Shutdown protection: When the dehumidifier is turned off under normal circumstances, the fan will keep

§

working for 3 minutes to ensure the heat radiated.

Fan working mode: After the humidity is reached, you can choose whether the fan is running or not.

§

High-temperature protection: The unit is designed with high-temperature protection to prevent the

§

compressor from burning under continuous operation at high temperature.

Low-pressure protection: Prevent the compressor from burning out due to continuous operation without

§

refrigerant in the system.

The system design has added an energy-saving heat exchanger, which adopts a combined design of a

§

liquid separator and a heat exchanger, which can effectively adjust the liquid flow function of the system,

and can also maximum the dehumidification capacity to ensure the optimal operation of the compressor.

The system adds a dry filter to effectively prevent the turbid impurities in the system from blocking the

expansion valve or capillary tube.

The compressor is the core part of the dehumidifier. Its performance characteristics directly affect the

performance and characteristics of the cabinet dehumidifier. The compressor is the core of the entire

dehumidification system and the source of system power. The power of the entire dehumidification is all

provided by the compressor. The compressor is equivalent to moving a physical object from a low potential

position to a high potential position. In the dehumidifier, its purpose is to compress the low-temperature gas

into high temperature through the compressor. Finally, the gas exchanges heat with other media in the heat

exchanger. The compressors are all imported brands.

The heat exchanger adopts hydrophilic membrane fins, the heat exchange efficiency is increased by 20%,

§

thus to reduce the unit size and weight. The high-quality thermal insulation material increases the

thermal insulation effect by 15%.

2.5.5 Throttling Section:

The self-developed dehumidifier controller has more powerful functions, and the overall operating

§

performance of the unit is higher, ensuring uninterrupted operation of the equipment.

2

.

5

.

3

Dehumidification Section :

The defrosting adopts a patented structure device to ensure the stable operation of the refrigeration

§

system. The unique defrosting is gradually adopted without affecting the operation of the system.

2.5.4 Compressor:

The throttling component is one of the four indispensable components of the refrigeration system. Its

function is to throttle and reduce the pressure of the high-pressure liquid from the condenser, so that the

liquid refrigerant vaporizes and absorbs heat at low pressure (low temperature). Therefore, it is an important

part to maintain the high pressure in the condenser and the low pressure in the evaporator. Due to the direct

expansion method, the cooling loss is small and the efficiency is high. At the same time, it also has the

function of preventing liquid shock to protect the compressor and abnormal overheating. The expansion

valve has a stable degree of superheat, which makes the system run stably.

Motor overload and short circuit protection: The supply fan motor and the compressor motor have

§

overload and short circuit protection functions.

2.5.6 Controller Protection:

Power-on protection: When the dehumidifier is turned off under normal circumstances, it will take 3

§

minutes to restart the protection when it is turned on again.

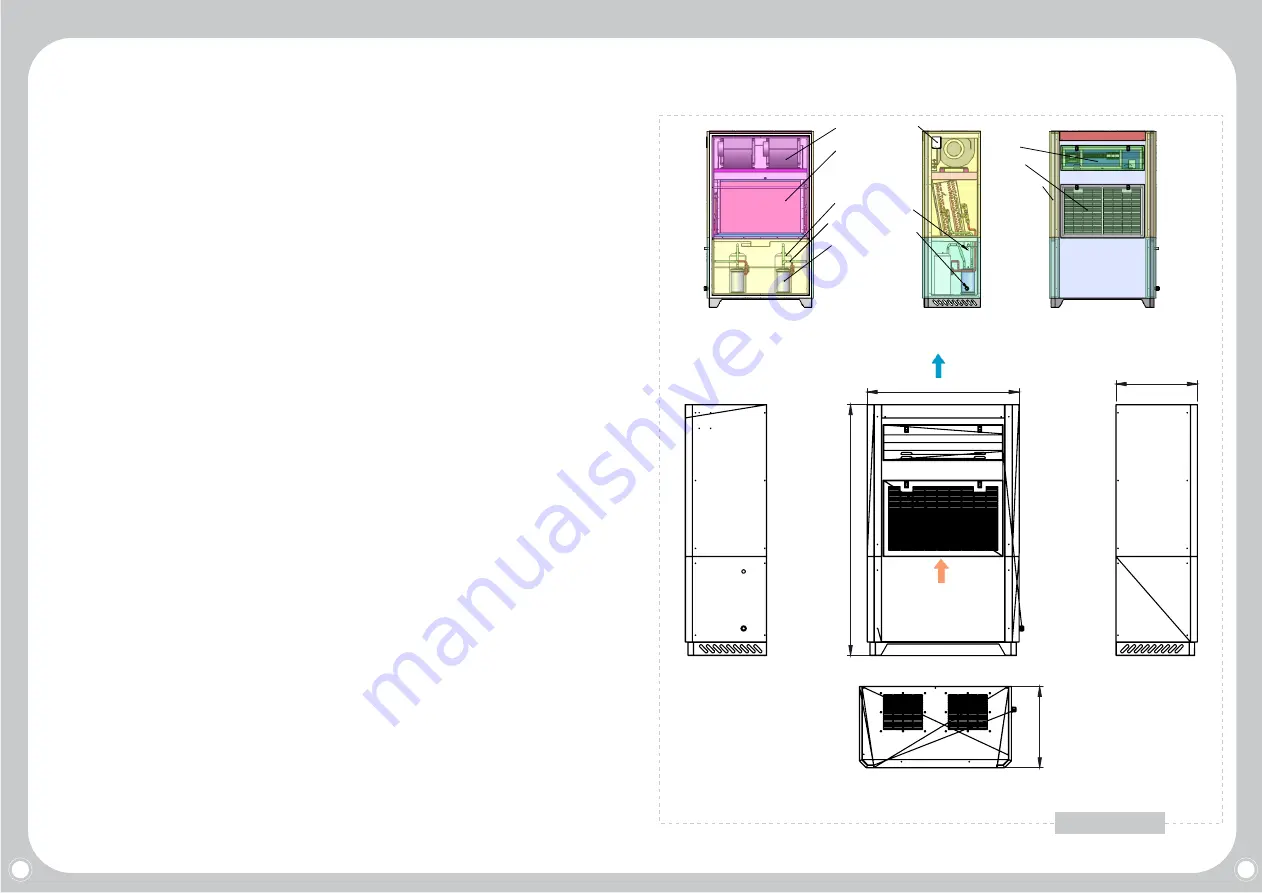

2.5.7 Structure & Dimension

filter

electic box

steel housing

nameplate

condensate drain hole

power cord

fan

heat exchanger

gas-liquid seperator

compressor

cooling system

DEH-3K/5K

1850

1122

600

600

condensate

drain pipe

power

cord

5

6