RS485-2 Baud rate

RS485-2 Address

RS485-2 Protocol

RS485-2 Communication

status

Software version

Dew point

Absolute humidity

0 - no alarm 100-990。1=10hours

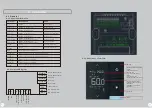

Code

Parameters

Default

Precision

Range

R01

R03

R04

R05

R06

R07

H01

H02

D01

D02

D03

F01

F02

F03

F04

F05

F06

F07

F08

F09

F10

F11

F12

P01

P02

P03

O07

O09

O10

O11

Humidity set(dehumidify)

Air damper automatic

close/open value

Air damper humidity

differential

Indoor temp. set

Humidity set

(humidify)

Humidity differential

(humidify)

Air damper automatic

close/open

Filter alarm hour

Defrost interval

Defrost stop

Defrost start

AC fan speed set

Fan set under achieved

humidity

FAN1, DC fan motor

speed 1 voltage

FAN1, DC fan motor

speed 2 voltage

FAN1, DC fan motor

speed 3 voltage

FAN1, DC fan motor

speed 4 voltage

FAN1, DC fan motor

speed 5 voltage

FAN2, DC fan motor

speed 1 voltage

FAN2, DC fan motor

speed 2 voltage

FAN2, DC fan motor

speed 3 voltage

FAN2, DC fan motor

speed 4 voltage

FAN2, DC fan motor

speed 5 voltage

50%

50%

3%

25°C(77°F)

70%

3%

1

200

40 minutes

10 minutes

17°C(62°F)

1

1

500(5V)

600(6V)

700(7V)

800(8V)

900(9V)

400(4V)

500(5V)

600(6V)

700(7V)

800(8V)

0

1

0

1%

1%

1%

0.5°C(1°F)

1%

1%

/

1

1 minutes

1 minutes

1°C(2°F)

/

/

10(0.1V)

10(0.1V)

10(0.1V)

10(0.1V)

10(0.1V)

10(0.1V)

10(0.1V)

10(0.1V)

10(0.1V)

10(0.1V)

F08~950

F09~950

F10~950

F11~950

0-4800

1-9600

1~255

1%-99%

1%-99%

1%-10%

5~35°C(41~95°F)

1%-99%

1%-10%

0 - no in use

1 - in use

30~60 minutes

1~20°C(34~68°F)

400~950

F03~950

F04~950

F05~950

F06~950

400~950

0-General open protocol

0 - abnormal / 1 - normal

6.

11

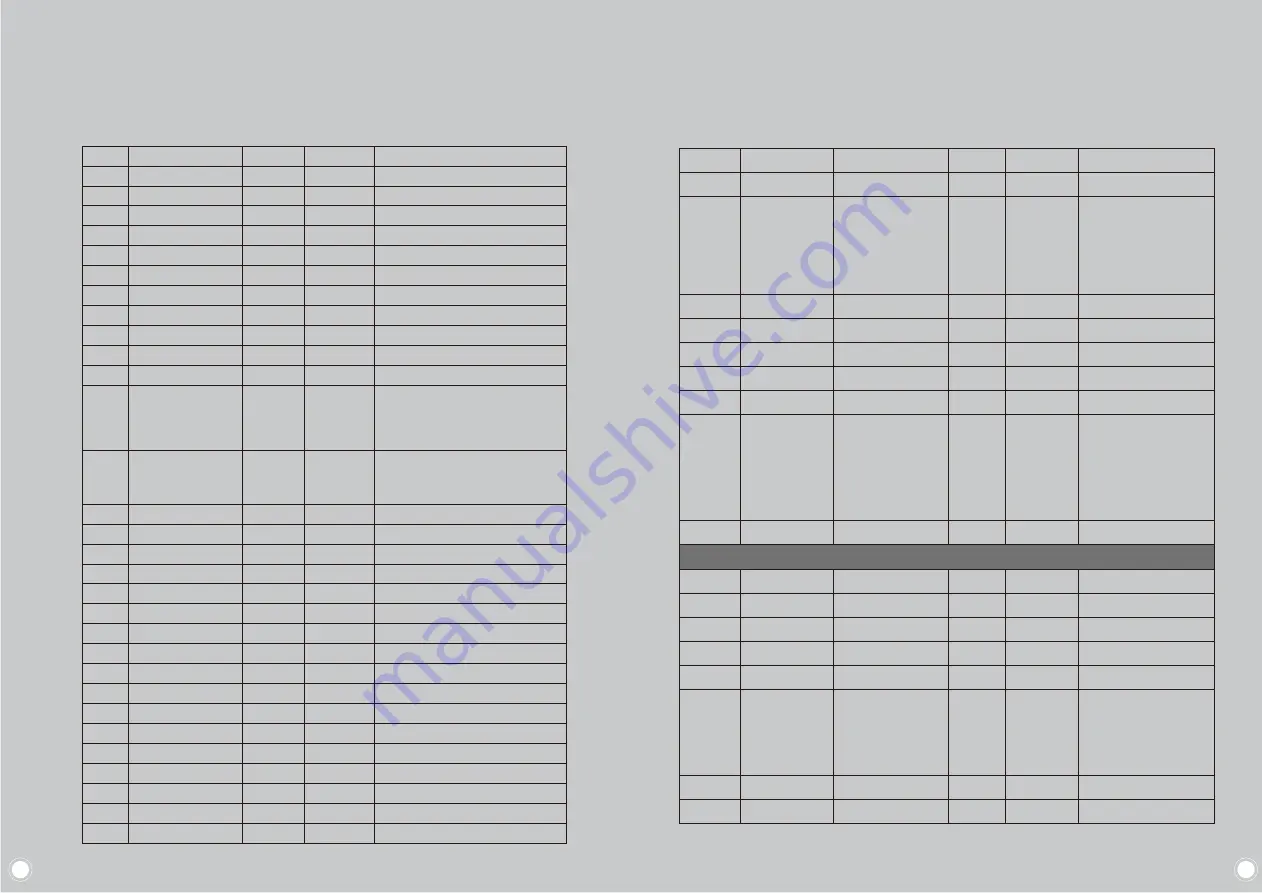

Parameters Code Description

Address

Function Code

Byte

Read Only or

Read/Write

Object

Read/Write

2 bytes

2 bytes

2 bytes

2 bytes

2 bytes

2 bytes

2

bytes

2

bytes

2

bytes

2

bytes

2

bytes

2

bytes

2

bytes

2

bytes

2

bytes

2

bytes

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

0 - OFF 1 - ON

1 - 1st fan speed

2 - 2nd fan speed

3 - 3rd fan speed

4 - 4th fan speed

5 - 5th fan speed

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

0x1001

0x1002

0x1003

0x1004

0x1006

0x1008

0x101B

0x101C

0x101D

0x2001

0x2002

0x2003

0x2004

0x2005

0x2006

0x2007

0x2008

03/03/16

03/03/16

03/03/16

03/03/16

03/03/16

03/03/16

03/03/16

03/03/16

03/03/16

03

03

03

03

03

03

03

03

ON/OFF

fan speed

air damper close/open

humidity set

air damper automatic

humidity set

air damper automatic

close/open

temperature set

working modes

humidification set

indoor temperature

sensor

indoor humdity sensor

external temperature

sensor

external humidity

sensor

fan running time

failure

dew point

absolute humidity

0 - close 1 - open

1~99%

1~99%

0 - not in use 1 - in use

5~35°C

0 - dehumidification

1 - dehumidification

2 - dehumidification

3 - humidification

4 - humidification

5 - humidification

1~99%

1=10 hours

2

bytes

Read Only

bit0:built sensor failure

bit1:external sensor failure

bit2:filter alarm

bit3:minimum absolute

humidity protection

bit4:in defrost

Data

6.

12

RS485-2 Modbus communication protocol

Function code description:

function 03 – read function 06 – write single function 16 – write multiple

25

26

1 - low speed

2 - medium speed(DC motor fan:1,2 -

low;3,4,5 - high)

3 - high speed(DC motor fan:1,2 - low;3,4 -

medium;5 - high)

1 - turns off 3 minutes later after achieved

the set humidity

2 - keeps working after achieved the set

humidity