9

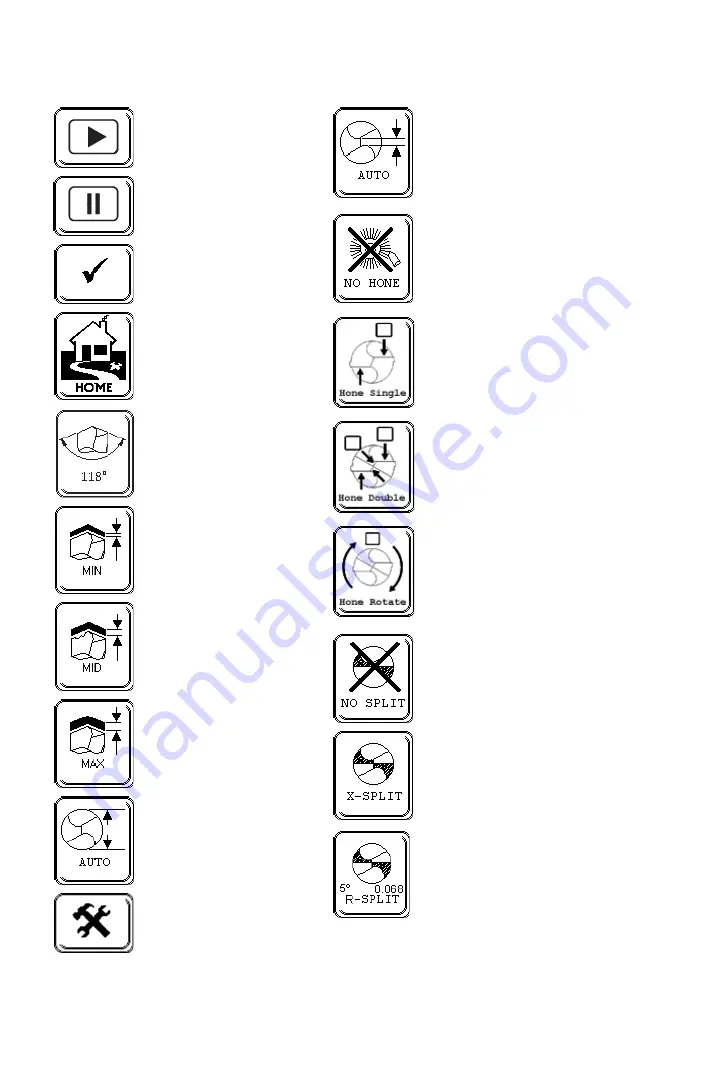

Cycle Start (Green)

Web Thickness

Detection Screen

No Hone Selected

No Split or No Grind Selected

Standard Split Point

Radius Split Point

Cycle Stop (Amber)

Continue

Return to Home

Point Angle Selection

Minimal Material

Removal

Mid-range Material

Removal

Primary and secondary

cutting edge hone

Hone primary cutting

edge after sharpening

Rotate drill in hone brush

Maximum Material

Removal

Diameter Detection

Auto Or Manual

Tools Button To Access

Second Page

Touch Screen Icon Reference

Summary of Contents for XPS-16+

Page 1: ...Operating Instructions XPS 16 CNC Drill Grinder and Sharpener ...

Page 2: ......

Page 40: ...37 Notes ...

Page 41: ...38 ...