R

www.danvex.fi

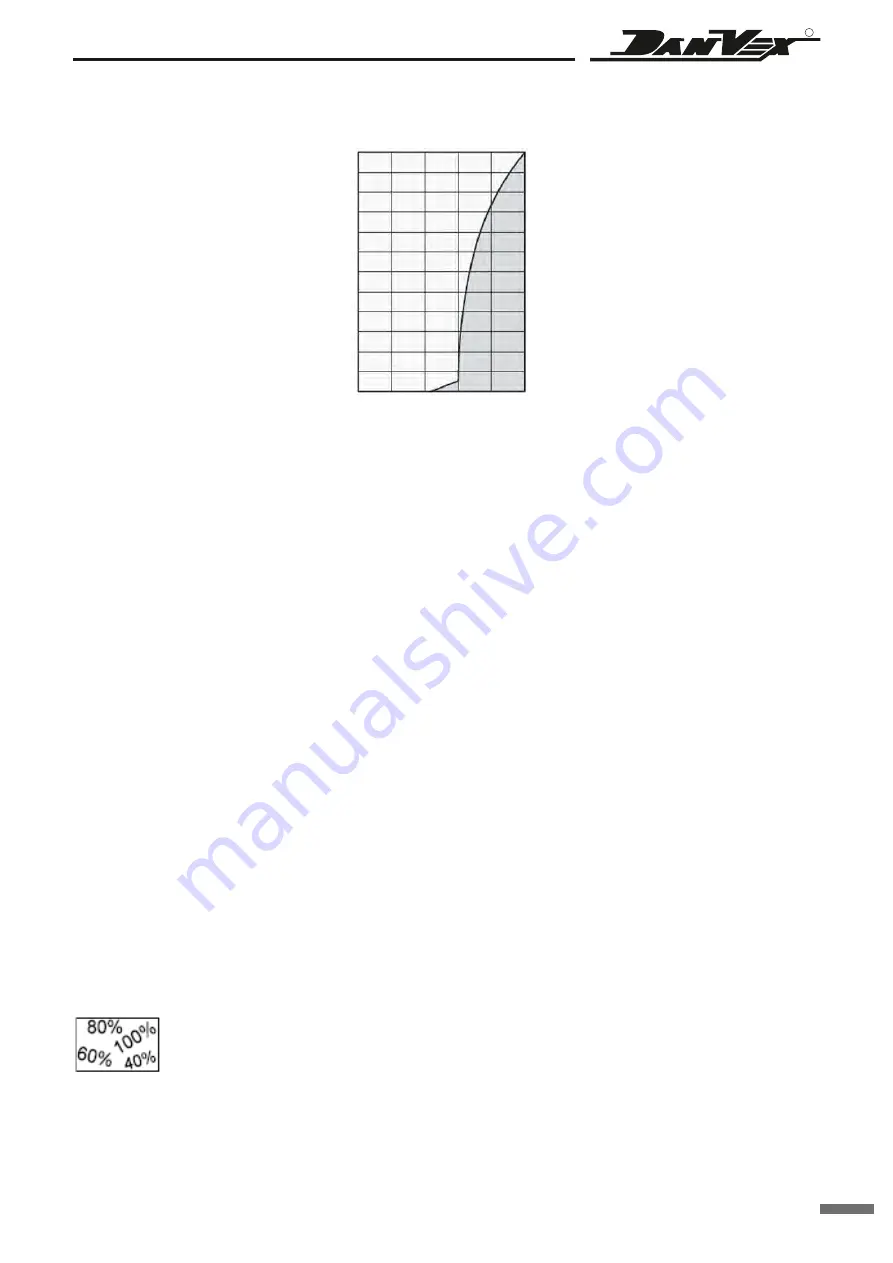

The below diagram shows an example of metal corrosion rate at different air humidity levels.

3

As you can see on the graph the rate of corrosion is insignificant at the relative humidity (RH)

below 50%, and it can be disregarded at RH below 40%. But at the relative humidity above

60% the rate of corrosion increases considerably.

This moisture damage example applies also to many other materials, such as powders,

packaging, wood, electric equipment or electronic devices.

There are two different ways of achieving required humidity in a building being dried out:

1. By heating with further air exchange:

The ambient air is heated to absorb the moisture and then it is discharged to the atmosphere.

However the total energy output is lost during the moist air discharging to outside.

2. By the air dehumidification:

The moist air in an enclosed room is continuously dehumidified by the condensation principle

or by other dehumidification method.

In terms of energy consumption the air dehumidification has one essential advantage:

the energy expenditure requirements are limited by the air volume in the existing room

only.

The heat generated during the air dehumidification process (heat of condensation) slightly

increases the air temperature in the room.

When properly used the dehumidifier consumes about 25% of the energy that would be

needed for the „heating and ventilation".

The relative and absolute air humidity

1 m3 of dry air weighs about 1,2 kg at 20° C.

The ambient air is a gas mixture that always contains a certain amount of water in the form of

water vapor. The maximum water vapor content in the air (moisture content of the saturated

air) depends on its temperature and pressure.

0

20

40

60

80

100

30

60

90

120

0

Air relative humidity, %

Corrosion time