC type

Code Number

New code number

120Z0586

120Z0587

120Z0588

120Z0589

120Z0590

120Z0591

120Z0592

120Z0593

No

Description

SH090

SH120

SH140

SH161

SH184

SH180

SH240

SH295

1

Oil level monitor-Electrical part

1

1

1

1

1

1

1

1

2

Organ pipe Nelico

2

2

2

2

2

3

Sleeve 1 1/8"

2

2

2

2

2

4

Sleeve 1 3/8"

2

2

2

5

Teflon gasket 1 1/8"

2

2

2

2

2

6

Teflon gasket 1 3/8"

2

2

2

7

Restrictor SH090

1

8

Restrictor SH120

1

9

Restrictor SH140/SH161

1

1

10

Restrictor SH184

1

11

Restrictor SH180

1

12

Restrictor SH240

1

13

Rigid spacer 7mm

4

4