19

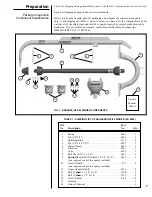

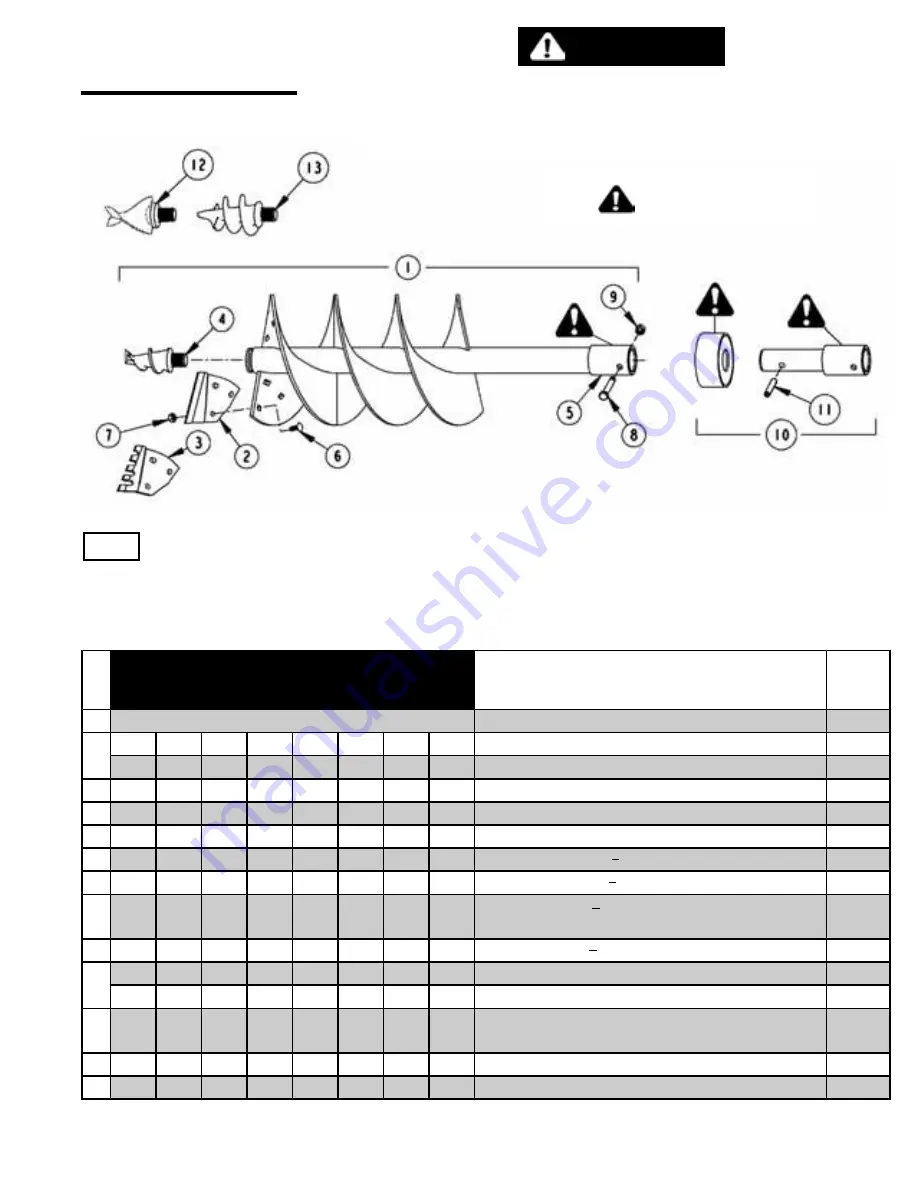

Auger

Assemblies

Ref.

No.

Part Number by Auger Diameter

Description

No.

Req’d

4"

6"

9"

12"

14"

16"

18"

24"

1

See next page for available augers.

Auger

1

2

7782

7783

Plain Cutting Edges (Weld On)

1 Set

7784

7790

7792

7794

7796

7798

Plain Cutting Edges (with Bolts & Nuts)

1 Set

3

7785

7791

7793

7795

7797

7799

Serrated Cutting Edges (with Bolts & Nuts)

1 Set

4

899

831

831

831

831

831

831

831

Standard Auger Point

1

5

6019

6019

6019

6019

6019

6019

6019

6019

Auger Adapter Replacement (for Field Welding)

1

6

784

784

784

784

784

784

Cutting Edge Bolt (3/8" 16 x 1" Carriage)

As Req’d

7

785

785

785

785

785

785

Cutting Edge Nut (3/8" 16 Hex)

As Req’d

8

6014

6014

6014

6014

6014

6014

6014

6014

Retaining Bolt (1/2" 13 x 3-1/4" Gr. 8, 1/2" of thread)

SPECIAL BOLT:

Use Genuine Danuser Replacement Only

1

9

1056

1056

1056

1056

1056

1056

1056

1056

Retaining Nut (1/2" 13 Hex)

1

10

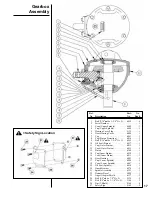

6080G 6080G 6080G 6080G 6080G 6080G 6080G 6080G Auger Extension with Guard (7")

1

6204G 6204G 6204G 6204G 6204G 6204G 6204G 6204G Auger Extension with Guard (14")

1

11

6239

6239

6239

6239

6239

6239

6239

6239

Coiled Pin (1/2" x 2-3/4")

SPECIAL PIN:

Use Genuine Danuser Replacement Only

1

12

1937

1937

1937

1937

1937

1937

1937

Special Duty Auger Point

1

13

6210

6210

6210

6210

6210

6210

6210

Aggressive Duty Auger Point

1

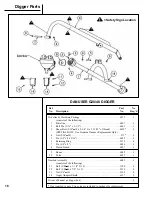

Augers have replaceable points and edges. Serrated cutting edges (Ref. No. 3) and optional points (Ref. No. 12 and

Ref. No. 13) are available to aid penetration in tough digging conditions. Flights are replaceable except on 4" and 6",

where the flight is a continuous spiral. Cutting edges on 4" and 6" augers are welded on the auger.

NOTE

When using an extension, Ref. No. 8 (PN 6014) and Ref. No. 9

(PN 1056) should be relocated from the auger adapter to the

extension adapter, and Ref. No. 11 (PN 6239) should be used to

attach the auger to the extension to avoid possible entanglement.

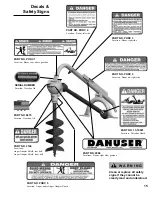

D A N G E R

AUGER ASSEMBLIES FOR 2" ROUND SPINDLES

= Safety Sign Location