·

Purpose of the Manual

Through the manual, you can understand the structure, installation specifications, control principles, process flow and

operation methods of the cabinet-type dehumidifier.

·

Knowledge Required

You need to have knowledge of automatic control and air handling to understand the manual.

·

Contents Included

The manual explains in detail the functions, operation, daily maintenance and troubleshooting of the cabinet-type dehumidifier.

·

All rights reserved

Copying of this manual, or part of it, is forbidden without prior written permission from

DANVEX

.The warranty and technical

support of this product are only valid in the country or region of purchase.

Foreword

UL/484-2014 American standard for Room air conditioners

ANSI/UL94 American standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances

UL/969 American standard for marking and labeling systems used for permanent product identification

UL/474-1993 American Safety Standard for Dehumidifiers

GB/T191-2008 China National Standard for Packaging - Pictorial Markings for Handling of Goods

ANSI/AHAM DH-1-2008 ANSI/AHAM Standard for dehumidifiers

This unit must be operated by trained professionals, otherwise it will cause casualties or property damage.

Please read and understand this manual thoroughly before operation to avoid damage to the unit or personal injury or death caused by

misoperation.

Please contact the supplier or the manufacturer if there are any issues arises that are not stated in this manual.

Standards and Codes:

GB/4706.32-2004 China National Standard No. GB/4706.32-2004, Code of household and similar electrical appliances Particular

requirements for heat Pumps, air-conditioner and dehumidifier

IEC 60335-2-40 International safety Standard for electric heat pumps, including sanitary hot water heat pumps, air-conditioners, and

dehumidifiers incorporating sealed motor- compressors

Please keep this manual for later reference.

GB/T16803-2018 China National Standard No. GB/T16803-2018, Code of of heating, ventilating, air conditioning and air cleaning

terminology

GB/T2518 China National Standard No.GB/T2518, Code of of continuously hot-dip zinc and zinc alloy coated steel sheet

GBJ16-87 China National Standard No.GBJ16-87, Code for fire protection of building design

GB/T19411-2003 China National Standard for dehumidifiers

GB/T17791-2007 China National Standard No. GB/T17791-2007, Code of of Specification for seamless copper tube for air conditioning

and refrigeration field service

GB/755-2000 China National Standard No. GB/755-2000, Code of of Rotating electrical machines--Rating and performance

GB/50016-2006 China National Standard No.GB/50016-2006, Code of Design on Building Fire Protection and Prevention

GB/50243-2002 China National Standard No. GB/50243-2002,Code of acceptance for construction quality of ventilation and air

conditioning works

GB/50019-2003 China National Standard No. GB/50019-2003,Code for Design of Heating Ventilation and Air Conditioning

GB/50015-2019 China National Standard No. GB/50015-2019,Code for design of building water supply and drainage

GB/T7725-2004 China National Standard No. GB/T7725-2004, Code for room air conditioners

GB/T18883-2002 China National Standard for indoor Air Quality Standard

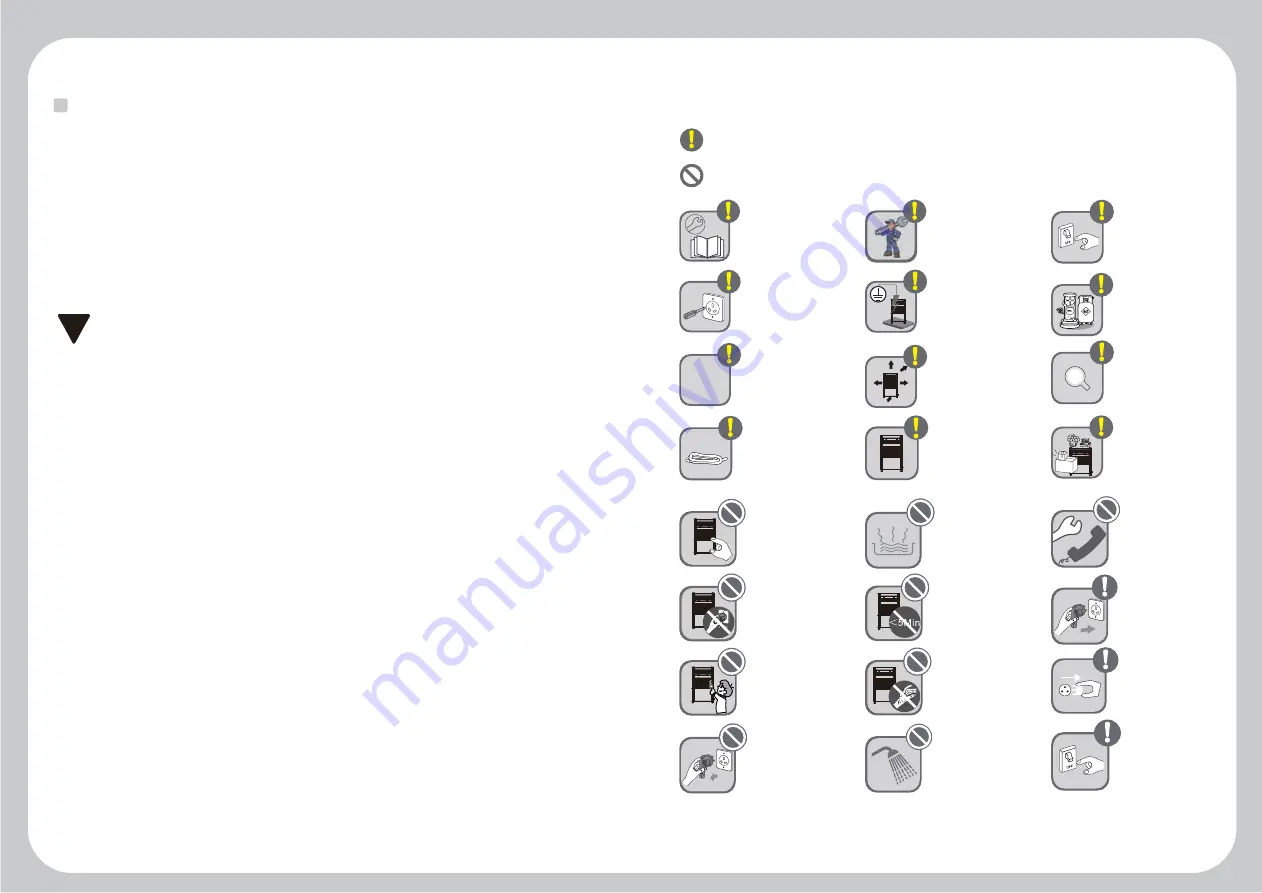

NOTE

Warning

This symbol indicates the rules that must be followed! If it is not strictly followed,

it may cause mild to moderate damage to the machine or signs of personal injury.

This symbol indicates actions that must be prohibited!! If not strictly followed,

it may cause serious damage to the machine or personal injury or death.

When a problem occurs (such as a

burning smell, etc.), please turn

off the unit and unplug the power

cord. (Cut off the power supply).

Please follow this manual for

installation. Please read this manual

carefully before running or servicing

the unit.

The space above the equipment

installation is at least 50 cm, the

rear and the left and right sides

are at least 100 cm, and the front

is at least 200 cm.

Before installation, please check

whether the power cord used is

consistent with the power required

on the nameplate, and check the

safety of the power supply.

Be sure to use special accessories

and parts during installation.

Otherwise, it may cause water

leakage, electric shock, fire and

other accidents.

The power connection of this unit

adopts Y-type connection, and the

diameter of the power cord should

be large enough. If the power cord

is damaged, in order to avoid danger,

the power cord should be replaced

by the manufacturer or professionals.

Do not insert your fingers or objects

into the air outlet or return air grille.

Do not start or stop the unit by

pulling out the plug.

Do not allow children to operate

the unit.

The unit can only be cleaned after

shutting down and cutting off the

power supply, otherwise you may

get an electric shock or be injured.

The installation should be carried

out by the seller or qualified

professionals, please do not install

the unit by yourself. Incorrect

installation may cause accidents

such as water leakage, electric

shock or fire.

The unit should be grounded, and

the power socket must be equipped

with a ground wire to ensure that

the machine is effectively grounded

through the power socket to avoid

the risk of electric shock. Do not

connect the ground wire to gas

pipes, water pipes, lightning rods or

telephone wiring.

Drainage pipes should be installed

correctly in accordance with the

installation instructions to ensure

proper drainage, and insulation

measures should be taken to avoid

condensation.Improper installation

of pipes will cause water leakage.

Volatile liquids such as thinner or

gasoline will damage the

appearance of the unit. (Only use a

soft dry cloth and a damp cloth

dampened with a neutral detergent

to clean the casing of the unit).

Once the unit is turned on, it must

run for at least 5 minutes before it

can be turned off, otherwise it will

affect the compressor oil return.

Do not operate the unit with

wet hands.

Do not pour or rinse the unit with

water, otherwise it may cause

malfunction or risk of electric shock.

When the unit is not used for a

long time, please cut off the power

supply of the unit.

After the unit is installed, electric

leakage test should be carried out.

Do not repair the unit by yourself.

Wrong maintenance will cause

electric shock or fire.

Do not step on the unit, and do

not place objects on or on the air

inlet and outlet of the unit.

After installation, please check

and confirm whether the

connections of drain pipes, ducts

and wires are correct to prevent

water leakage, refrigerant leakage,

electric shock or fire accidents.

Do not use or store flammable

and explosive dangerous goods

next to the unit. There should

be at least 1.5m between the

combustible surface and the unit.

For units using line control,

the line controller store must

be connected first, otherwise

the line controller will be unusable.

DANVEX

assumes no responsibility for personal injury or equipment damage caused by improper installation, commissioning,

unnecessary maintenance, and failure to follow the regulations and instructions in this manual.

SPECIAL

ACCESSORIES

SPECIAL