Planning of service inspections, overview

Introduction

This section describes the parts that need regular service.

See separate descriptions for the kind of service needed and the practical performance.

Categories

Dantherm Air Handling has categorized the service inspections into the following:

•

4 times annually

•

Every 5000 operation hours and at least once annually

•

Once annually

•

When the catalogue value for recommended end pressure loss has been exceeded

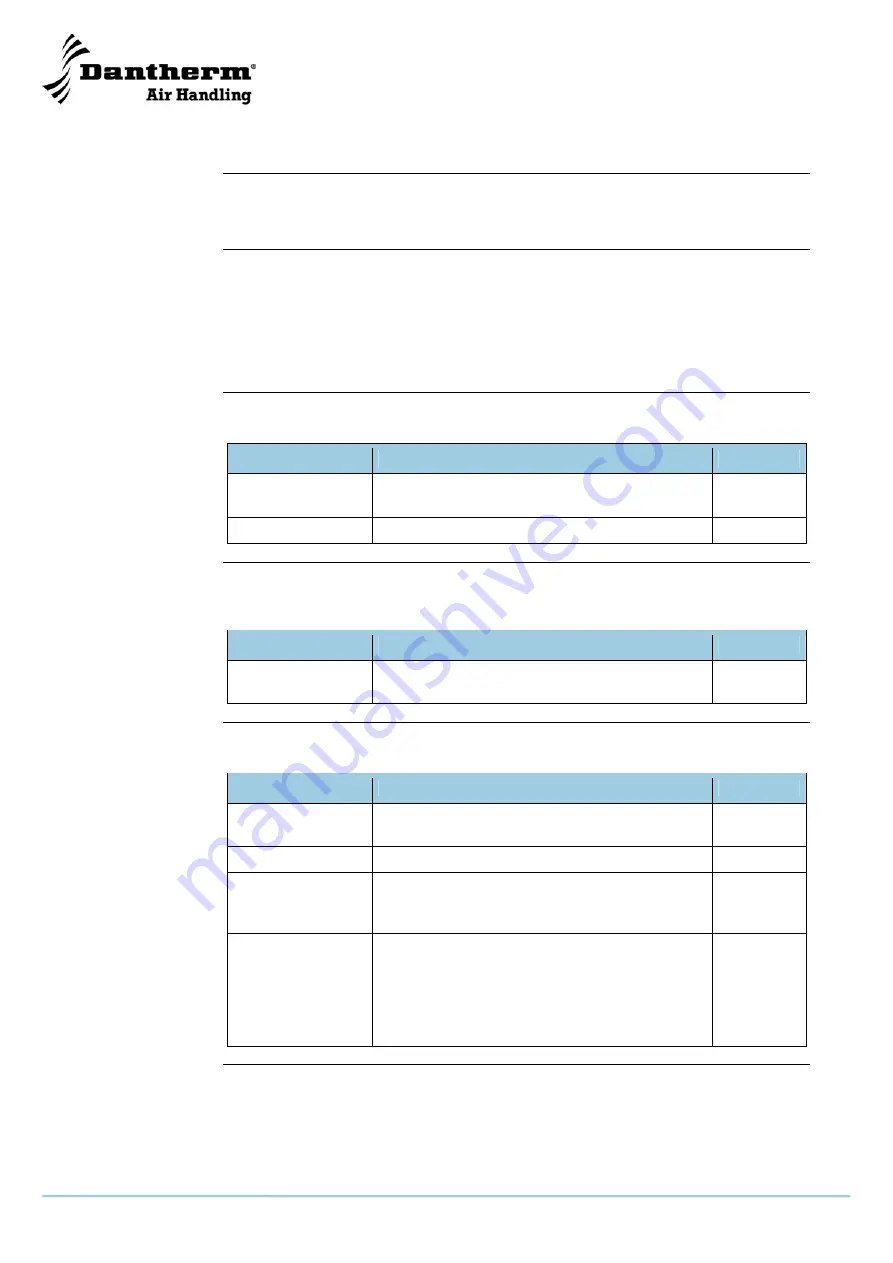

4 times annually

Check the following parts at least 4 times annually to ensure optimum operation:

Component

Service

Ref.

Rotary heat

exchanger

Inspection/tightening of belt

Page 20

Fan

Inspection/tightening of pulley

Page 18

5000 operation

hours/annually

Check the following parts after 5000 operation hours and at least once annually to

ensure optimum operation:

Component

Service

Ref.

Fan

The ball bearings of large fans are lubricated

The ball bearings of large motors are lubricated

Page 18

Once annually

Check the following parts at least once annually to ensure optimum operation:

Component

Service

Ref.

Cabinet

Clean the cabinet

Check gaskets and lock fittings.

Page 17

Damper

Check the tightness

Page 32

Rotary heat

exchanger

Check that the rotor is clean and runs smoothly

Check the gasket brushes

Check the function of the driving system

Page 22

Cross-flow heat

exchanger

Check the heat exchanger

Check the bypass damper tightness and

lubricate the movable parts of the bars

connected to the damper motor

Clean the condensate tray, the outlet and the

drain trap

Page 20

Continued overleaf

14