31

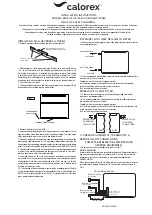

Maintenance and care

: Trouble shooting

Solution

-

Replac

e fan

Replac

e fan

Replac

e t

emper

a-

tur

e sensor

Clean c

ondenser c

oil

Replac

e t

emper

a-

tur

e sensor

Replac

e sensor

M

ov

e displa

y closer

.

Change ba

tt

er

ies

in r

emot

e c

on

tr

ol

panel

.

Fault finding

See LPC

o fault finding pr

oc

edur

es

Confir

m fan is w

or

king

.

If fan swit

ches off f

or no appar

en

t r

eason it is

likely caused b

y the in

ter

nal fan mot

or ther

-

mal pr

ot

ec

tion cir

ctuit

. I

t will disable the fan if

the winding t

emper

atur

e is t

oo high.

Confir

m fan is w

or

king

.

M

easur

e r

esistanc

e of the t

emper

atur

e pr

obe

bet

w

een the

“”

cond

”” and

“”

gnd

”” t

er

minals in

the

“”

temp

”” sec

tion of the PCB

.

Resistanc

e should be in the r

ange 190kOhm -

0,14kOhm, c

or

responding t

o -50..98°C.

If r

esistanc

e is not within this r

ange the sensor

is def

ec

tiv

e or sensor cable is br

oken/shor

t

cir

cuit

ed

Inspec

t c

ondensor c

oil fins f

or dust/debr

is

.

M

easur

e r

esistanc

e of the t

emper

atur

e pr

obe

bet

w

een the t

er

minals of the c

or

responding

sensor in the

“”

temp

”” sec

tion of the PCB

.

Resistanc

e should be in the r

ange 190kOhm -

0,14kOhm, c

or

responding t

o -50..98°C.

If r

esistanc

e is not within this r

ange the sensor

is def

ec

tiv

e or sensor cable is br

oken/shor

t

cir

cuit

ed

Confir

m if the sensor and/or cable is visibly

damaged

.

Check tha

t r

emot

e c

on

tr

ol panel is On.

Check ba

ttt

er

ies in r

emot

e c

on

tr

ol panel

.

Unit b

eha

viour

LP fault is tr

igger

ed

.

HP fault is tr

igger

ed

Unit seemingly oper

ating nor

mally

, self check will

reset fault c

ondition

HP fault is tr

igger

ed

. S

elf-t

est will not r

eset the

fault c

ondition

HP fault is tr

igger

ed

self check will not r

eset fault c

ondition

Displa

y sho

w

s SENS er

ror f

ollo

w

ed b

y E

VAP or

COND when ar

ro

w key

s ar

e pr

essed

, indica

ting

fault in either c

ondenser or ev

apor

at

or sensor

Displa

y sho

w

s SENS er

ror f

ollo

w

ed b

y R

h°t when

ar

ro

w key

s ar

e pr

essed indica

ting failur

e of the

combined t

emp

./RH-sensor

.

-

Possible c

ause

LPC

o fault has been tr

igger

ed t

oo man

y times

consecutiv

ely

Fan failur

e, per

iodic

Fan failur

e

HP t

emper

atur

e sensor fault

Condenser c

oil clogged

Sensor malfunc

tion

Lost c

ommunica

tion t

o pair

ed r

emot

e c

on

tr

ol

panel

Fault

LP fault

HP fault

Sensor failur

e

-

Ty

pe

A

lar

m

A

lar

m

A

lar

m

In

fo

D

ispla

y t

ex

t

LP

HP

SENS

LOSS

en