DanTaet a/s

User Manual System KMP-V

110101 func. spec. 160926

Doc.No. 417106

Revision 170823

Page 20 of 26

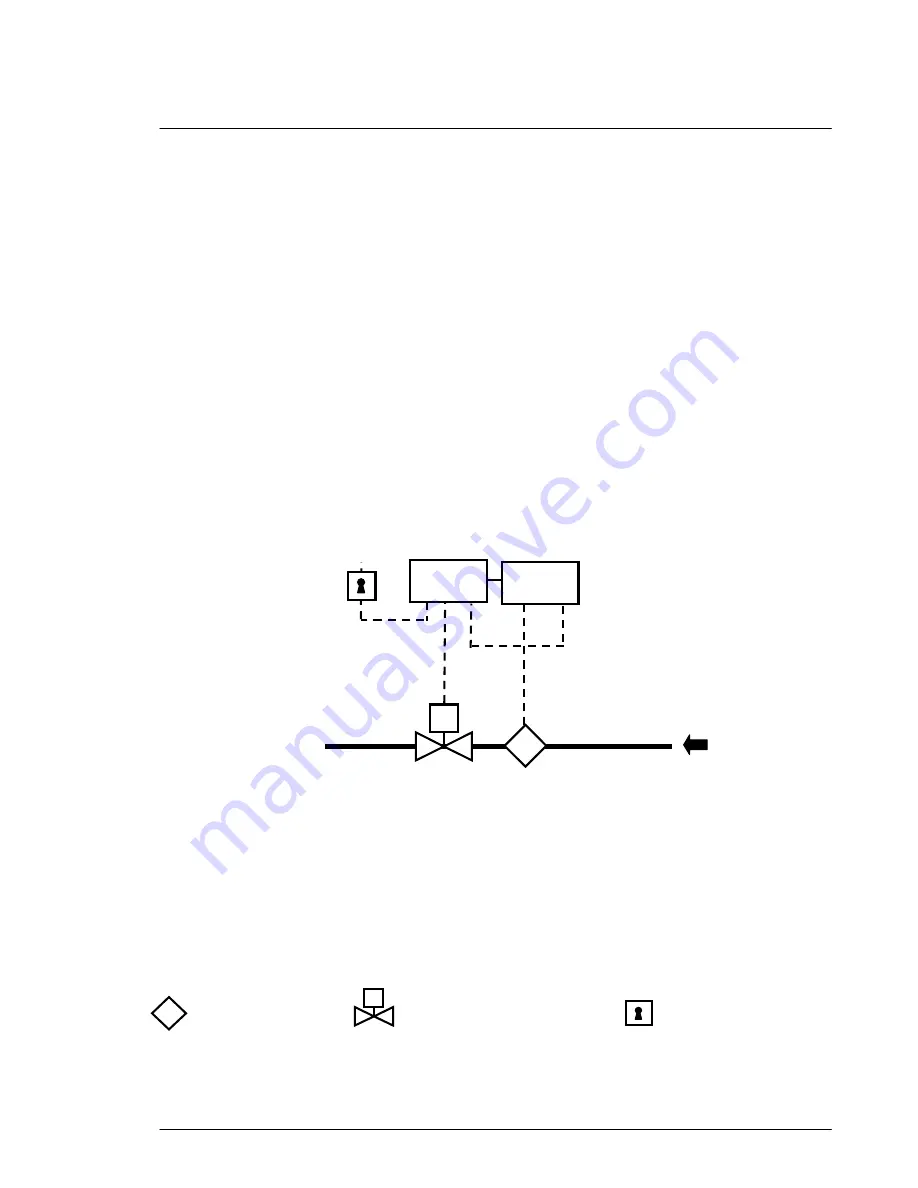

Plumbing

Meter and valve are installed as illustrated.

Meter

Kamstrup ultrasonic water meter to be installed as per manufacturer’s instructions.

Cut-off Valve

Electrically actuated ball or butterfly valve, 24Vac supplied from KMP-V. The valve can

be installed with any orientation with the actuator pointing upwards or sideways, not

below the horizontal plane.

Supply Water Installation System KMP-V

Legend:

Flow meter

Cut-off Valvel

Key Switch 230Vac

M

To Consumer

From Utility

KMP-V

230Vac

M

MULTICAL

62