12

www.danvex.fi

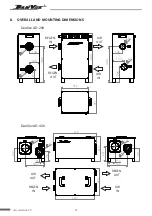

Installation diagram outside the dehumidification circuit

•

If the regeneration air inlet and the regeneration air outlet are connected to the same area, the duct

sockets must be at least 2 meters apart to avoid hot and humid air entering the regeneration air inlet.

•

The regeneration air outlet must have a certain slope to ensure that hot and humid air can be evacuated

smoothly.

•

The need for ducting for process air inlet and outlet depends on the size of the interior space

and the distance from the dehumidified area to the dryer.

•

If the room temperature is low, such as in cold stores, the dehumidifier and air water must be thermally

insulated to prevent condensation

.

3.8

Electrical connection

Be careful! All work on electrical equipment must be carried out in accordance

with the standards of the country in which the equipment is used,

and only by qualified experts

!

•

It is forbidden to connect the dehumidifier to the mains, the power and frequency of which

are outside the nominal values of the dehumidifier

;

•

Before connecting to the power supply, check that the voltage and frequency fluctuations

at the connection point do not exceed

±10%;

•

The equipment must be earthed and a power disconnect must be provided to ensure

that the device is disconnected during inspection and maintenance

.

•

The fuse rating of the power supply must match the power and type of the device.

The fuse must be installed near the device. The choice of power cable and main fuse

must match the operating power of the dehumidifier

.

3.9

Connecting external humidity sensors

The electrical wiring for the sensors can be pre-wired and provided with terminals for connecting

external control components.