Page 10 of 14

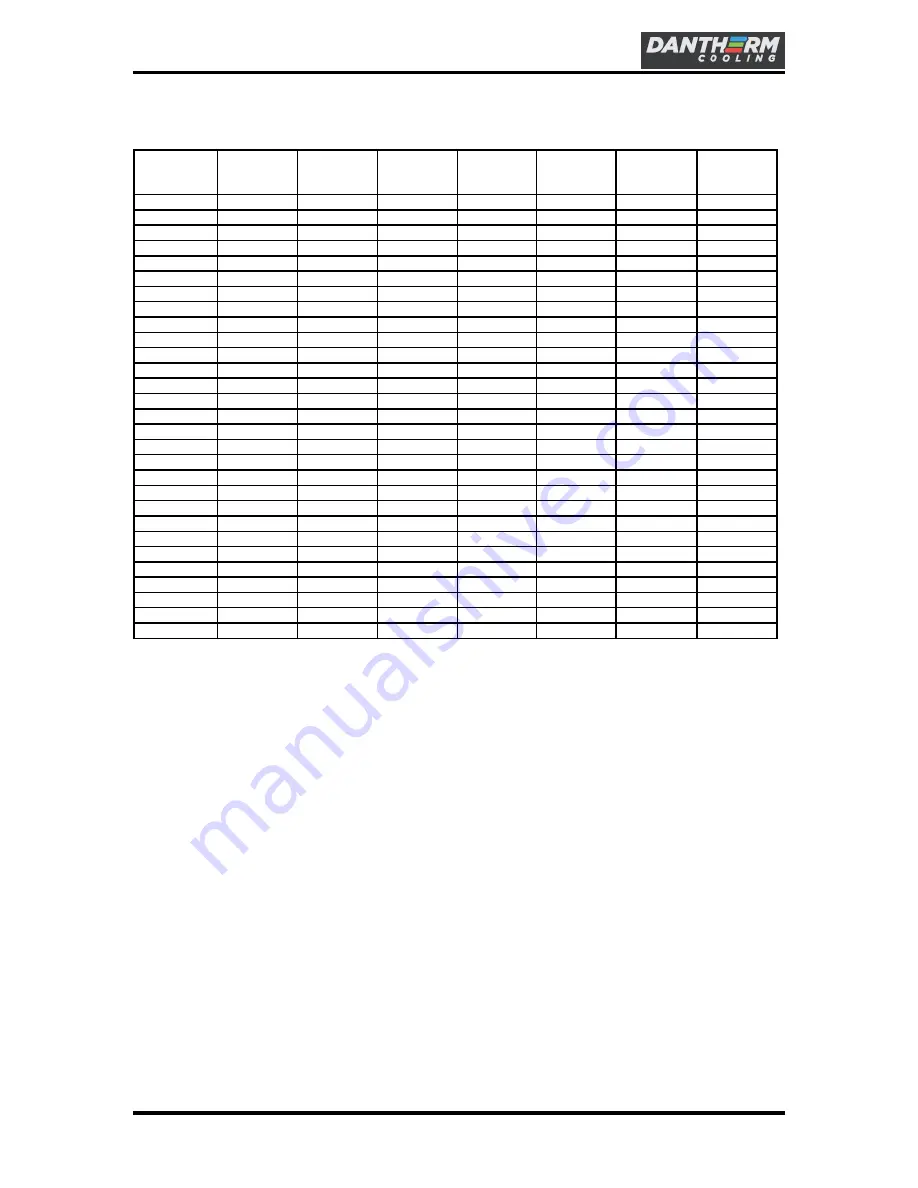

7. DESIGN DATA: GENERAL PERFORMANCE

Model #

Watts/°F

Voltage

Hz

Ph

Full load,

Amps

Minimum

breaker/fuse

size, Amps

Approx.

Weight

(lbs/Kg)

PS018017Y

17

24VDC

N/A

N/A

3.5

4.4

21/9.5

PS018017Z

17

48VDC

N/A

N/A

1.75

2.25

21/9.5

PS023017A

17

115VAC

50/60

1

0.5

0.7

21/9.5

PS023017B

17

230VAC

50/60

1

0.3

0.4

21/9.5

PS023017Y

17

24VDC

N/A

N/A

3.5

4.4

21/9.5

PS023017Z

17

48VDC

N/A

N/A

1.75

2.25

21/9.5

PS023022A

22

115VAC

50/60

1

0.5

0.7

23/10.4

PS023022B

22

230VAC

50/60

1

0.3

0.4

23/10.4

PS023022Y

22

24VDC

N/A

N/A

3.5

4.4

23/10.4

PS023022Z

22

48 VDC

N/A

N/A

1.75

2.25

23/10.4

PS023026Z

26

48VDC

N/A

N/A

1.75

2.25

36/16

PS035035A

35

115VAC

50/60

1

3.4

6

59/27

PS035035B

35

230VAC

50/60

1

0.86

2.5

59/27

PS035035Z

35

48VDC

N/A

N/A

4.3

6

59/27

PS035045A

45

115VAC

50/60

1

3.4

5

64/29

PS035045B

45

230VAC

50/60

1

1.86

2.5

64/29

PS035045Z

45

48VDC

N/A

N/A

4.3

6

60/27

PS035055A

55

115VAC

50/60

1

3.4

5

72/33

PS035055B

55

230VAC

50/60

1

1.86

2.5

72/33

PS035055Y

55

24VDC

N/A

N/A

10.0

12.5

68/31

PS035055Z

55

48VDC

N/A

N/A

4.3

6

68/31

PS060100B

100

230VAC

50/60

1

1

1.5

135/62

*The information provided above is a general overview for reference only. The customer is

responsible for the correct installation and application of each product. As products and features

change, the nameplate on the side of the unit should be referred to for correct voltage / current

during installation.

8. MAINTENANCE

The Heat Exchanger should be examined periodically to determine the required cleaning periods based

on the installed environmental conditions. Annual inspections are most typical and will cover the

majority of installed locations.

CAUTION!

Always disconnect power to Heat Exchanger prior to servicing. Scheduled maintenance

includes cleaning of fans and Heat Exchanger core as they become contaminated with dust or residue.

The fans and Heat Exchanger core should be cleaned using a soft bristle brush to remove dust or

debris. Water is NOT recommended. Reconnect power after service.

8.1.

Wiring Diagrams

The following schematics are of standard products only. Wiring schematics of options or

custom products is available directly from Dantherm Air Handling, Inc.

Dantherm

Cooling

, Inc. Heat Exchanger Operating & Maintenance Manual

HexFlow Pinnacle Series Product Information Manual