3.3 Inspection

3.

6

Ground Level

It should be stored under a cover to prevent the intrusion of dust, frost and rain.

§

If the duct connected to the unit has been arranged, check whether the duct is appropriate.

§

(Note: When installing the equipment, consider retaining enough space for maintenance.)

Disassemble the shipping packaging of the unit and inspect it to ensure that it is not damaged during

transportation.

The equipment should be placed close to the socket equipment and easily connected.

The cabinet type dehumidifier can be installed in many places, depending on the needs of the owner. If

required, it can also be used in combination with the existing power system or the existing air duct system. This

chapter covers the instructions required for installation, read before the equipment is installed, will help you to

arrange the work correctly.

It is not advisable to remove the shipping packaging.

§

If the environment and installation conditions are not satisfactory, please contact the relevant design and

§

technical personnel of the manufacturer.

The unit is heavy and can be moved on flat ground. If the distance is long, it can be lifted and transported on

the base of the unit with a hydraulic truck. In order to prevent damage to the unit and personal injury, it is

recommended to use lifting equipment. Cabinet-type dehumidifier must be treated with care. When the unit is

moving, a crane or forklift can be used. When using a crane, a suitable lifting point should be selected. The lifting

point cannot touch the motor, control system and exposed pipe fittings to avoid damage to the unit.

3.5 Location Requirement

Cabinet-type dehumidification equipment must be installed horizontally. Please use a level to measure the

flatness of the equipment to prevent residual condensate, which will cause the dehumidifier to leak water and

damage the entire environment.

3.1 Introduction

In order to ensure the quality and reliability of the dehumidifier, each unit has been inspected before leaving

the factory.If the unit needs to be stored for a period of time before installation, the following items should be

noted:

3.2 Delivery & Storage

The location of the equipment should be avoided physical damage.

§

In order to obtain the best operating status and fault maintenance services, cabinet-type dehumidification

equipment should be installed indoors. During installation, there should be maintenance space at the rear of the

dehumidification equipment to facilitate future inspection and maintenance of the equipment. For cleaning and

maintenance purposes, it is very important to keep the necessary and compact service space. In order to prevent

condensation inside the dehumidification equipment, the unit should not be exposed to an environment with a

temperature lower than the dew point of the processing air.

If you find any damage, please contact the manufacturer.

§

3.4 Unit Movement

3

.

Installation

If the air outlet is connected to a duct, the size of the treated air duct should comply with the

recommended value of ISO7807. For the installation of pipe joints of ducts and elbow flanges, the bolt length

shall not exceed 20mm. For an ideal installation, the air is drawn from the central area of the room,

dehumidified, and then transported to each individual room, such as a bedroom and an office. Install the

return air outlet of the dehumidification unit and

When connecting the outlet to the pipeline, the following recommendations should be noted:

Minimize the length of the air duct in order to reduce the static pressure loss of the air system.

§

In order to ensure performance, all rigid (galvanized) pipe connections must be airtight.

§

3.

7

Duct Connection

The duct should be insulated to avoid condensation on the outer wall of the duct when the temperature

§

of the airflow in the duct drops below the dew point temperature of the outside air, which may lead to

duct corrosion; and energy loss can be avoided.

The pipeline directly installed on the dehumidification unit should be fully supported to reduce the load

§

and pressure caused by the gravity and operation of the pipeline.

If the system is introduced into the dehumidification unit from outdoor fresh air, the air inlet should be

§

sufficiently high from the ground to prevent the inhalation of dust and debris. The entrance must be far

away from possible pollution sources, such as energy waste gas, steam and harmful gases.

In order to ensure the best dehumidification effect, the fan outlet should be equipped with a diffuser.

§

The dehumidification equipment can be installed in a room where dehumidification is required or in a

§

separate room.

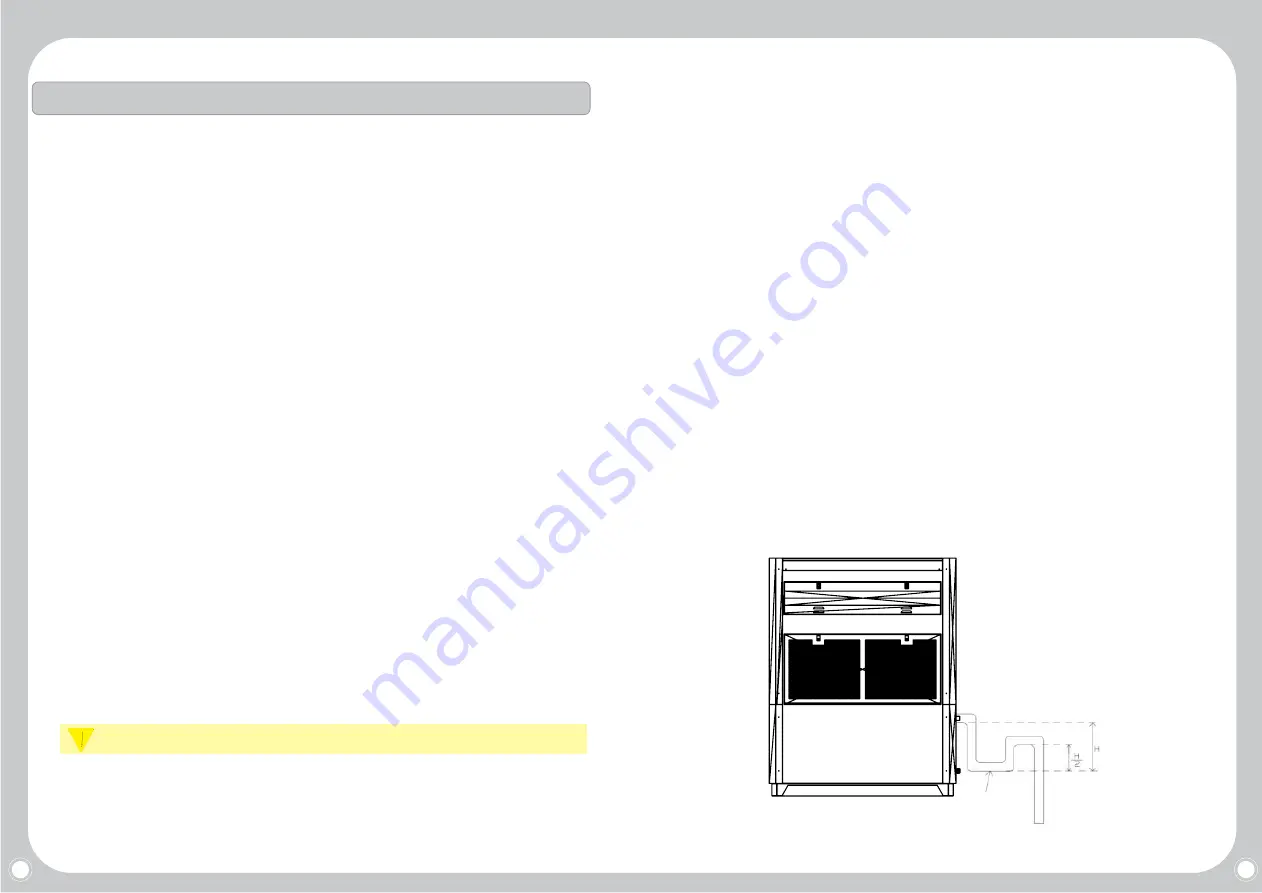

When the outlet of the drain pipe is an indoor unit with negative pressure, the drain pipe must use a water trap.

§

3

.

8

Negative-pressure Drainage Pipe Installation

The installation of PVC drainage pipes requires 5mm insulation to prevent condensation.

§

9

10

Condensate trap